World's most efficient CHP station uses biomass: a look at Denmark's Avedore 2 multi-fuel plant

In September 1994, Denmark's Energy Agency approved plans for the construction of a highly efficient combined heat and power (CHP) plant, to be built by Energi E2 and Vattenfall. The 570MW Avedore 2 plant, situated on the coast just south of Copenhagen, was approved on the condition that its owner, SK Power, decommission three older coal-fired power plants to reduce net emissions of CO2 (10%), NOx (20%) and SO2 (30%). Avedore 2 was unique in its design because it was conceived as a multi-fuel plant from the start, capable of using natural gas, coal and biomass. In 1996, Denmark's government banned the use of coal. And so Avedore proved to be a safe bet, by switching entirely to biomass and gas. Today, renewable biomass is the plant's main fuel.

In September 1994, Denmark's Energy Agency approved plans for the construction of a highly efficient combined heat and power (CHP) plant, to be built by Energi E2 and Vattenfall. The 570MW Avedore 2 plant, situated on the coast just south of Copenhagen, was approved on the condition that its owner, SK Power, decommission three older coal-fired power plants to reduce net emissions of CO2 (10%), NOx (20%) and SO2 (30%). Avedore 2 was unique in its design because it was conceived as a multi-fuel plant from the start, capable of using natural gas, coal and biomass. In 1996, Denmark's government banned the use of coal. And so Avedore proved to be a safe bet, by switching entirely to biomass and gas. Today, renewable biomass is the plant's main fuel.Flexibility and efficiency

The switch was helped by a spike in natural gas prices in the late 1990s. Originally, gas was expected to contribute 85% of Avedore 2's total fuel consumption in the main boiler. Rocketing gas prices favored biofuels, so in early 2001 biomass was decided upon for the main fuel source.

Avedore 2, inaugurated in 2002, made the green switch successfully and is now a set of superlatives: it is the world's largest biomass power plant as well as the cleanest and most efficient cogeneration power station. It meets the heating demands of 200,000 households and supplies electricity to over 1.3 million homes (Denmark has a population of 5.47 million). The green plant covers more than 20% of Eastern Denmark's needs - the most densely populated region of the country - and supplies 570MW of heat to Greater Copenhagen's district heating system. The combined heat and power efficiency comes in at a whopping 95%.

Today the impressive Avedore 2 station is owned by Dong Energy, Denmark's largest energy company, partly state owned and the result of a merger between Dong, Elsam, Energi E2, Nesa and the electrical departments of two major utilities.

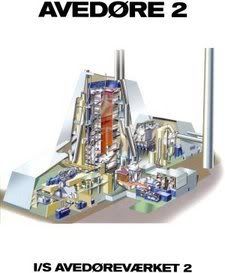

The 44MWe biomass plant provides the baseload for the power station, while two 55MWe gas turbines work as a peak load facility, which means they are started up when there is additional demand for electricity - usually in the mornings and evenings. The 'heart' of the power station is the USC (Ultra Super Critical) facility which comprises a boiler, steam turbine, generator and flue gas cleaning plant (see cutaway, click to enlarge).

The 44MWe biomass plant provides the baseload for the power station, while two 55MWe gas turbines work as a peak load facility, which means they are started up when there is additional demand for electricity - usually in the mornings and evenings. The 'heart' of the power station is the USC (Ultra Super Critical) facility which comprises a boiler, steam turbine, generator and flue gas cleaning plant (see cutaway, click to enlarge).By increasing steam pressure and temperature to exceptionally high levels it ensures very efficient fuel use. This means Avedore 2 uses less fuel to generate one kilowatt-hour than older generators. It uses about 50% of the energy in the fuel to generate electricity compared with only 35% fuel utilisation in older units. Connecting all the systems together creates a synergy that means the total output is greater than all the individual parts. This is what makes the facility the most flexible and energy efficient CHP plant of its kind in the world.

Biomass supplies

The key to Avedore 2's clean power generation is its reliance on renewable biomass as a fuel. The high volumes of biofuels consumed helps the state owned energy company to comply with the Danish Parliament's Biomass Action Plan. This set a target of 1.2 million tonnes of straw and 0.2 million tonnes of wood chips to be burned annually. Half of the target must be met by eastern Denmark, and Avedore 2 alone accounts for more than a quarter. The Biomass Action Plan, approved already in 1993, puts the country on track to meet its EU obligations which call, in Denmark's case, for 30% of renewable energy by 2020. Denmark today already generates 17% of all its energy from renewables, making it one of the EU's green energy leaders. Avedore 2 significantly contributes to this achievement.

