Researchers: hybrid vehicles slow transition to more sustainable cars

Hybrid electric vehicles that run on both conventional gasoline and stored electricity can be no more than a stop gap until more sustainable technology is developed, according to researchers in France. Writing in the Inderscience publication International Journal of Automotive Technology and Management, they suggest that the adoption of HEVs might even slow development of more sustainable fuel-cell powered electric vehicles that utilize (bio)hydrogen as their fuel.

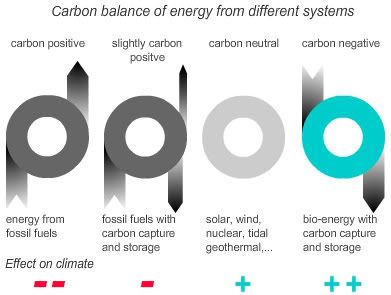

No matter which type of vehicle might be most sustainable in the future - pure electric or hydrogen powered -, one thing is certain: in both cases biomass remains a very good candidate to generate the energy needed for transportation in an affordable, clean and efficient manner - be it H2 or electricity (see below). Biomass energy can even yield radical "negative emissions" when it is coupled to carbon capture and storage, and thus actively remove CO2 from the past from the atmosphere - something only biomass is capable of.

Jean-Jacques Chanaron, Research Director within the French National Centre for Scientific Research (CNRS) and Chief Scientific Advisor at the Grenoble School of Management and Julius Teske at Grenoble, question strongly whether the current acceptance of hybrid vehicle technology particularly in the USA is in any way environmentally sustainable.

The researchers have analyzed the spread of this technology including the non-financial drivers for its adoption. They point out that most manufacturers are rapidly integrating hybrid electric vehicles into their technology portfolio, despite the absence of significant profitability.

They add that the misinformed craze for hybrid vehicles especially in the USA, and increasingly in Japan and Europe, and potentially in China, could represent a red light for more innovative technologies, such as viable fuel-cell cars that can use sustainably sourced fuels, such as hydrogen. They concur with earlier studies that suggest that hydrogen fuel cells will not be marketable in high volumes before at least 2025. This could, however, be too late for some models of climate change and emissions reduction. They also point out that even fuel cell technology has its drawbacks and much of the marketing surrounding its potential has emerged only from the hydrogen lobby itself.

Moreover, political pressures also play a significant part. The three major US manufacturers - GM, Ford, and Chrysler - recently urged President Bush to financially and politically support a national technological solution for hybrids; this was independent of the currently dominant solutions initiated by Toyota. The researchers concede that "the quest for low emission, clean, and high-mileage vehicles is on its way and should be at the top of the manufacturers' agenda". However, they suggest that the technology, marketing, and public perception leads to one overriding problem: is a hybrid strategy sustainable in the long run? Chanaron and Teske think not:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: bio-electricity :: renewable :: mobility :: hybrid electric vehicle :: fuel cell :: electric vehicle ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: bio-electricity :: renewable :: mobility :: hybrid electric vehicle :: fuel cell :: electric vehicle ::

The complexity and high cost of the hybrid technology is also playing against itself, they say: "There is a huge strategic dilemma for the key players of the automotive industry where a mistake in technology decision-making might turn even a big player into a take-over candidate. The next five years will provide industry observers with more accurate trends and success or failure factors."

Biopact notes that no matter which vehicle technology is most sustainable over the long run, bioenergy is in all cases the most economically viable, and in many cases the most environmentally friendly way to produce automotive energy.

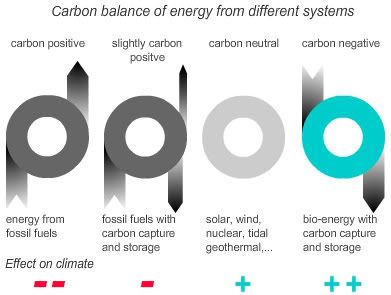

When hydrogen is chosen as the fuel for fuel cell cars, the cleanest, most efficient and most affordable way to produce the gas is by converting biomass through gasification. This is the conclusion of a very large EU-funded well-to-wheel study of over 70 different propulsion technologies and energy pathways for the future. Of more than 30 different H2 production pathways - from electrolysis on the the basis of nuclear or wind power to steam reforming of natural gas - biohydrogen used in fuel cells and made from the gasification of biomass, is the cleanest and gives most mileage per amount of energy invested (previous post; graph, click to enlarge).

