Nexterra biomass gasification ready to displace up to 60% fossil fuels in lime kilns, 100% in boilers

After two years of biomass gasification testing at the company’s product development centre in Kamloops, British Columbia, Nexterra Energy Corp. has confirmed that renewable synthesis gas, or “syngas”, produced by its gasifier has the ability to displace at least 60 per cent of fossil fuels used in lime kilns. Depending on the biomass feedstock and existing equipment configurations, 95 per cent substitution may be possible at many pulp mills, and up to 100 per cent in certain types of boilers.

After two years of biomass gasification testing at the company’s product development centre in Kamloops, British Columbia, Nexterra Energy Corp. has confirmed that renewable synthesis gas, or “syngas”, produced by its gasifier has the ability to displace at least 60 per cent of fossil fuels used in lime kilns. Depending on the biomass feedstock and existing equipment configurations, 95 per cent substitution may be possible at many pulp mills, and up to 100 per cent in certain types of boilers.The ability to convey syngas from where it is produced and combust it inside existing thermal process equipment could lead to dramatic cost and CO2 emissions reductions in a number of industries. The system could be used in multiple carbon-heavy industrial applications including pulp mill lime kilns, power boilers, rotary dryers and calciners commonly found in mineral processing, mining, cement and ethanol production industries.

Nexterra’s direct fire biomass gasification system is now ready for demonstration at commercial scale. Once proven at this scale, we plan a full commercial rollout for industries such as pulp and paper, wood products, mining and others that want to reduce operating costs while lowering their carbon footprint. Up to now, these customers were limited to using either natural gas or fuel oil. Syngas offers a cheaper, carbon-neutral and renewable fuel alternative. - Jonathan Rhone, Nexterra President and CEO

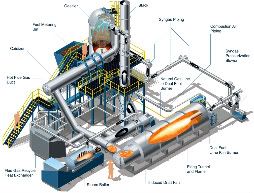

Nexterra’s first generation gasification systems are close-coupled with heat exchangers to generate hot water, steam or hot air. The new direct fire application enables customers to decouple the process by producing syngas in one location and combusting it elsewhere on a site. The product development program included process simulation of end user equipment, as well as testing of specialized syngas conveying, pressurization and burner equipment at Nexterra’s test facility (images: the gasification plant with the firing tunnel and boiler that were used during the testing program, click to enlarge).

Nexterra’s first generation gasification systems are close-coupled with heat exchangers to generate hot water, steam or hot air. The new direct fire application enables customers to decouple the process by producing syngas in one location and combusting it elsewhere on a site. The product development program included process simulation of end user equipment, as well as testing of specialized syngas conveying, pressurization and burner equipment at Nexterra’s test facility (images: the gasification plant with the firing tunnel and boiler that were used during the testing program, click to enlarge).Nexterra’s technological breakthrough makes the switch from fossil fuels to syngas an attractive option for North America’s more than 100 kraft pulp mills and other industrial sites which face record high natural gas prices and, in British Columbia’s case, new carbon taxes:

energy :: sustainability :: lime kilns :: pulp mills :: fossil fuels :: emissions :: fuel switching :: biomass :: bioenergy :: gasification :: syngas :: efficiency ::

energy :: sustainability :: lime kilns :: pulp mills :: fossil fuels :: emissions :: fuel switching :: biomass :: bioenergy :: gasification :: syngas :: efficiency :: Installation of a Nexterra direct fire gasification system at an average sized commercial pulp mill lime kiln, for example, has the potential to reduce natural gas consumption by more than 800,000 gigajoules (GJ) per year, the equivalent amount of natural gas needed to heat 5,000 residential homes. In addition, such a system could save a mill several million dollars annually and reduce greenhouse gas emissions by more than 25,000 tonnes per year.

The direct fire testing program was supported by Sustainable Development Technology Canada (SDTC), a not-for-profit foundation created by the Government of Canada, as well as by Canada’s National Research Council/IRAP Program, Natural Resources Canada and Ethanol BC.

Nexterra will present a paper on its direct fire program for lime kilns and boilers at the TAPPI 2008 Engineering, Pulping and Environmental Conference in Portland, OR, on August 27, 2008.

Nexterra Energy, based in Vancouver, BC, Canada, is a leading developer and supplier of advanced gasification systems that enable customers to self-generate clean, low cost heat and/or power using waste fuels "inside-the fence" at institutional and industrial facilities. Nexterra gasification systems provide a unique combination of attributes including design simplicity, reliability, versatility, ultra-low emissions, low cost and full automation to provide customers with a superior value proposition compared to conventional solutions.

SDTC is an arm’s-length foundation which has received $1.05 billion from the Government of Canada as part of its commitment to create a healthy environment and a high quality of life for all Canadians. SDTC operates two funds aimed at the development and demonstration of innovative technological solutions. The $550 million SD Tech Fund supports projects that address climate change, air quality, clean water, and clean soil. The $500 million NextGen Biofuels Fund supports the establishment of first-of-kind large demonstration-scale facilities for the production of next-generation renewable fuels. SDTC operates as a not-for-profit corporation and has been working with the public and private sector including industry, academia, non-governmental organizations (NGOs), the financial community and all levels of government to achieve this mandate.

The National Research Council Canada is recognized globally for research and innovation, and is a leader in the development of an innovative, knowledge-based economy for Canada through science and technology. The National Research Council Canada Industrial Research Assistance Program (NRC-IRAP) provides a range of both technical and business oriented advisory services along with potential financial support to growth-oriented Canadian small - and medium-sized enterprises. Working directly with these clients, NRC-IRAP supports innovative research and development and commercialization of new products and services. The program is delivered by a network of 260 professionals in 100 communities across the country. Funds provided under this program are done on a cost-share basis with their clients.

