Alstom, EPRI, We Energies to pilot chilled ammonia process to capture CO2

The first pilot project that uses chilled ammonia to capture carbon dioxide (CO2) from coal-fueled power plants is expected to commence operation this week, according to an announcement from Alstom, the Electric Power Research Institute (EPRI) and We Energies. Biopact tracks developments in carbon capture and storage (CCS) technologyies, because they can be applied to biomass fuels, in which case radical "negative emissions" can be obtained.

The first pilot project that uses chilled ammonia to capture carbon dioxide (CO2) from coal-fueled power plants is expected to commence operation this week, according to an announcement from Alstom, the Electric Power Research Institute (EPRI) and We Energies. Biopact tracks developments in carbon capture and storage (CCS) technologyies, because they can be applied to biomass fuels, in which case radical "negative emissions" can be obtained.The chilled ammonia process developed by Alstom is one of several options to capture CO2. Three basic approaches exist: capturing the greenhouse gas before the fuel is combusted (pre-combustion capture), during it being burned in a stream of oxygen (oxyfuel combustion) or after combustion, when the CO2 is separated from the flue gas (post-combustion capture) (schematic, click to enlarge).

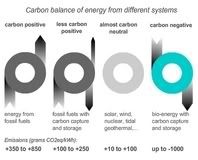

When either of these technologies are applied to power plants that burn renewable biofuels, the most radical tool in the climate fight emerges: cabon-negative energy. Renewable biomass captures CO2 from the atmosphere; if the CO2 released during the combustion of the fuel is not captured, and returned to the atmosphere, the classic "carbon neutral" cycle so typical of renewables is the result. But when the CO2 is instead captured and stored, "negative emissions" can be obtained. That is: energy which actively removes CO2 from the atmosphere.

When either of these technologies are applied to power plants that burn renewable biofuels, the most radical tool in the climate fight emerges: cabon-negative energy. Renewable biomass captures CO2 from the atmosphere; if the CO2 released during the combustion of the fuel is not captured, and returned to the atmosphere, the classic "carbon neutral" cycle so typical of renewables is the result. But when the CO2 is instead captured and stored, "negative emissions" can be obtained. That is: energy which actively removes CO2 from the atmosphere. Only bioenergy based energy systems are capable of generating negative emissions. The difference between bio-energy with carbon storage and other renewables is therefor radical: whereas wind, solar or hydropower are slightly carbon-positive over their lifecycle - adding around 20 to 100 tons of CO2eq per GWh of electricity generated - bio-energy with carbon storage can remove up to 1000 tons from the atmosphere. As such, according to scientists from the Abrupt Climate Change Strategy group, these systems can reverse climate change by mid-century if implemented on a wide enough scale.

Alstom, which has been retrofitting and transforming coal-fired power plants to co-fire or solely burn biomass, has recently begun to refer to these carbon-negative bioenergy systems (e.g. in this presentation), an indication that the concept's revolutionary potential is gradually being recognized (many other of the key players have hinted at negative emissions systems; Aker Kvaerner already has a dedicated capture technology for biomass, called Just Catch Bio - more here and here). Add that in the medium to longer term, biomass is expected by the European Commission to become cheaper than coal, and the prospect of negative emissions energy becomes highly likely.

The chilled ammonia system uses a CO2 absorber similar to SO2 absorbers and is designed to operate with slurry. The cooled flue gas flows upwards in counter current to the slurry containing a mix of dissolved and suspended ammonium carbonate and ammonium bicarbonate. More than 90% of the CO2 from the flue gas is captured in the absorber. The remaining low concentration of ammonia in the clean flue gas is captured by cold-water wash and returned to the absorber. The clean flue gas, which now contains mainly nitrogen, excess oxygen and low concentration of CO2, flows to the stack (schematic, click to enlarge).

The chilled ammonia system uses a CO2 absorber similar to SO2 absorbers and is designed to operate with slurry. The cooled flue gas flows upwards in counter current to the slurry containing a mix of dissolved and suspended ammonium carbonate and ammonium bicarbonate. More than 90% of the CO2 from the flue gas is captured in the absorber. The remaining low concentration of ammonia in the clean flue gas is captured by cold-water wash and returned to the absorber. The clean flue gas, which now contains mainly nitrogen, excess oxygen and low concentration of CO2, flows to the stack (schematic, click to enlarge).The chilled ammonia process is one of the more promising post-combustion capture technologies because it can be fitted to existing power plants, both biomass, coal and natural gas combined cycle facilities.