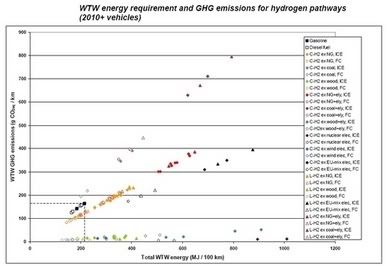

When pure electric cars are to be the future, then again bio-electricity is the clear winner amongst all sources of energy, over the medium to long term. According to the recent EU Strategic Energy Technology Plan, biomass based electricity is expected to become the cheapest form of electricity - even beating coal (previous post; table, click to enlarge).

Moreover, both biomass and biohydrogen production allow for the implementation of radical carbon-negative energy concepts. Bio-electricity and biohydrogen can be completely decarbonised by coupling their production to carbon capture and storage (CCS). When this is done, an energy carrier yielding "negative emissions" is obtained. Only fuels and energy carriers made from biomass can become carbon-negative, all other renewables remain fundamentally carbon positive.

The difference is staggering: over their lifecycle, renewables like wind or solar contribute between +30 and +100 gCO2eq per kWh of electricity. Bioenergy coupled to CCS yields up to -1000 gCO2 per kWh (that is: minus, "negative" emissions).

The bizarre aspect of such radical forms of carbon-negative bioenergy is that the more you use of it (in this case in your electric or hydrogen car), the more CO2 you take out of the atmosphere. The more you drive, the more you save the planet (previous post). Clearly, when it comes to mitigating climate change, carbon-negative biomass based transportation energy is the way forward.

The only issue with biomass is the fact that it is such a versatile primary energy resource. It can be transformed into a large range of products - from bioproducts and green platform chemicals to liquid, gaseous or solid biofuels - and used in a variety of applications - from producing heat to acting as a carbon sink - that it remains to be seen which utilization pathway is most efficient. Transforming biomass into an energy carrier for future cars might not be the most optimal use, because other services and products might be more cost-effective, better at mitigating climate change, or more energy efficient.

References:

Jean-Jacques Chanaron and Julius Teske, "Hybrid vehicles: a temporary step", International Journal of Automotive Technology and Management, 2007 - Vol. 7, No.4 pp. 268 - 288, DOI: 10.1504/IJATM.2007.017061

Eurekalert: The trouble with hybrids - Hybrid electric vehicles not as green as they are painted - February 7, 2008.

Biopact: The strange world of carbon-negative bioenergy: the more you drive your car, the more you tackle climate change - October 29, 2007

Biopact: Commission presents European Strategic Energy Technology Plan: towards a low carbon future - November 23, 2007

Biopact: Hydrogen out, compressed biogas in - October 01, 2006

Article continues

No matter which type of vehicle might be most sustainable in the future - pure electric or hydrogen powered -, one thing is certain: in both cases biomass remains a very good candidate to generate the energy needed for transportation in an affordable, clean and efficient manner - be it H2 or electricity (see below). Biomass energy can even yield radical "negative emissions" when it is coupled to carbon capture and storage, and thus actively remove CO2 from the past from the atmosphere - something only biomass is capable of.

Jean-Jacques Chanaron, Research Director within the French National Centre for Scientific Research (CNRS) and Chief Scientific Advisor at the Grenoble School of Management and Julius Teske at Grenoble, question strongly whether the current acceptance of hybrid vehicle technology particularly in the USA is in any way environmentally sustainable.

The researchers have analyzed the spread of this technology including the non-financial drivers for its adoption. They point out that most manufacturers are rapidly integrating hybrid electric vehicles into their technology portfolio, despite the absence of significant profitability.

They add that the misinformed craze for hybrid vehicles especially in the USA, and increasingly in Japan and Europe, and potentially in China, could represent a red light for more innovative technologies, such as viable fuel-cell cars that can use sustainably sourced fuels, such as hydrogen. They concur with earlier studies that suggest that hydrogen fuel cells will not be marketable in high volumes before at least 2025. This could, however, be too late for some models of climate change and emissions reduction. They also point out that even fuel cell technology has its drawbacks and much of the marketing surrounding its potential has emerged only from the hydrogen lobby itself.