Natural Resources Canada (NRCan) puts innovative science and technology to work so Canada’s natural resources sector can continue to contribute to our quality of life, now and in the future. More information on the Government of Canada’s ecoENERGY Initiatives can be found here.

Ethanol BC is a non-profit R&D funding organization administered by FP Innovations. Grant funding now comes from a unique tax shifting mechanism established under regulation by the Provincial government. The program effectively allows forest companies operating bee-hive incinerators to pay a portion of their permit fees to Ethanol BC. These funds in turn are used to spur research and demonstration of new technologies that will ultimately utilize mill wood residues that are now being incinerated as wastes. The program has been in place since 2000 and is governed by a Board consisting of forest industry, provincial and federal government representatives.

Article continues

--------------

--------------

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Tuesday, August 19, 2008

Novel fungus helps beetles to digest hard wood - potential applications in next-gen biofuels

Microbes in the gut of insects are known to break down cellulose, but little is known about how, or whether, insects degrade lignin. This natural polymer helps plants stay upright and protects them from most forms of microbial attack.

According to Ming Tien, study co-author and Penn State professor of biochemistry and molecular biology, lignin is nature's "plastic" and any organism that wants to get to the sugars in a plant has to be able to get past this protective barrier. The scientists now suspect that the fungus produces enzymes that help the beetles degrade lignin.

Before this report, it was thought that insects are unable to extensively break down lignin, and that they get around the problem either by feasting on wood that has already degraded, or by living close to fungi that can degrade the wood for them.

But this theory fails to explain the ability of insects to feed and grow within healthy living trees.

How these insects are able to circumvent this "plastic wall" and get at the sugars behind it has remained a mystery, said Tien, who was recruited by Kelli Hoover, co-author and Penn State associate professor of entomology, and Scott Geib, lead author and Penn State doctoral student in entomology, to tease out an explanation.

The Asian longhorned beetle is one such insect that attacks healthy trees and bores through the hard wood to get at the succulent energy-rich matter inside. In the process, this invasive pest from China grows nearly 300-fold from being about the size of a grain of rice to a few inches in length.

Hoover and her colleagues speculated that the beetle could be harboring a community of microbes in the gut, which helps in breaking down lignin.

The researchers compared the chemical structure of non-degraded wood before and after it had passed through the gut of two wood-eating insects. To measure the degree of change in the lignin, they first fed pin oak wood to Asian longhorned beetles. Next they fed ponderosa pine wood to the Pacific dampwood termite, an insect that typically eats only dead wood.

Chemical analyses of feces from the two bugs indicated that they are able to alter the chemical structure of lignin by selectively adding or removing certain groups of molecules from the polymer. Such alterations make it easier for the insect to break down wood:

This means that the fungus has genes that then make enzymes. And the researchers have been able to detect messages from this [fungal] DNA, which get translated into enzymes.

While the scientists have identified the fungus residing in the gut of the Asian longhorned beetle, they have yet to find one in the gut of the termite.

According to Geib, the types of chemical changes the researchers see in the beetle are similar to those seen in the white-rot fungus. Changes they see in the termite are similar to those in the brown-rot fungus. And the chemical changes to the lignin are similar too.

However, Geib cautions that while the gut-borne fungus is certainly a key player in degrading wood, it may just be part of a bigger picture.

It is likely that there is an interaction among enzymes produced by the fungus, hundreds of bacteria within the insect gut, and the insect itself. It is a consortium that is doing the job.

If researchers manage to identify some of these key microbes, it might be possible to selectively target just those bacteria to impair the growth of Asian longhorned beetles, which have the potential to severely damage the lumber and maple syrup industry.

Both Geib and Hoover, who study Asian longhorned beetles, believe they may have stumbled upon a novel evolutionary adaptation in the insect world.

This type of fungus [in the Asian longhorned beetle] is known to cause disease in plants, said Hoover, whose work is funded by the Alphawood Foundation and the Penn State College of Agricultural Sciences. But this particular strain appears to be unique. It looks like these insects somehow acquired the fungus to live in their gut and help them break down wood.

She also points out that these fungi are more efficient than their free-ranging counterparts. While those fungi take months, even years, to break down wood, the gut-borne fungi seem to do it much faster.

Researchers say the speedy process could potentially be harnessed to produce biofuel.

Getting rid of the lignin barrier and making the cellulose more accessible is the most expensive and environmentally unfriendly part of making ethanol from biomass, said Geib. The team's discovery, he added, could lead to the potential development of cheaper and more efficient enzymes for converting wood into ethanol.

Other researchers on the paper include Timothy R. Filley, associate professor, department of earth and atmospheric sciences, Purdue University; Patrick G. Hatcher, the Batten endowed chair in physical sciences and professor of chemistry and biochemistry, and Rachel L. Sleighter, doctoral candidate, both at Old Dominion University; John E. Carlson, professor of molecular genetics, director of Schatz Center for Tree Molecular Genetics, School of Forestry; and Maria del Mar Jimenez-Gasco, assistant professor of plant pathology, both at Penn State.

Picture: The larva of Asian longhorned beetle feeds and develops exclusively on the the inner-wood of deciduous trees. A fungus within its gut alters lignin and makes it easier to break down wood. Credit: Joshua Peter Kaffer.

References:

Penn State University: Novel fungus helps beetles to digest hard wood - August 19, 2008.

Article continues

posted by Biopact team at 6:34 PM 0 comments links to this post