Alstom designed, constructed and will now operate its 1.7-megawatt pilot system that captures CO2 from a portion of coal-fired boiler flue gas at We Energies’ Pleasant Prairie Power Plant, a 1,210-megawatt coal-fired generating station. The trial should begin operations the first week of March:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture :: chilled ammonia :: bio-energy with carbon capture :: carbon-negative :: negative emissions :: climate change ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture :: chilled ammonia :: bio-energy with carbon capture :: carbon-negative :: negative emissions :: climate change :: In laboratory testing it has demonstrated the potential to capture more than 90 percent of CO2 at a cost that is far less than other carbon capture technologies. Once captured, the CO2 can be used commercially or sequestered in suitable underground geologic sites.

This pilot is a significant milestone in our ongoing partnership with We Energies and EPRI. We Energies' operational expertise and EPRI's financial and research collaboration support are perfect complements to Alstom's leadership in CO2 capture research and development. This plant will provide invaluable information in leading to commercialization of CO2 capture technology. - Jean-Michel Aubertin, Senior Vice President of Alstom's Energy and Environment Systems GroupThe demonstration project will provide the opportunity to test the process on a larger scale and to evaluate its potential to remove CO2 while reducing the energy used in the process.

EPRI will conduct an engineering and environmental performance and cost analysis during the project, which will last at least one year. Through EPRI’s collaborative research and development program, more than 30 organizations representing a large portion of the coal-fueled utilities in the United States have committed to support this project. EPRI will conduct an extensive evaluation of the system’s performance and support the development of technological and economic analyses associated with applying the carbon-capture process on a commercial scale, primarily to larger coal-fueled power plants.

Alstom is a global leader in the world of power generation and rail infrastructure and sets the benchmark for innovative and environmentally friendly technologies. Alstom builds the fastest train and the highest capacity automated metro in the world, and provides turnkey integrated power plant solutions and associated services for a wide variety of energy sources, including hydro, gas, coal and wind. About 25 percent of the world’s electricity produced is generated by Alstom technology. The Group employs 65,000 people in 70 countries, and had orders of euro 19 billion in 2006-07. The Pleasant Prairie facility is one of six ALSTOM pilot projects already under way in Germany, the U.S., Norway, Sweden and France. Other projects are being studied and will be announced later this year.

We Energies serves more than 1.1 million electric customers in Wisconsin and Michigan’s Upper Peninsula and more than 1 million natural gas customers in Wisconsin. Our energy prices are approximately 10 percent below the average for major U.S. cities. We Energies is the trade name of Wisconsin Electric Power Company and Wisconsin Gas LLC, the principal utility subsidiaries of Wisconsin Energy Corporation.

The Electric Power Research Institute (EPRI, ) conducts research and development on technology, operations and the environment for the global electric power sector. EPRI is an independent nonprofit organization. EPRI brings together members, the institute’s scientists and engineers, along with other stakeholders to meet the challenges facing the electric sector. EPRI supports multi-disciplined research. EPRI's members represent more than 90 percent of the electricity generated in the United States, and international participation includes 40 countries. EPRI has major offices and laboratories in Palo Alto, Calif.; Charlotte, N.C.; Knoxville, Tenn., and Lenox, Mass.

References:

Alstom: Alstom together with its US partners EPRI and We Energies launches innovative project to capture CO2 using chilled ammonia - February 28, 2008.

Alstom: Clean Power Today: Pathways for utilization of fossil fuels in a low carbon world – Power Generation [*.pdf], October 2007.

H. Audus and P. Freund, "Climate Change Mitigation by Biomass Gasificiation Combined with CO2 Capture and Storage", IEA Greenhouse Gas R&D Programme.

James S. Rhodesa and David W. Keithb, "Engineering economic analysis of biomass IGCC with carbon capture and storage", Biomass and Bioenergy, Volume 29, Issue 6, December 2005, Pages 440-450.