There is a general convergence of strategies towards promoting hybrid vehicles as the mid-term solution to very low-emission and high-mileage vehicles. This is largely due to Toyota's strategy of learning the technology, while building up its own "quasi-standard", thanks to its high-quality and reliability reputation and its high market share on the North American market. - Jean-Jacques Chanaron & Julius TeskeBut they say that such a convergence is based more on customer perception triggered by very clever marketing and communication campaigns than on pure rational scientific arguments and may result in the need for any manufacturer operating in the USA to have a hybrid electric vehicle in its model range in order to survive.

Moreover, political pressures also play a significant part. The three major US manufacturers - GM, Ford, and Chrysler - recently urged President Bush to financially and politically support a national technological solution for hybrids; this was independent of the currently dominant solutions initiated by Toyota. The researchers concede that "the quest for low emission, clean, and high-mileage vehicles is on its way and should be at the top of the manufacturers' agenda". However, they suggest that the technology, marketing, and public perception leads to one overriding problem: is a hybrid strategy sustainable in the long run? Chanaron and Teske think not:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: bio-electricity :: renewable :: mobility :: hybrid electric vehicle :: fuel cell :: electric vehicle ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biohydrogen :: bio-electricity :: renewable :: mobility :: hybrid electric vehicle :: fuel cell :: electric vehicle :: The complexity and high cost of the hybrid technology is also playing against itself, they say: "There is a huge strategic dilemma for the key players of the automotive industry where a mistake in technology decision-making might turn even a big player into a take-over candidate. The next five years will provide industry observers with more accurate trends and success or failure factors."

Biopact notes that no matter which vehicle technology is most sustainable over the long run, bioenergy is in all cases the most economically viable, and in many cases the most environmentally friendly way to produce automotive energy.

When hydrogen is chosen as the fuel for fuel cell cars, the cleanest, most efficient and most affordable way to produce the gas is by converting biomass through gasification. This is the conclusion of a very large EU-funded well-to-wheel study of over 70 different propulsion technologies and energy pathways for the future. Of more than 30 different H2 production pathways - from electrolysis on the the basis of nuclear or wind power to steam reforming of natural gas - biohydrogen used in fuel cells and made from the gasification of biomass, is the cleanest and gives most mileage per amount of energy invested (previous post; graph, click to enlarge).

When pure electric cars are to be the future, then again bio-electricity is the clear winner amongst all sources of energy, over the medium to long term. According to the recent EU Strategic Energy Technology Plan, biomass based electricity is expected to become the cheapest form of electricity - even beating coal (previous post; table, click to enlarge).

The difference is staggering: over their lifecycle, renewables like wind or solar contribute between +30 and +100 gCO2eq per kWh of electricity. Bioenergy coupled to CCS yields up to -1000 gCO2 per kWh (that is: minus, "negative" emissions).

The bizarre aspect of such radical forms of carbon-negative bioenergy is that the more you use of it (in this case in your electric or hydrogen car), the more CO2 you take out of the atmosphere. The more you drive, the more you save the planet (previous post). Clearly, when it comes to mitigating climate change, carbon-negative biomass based transportation energy is the way forward.

The only issue with biomass is the fact that it is such a versatile primary energy resource. It can be transformed into a large range of products - from bioproducts and green platform chemicals to liquid, gaseous or solid biofuels - and used in a variety of applications - from producing heat to acting as a carbon sink - that it remains to be seen which utilization pathway is most efficient. Transforming biomass into an energy carrier for future cars might not be the most optimal use, because other services and products might be more cost-effective, better at mitigating climate change, or more energy efficient.

References:

Jean-Jacques Chanaron and Julius Teske, "Hybrid vehicles: a temporary step", International Journal of Automotive Technology and Management, 2007 - Vol. 7, No.4 pp. 268 - 288, DOI: 10.1504/IJATM.2007.017061

Eurekalert: The trouble with hybrids - Hybrid electric vehicles not as green as they are painted - February 7, 2008.

Biopact: The strange world of carbon-negative bioenergy: the more you drive your car, the more you tackle climate change - October 29, 2007

Biopact: Commission presents European Strategic Energy Technology Plan: towards a low carbon future - November 23, 2007

Biopact: Hydrogen out, compressed biogas in - October 01, 2006

Article continues

--------------

--------------

Austrian bioenergy group Cycleenergy acquired controlling interest in Greenpower Projektentwicklungs GmbH, expanding its biomass operational portfolio by 16 MW to a total of 22 MW. In the transaction Cycleenergy took over 51% of the company and thereby formed a joint venture with Porr Infrastruktur GmbH, a subsidiary of Austrian construction company Porr AG. Greenpower operates two wood chip CHP facilities in Upper and Lower Austria, each with an electric capacity of 2 MW. The plants have been in operation since the middle of last year and consume more than 30,000 tonnes of wood chips and are expected to generate over €5 million in additional revenue.

Austrian bioenergy group Cycleenergy acquired controlling interest in Greenpower Projektentwicklungs GmbH, expanding its biomass operational portfolio by 16 MW to a total of 22 MW. In the transaction Cycleenergy took over 51% of the company and thereby formed a joint venture with Porr Infrastruktur GmbH, a subsidiary of Austrian construction company Porr AG. Greenpower operates two wood chip CHP facilities in Upper and Lower Austria, each with an electric capacity of 2 MW. The plants have been in operation since the middle of last year and consume more than 30,000 tonnes of wood chips and are expected to generate over €5 million in additional revenue.

A type of bacteria that helps termites digest wood could be key to making ethanol cheaply from non-food crops such as wood and grass.

A type of bacteria that helps termites digest wood could be key to making ethanol cheaply from non-food crops such as wood and grass.

Scientists at South Dakota State University's

Scientists at South Dakota State University's

Thursday, February 07, 2008

Researchers develop highly efficient hybrid nanoporous membrane to dehydrate biofuels; could replace distillation process

After testing during 18 months, the new 100 nanometer thick membranes, embedded in a cylinder (schematic, click to enlarge), prove to be highly effective, while having continuously been exposed to a temperature of 150 ºC. Existing ceramic and polymer membranes will last considerably shorter periods of time, when exposed to the combination of water and high temperatures. The scientists managed to do this using a new ‘hybrid’ type of material combining the best of both worlds of polymer and ceramic membranes. The result is a membrane with pores sufficiently small to let only the smallest molecules pass through.

Ceramic membranes, made of silica, degrade because they react with water and steam. In the new membrane, part of the ceramic links is therefore replaced by organic links. By doing this, water doesn’t have the chance to ‘attack’ the membranes. Manufacturing the new hybrid membranes is simpler than that of ceramic membranes, because the material is flexible and will not show cracks. What they have in common with ceramic membranes is the rapid flow: an advantage of this is that the membrane surface can be kept small:

The hybrid membranes are suitable for ‘drying’ solvents and biofuels, an application for which there is a large potential market worldwide. The main advantage of membrane technology is that it consumes far less energy than common distillation techniques. The scientists also foresee opportunities in separating hydrogen gas from gas mixtures. This implies a broad range of applications in sustainable energy. Apart from that, the hybrid membranes are suitable for desalinating water. Using a hybrid membrane that is much smaller than the current polymer membranes, the same result can be achieved

The results have been achieved in a close cooperation of scientists from the Inorganic Materials Science Group of the MESA+ Institute for Nanotechnology (UT), the Energy Efficiency in Industry department of ECN and the University of Amsterdam. The invention has been patented worldwide.

Schematic: the cylinder is the carrier of a hybrid membrane: a layer of about 100 nanometer thickness. The insert shows a close-up of the layer showing the organic links and pores. From the left of the tube, only water molecules leave the sieve. Credit: University of Twente.

References:

Hessel Castricum, Ashima Sah, Robert Kreiter, Dave Blank, Jaap Vente and André ten Elshof, "‘Hybrid ceramic nanosieves: stabilizing nanopores with organic links", Chemical Communications, 2008, DOI: 10.1039/b718082a

University of Twente: Nanosieve saves energy in biofuel production - February 7, 2008.

Article continues

posted by Biopact team at 8:33 PM 0 comments links to this post