Noim Uddin and Leonardo Barreto, "Biomass-fired cogeneration systems with CO2 capture and storage", Renewable Energy, Volume 32, Issue 6, May 2007, Pages 1006-1019, doi:10.1016/j.renene.2006.04.009

Christian Azar, Kristian Lindgren, Eric Larson and Kenneth Möllersten, "Carbon Capture and Storage From Fossil Fuels and Biomass – Costs and Potential Role in Stabilizing the Atmosphere", Climatic Change, Volume 74, Numbers 1-3 / January, 2006, DOI 10.1007/s10584-005-3484-7

Peter Read and Jonathan Lermit, "Bio-Energy with Carbon Storage (BECS): a Sequential Decision Approach to the threat of Abrupt Climate Change", Energy, Volume 30, Issue 14, November 2005, Pages 2654-2671.

Stefan Grönkvist, Kenneth Möllersten, Kim Pingoud, "Equal Opportunity for Biomass in Greenhouse Gas Accounting of CO2 Capture and Storage: A Step Towards More Cost-Effective Climate Change Mitigation Regimes", Mitigation and Adaptation Strategies for Global Change, Volume 11, Numbers 5-6 / September, 2006, DOI 10.1007/s11027-006-9034-9

Article continues

--------------

--------------

A 7.1MW biomass power plant to be built on the Haiwaiian island of Kaua‘i has received approval from the local Planning Commission. The plant, owned and operated by Green Energy Hawaii, will use albizia trees, a hardy species that grows in poor soil on rainfall alone. The renewable power plant will meet 10 percent of the island's energy needs.

A 7.1MW biomass power plant to be built on the Haiwaiian island of Kaua‘i has received approval from the local Planning Commission. The plant, owned and operated by Green Energy Hawaii, will use albizia trees, a hardy species that grows in poor soil on rainfall alone. The renewable power plant will meet 10 percent of the island's energy needs.

Saturday, March 01, 2008

Westward Expansion in 19th century America mainly caused by low transportation costs, population growth

Applying quantitative analysis to historical explanations, a new study by economist Guillaume Vandenbroucke of the University of Southern California now finds that the price of land was significantly less important to Westward Expansion than population growth and technological innovation leading to a revolution in low cost transportation. This revolution allowed people and goods to be transported Westwards with ease.

Vandenbroucke's findings [*.pdf], appearing in the current issue of International Economic Review, have important implications for how to understand current population patterns (rural - urban migration to the emerging megacities) and international immigration to the United States. By extension, the data show the importance of land use changes, low cost transportation and (physical and social) mobility to the emergence of Modernity. It is tempting to read Vandenbroucke's findings through the spectrum of current record energy prices, international migration, population growth and land resources in the rapidly modernising developing world.

The economist describes the key aspects of America's great transformation as follows:

To examine what forces were most directly responsible for the magnitude of this movement and land accumulation, Vandenbroucke takes into account such factors as the amount of land available in the Eastern United States, wage and productivity growth in the East, improvements in technologies to transform "wild land" into arable and habitable land (clearing of forests and grasslands, fencing, etc.), and the expansion and improvement of transportation infrastructures:

To account for the range of variables and possible factors, Vandenbroucke determined a model in which each factor was held at a constant level while the others shifted at historical rates.

Surprisingly, Vandenbroucke found that changes in productivity in the East had little effect on the Westward Expansion, relative to population growth and a decrease in transportation costs. Rising wages and productivity makes it easier to move, but it also makes it less pressing to move.

Instead, he finds that population growth and technological innovation worked in concert as the main driving factors of Western Expansion. Specifically, the decrease in transportation costs induced Western migration and the redistribution of the American population - without it only 30 percent of the population would have been in the West in 1900, compared to an actual historical figure of 60 percent.

Land improvement technologies such as the use of barbed wire to cut down on the time needed to build a fence, or improved techniques to clear forests and grasslands had a small effect on the accumulation of land in the West.

Picture: The First Transcontinental Railroad in the United States was built across North America in the 1860s, linking the railway network of the Eastern United States with California on the Pacific coast. Ceremonially completed on May 10, 1869, at the famous "golden spike" event at Promontory Summit, Utah, it created a nation-wide mechanized transportation network that revolutionized the population and economy of the American West. Credit: Wikimedia.

References:

Vandenbroucke, G. "The U.S. Westward Expansion", International Economic Review, Vol. 49, No. 1, February 2008.

Vandenbroucke, G. "The American Frontier: Technology versus Immigration", Review of Economic Dynamics, forthcoming.

Eurekalert: What caused westward expansion in the United States? - February 28, 2008.

Article continues

posted by Biopact team at 7:01 PM 0 comments links to this post