The key to Avedore 2's clean power generation is its reliance on renewable biomass as a fuel. The high volumes of biofuels consumed helps the state owned energy company to comply with the Danish Parliament's Biomass Action Plan. This set a target of 1.2 million tonnes of straw and 0.2 million tonnes of wood chips to be burned annually. Half of the target must be met by eastern Denmark, and Avedore 2 alone accounts for more than a quarter. The Biomass Action Plan, approved already in 1993, puts the country on track to meet its EU obligations which call, in Denmark's case, for 30% of renewable energy by 2020. Denmark today already generates 17% of all its energy from renewables, making it one of the EU's green energy leaders. Avedore 2 significantly contributes to this achievement.The biofuel at Avedore 2 comes in the form of straw bales and pellets, each contributing around half of the total amount of biomass burned in the station. Last year, Avedore 2 consumed 172,000 tonnes of straw bales, including hay from rape, cereals and ryegrass from 500 different farms in eastern Denmark. Every day, Avedore 2 handles 65 lorry-loads of 24 bales. Currently these loads weigh about 12 tonnes, but with the increased density from a new generation of efficient balers the payload is expected to increase by at least 20 percent, further improving the efficiency of the operation:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: straw :: efficiency :: CHP :: emissions :: renewables :: Denmark ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: straw :: efficiency :: CHP :: emissions :: renewables :: Denmark :: The straw-fired biomass facility consists of a boiler, straw store, ash separator and a system for handling the bottom and fly ash. The straw store holds enough bales to run the plant for two to three days, with deliveries arriving from Monday until noon on Saturday, every week.

The whole biomass side of the plant - cranes, straw lines and feeding system - is designed exclusively to handle bale dimensions of 1.2m x 1.2m x 2.5m. According to Pernille Harder Andersen, information officer at the plant, the higher density and heavier packages made by the latest balers will be of great benefit to the operations, helping to further improve efficiency - simply because the straw lines will be able to handle more material. The bale size choice also reflects years of experience from farmers and contractors baling straw for industrial and other uses.

The plant will accept bales with moisture contents up to 24 percent and farms are expected to store them under cover until they are required. Bales are then transported to Avedore 2 on lorries stacked with 24 bales laid across the bed in two layers. On arrival, the trucks are unsheeted on a special gantry. Then the truck moves to the unloading area where the bales are weighed and ultra-sonic sensors are used to check the moisture content.

If the moisture content is within the parameters, the operator, sitting high up in a control room, uses an over-head crane to lift off each layer of 12 bales in one go. He then stacks the bales in the storage area in a particular pattern, which is critical because from now on all the handling is carried out automatically.

Two special straw 'tables' feed the bales onto four straw lines that convey the MF 'Hesston' bales into the process. First job is to remove the strings, which are cut and stripped off before the bale feeds into contra-rotating peg rollers that loosen the material before it is blown into the boiler.

According to Harder Andersen, it is actually very difficult to combust straw because its silicates are very corrosive. So it took quite a while to perfect the system and get it running as efficiently as it does today. The steam generated by the biomass boiler is directed to the central turbine, which makes much better use of the energy in the fuel compared with using a separate steam turbine.

Dong Energy is Denmark’s largest power generator, 73 percent state owned. The company produces more than 50% of Denmark’s power and approximately 40% of the district heating. It is also deeply involved in leading European liquid biofuel research, focusing on the utilization of biomass for the cogeneration of power, heat and liquid fuels (previous post).

References:

EU: Denmark renewable energy country file, at Energy.eu.

ELSAM: Biomass to Power in Danish Power Plants [*.pdf].

Power Technology: Avedore multi-fuel power plant, Denmark.

Independent: MF fuels largest biomass boiler - February 5, 2008.

Article continues

--------------

--------------

The 2008 edition of Bioenergy World Europe will take place in Verona, Italy, from 7 to 10 February. Gathering a broad range of international exhibitors covering gaseous, liquid and solid bioenergy, the event aims to offer participants the possibility of developing their business through meetings with professionals, thematic study tours and an international forum focusing on market and regulatory issues, as well as industry expertise.

The 2008 edition of Bioenergy World Europe will take place in Verona, Italy, from 7 to 10 February. Gathering a broad range of international exhibitors covering gaseous, liquid and solid bioenergy, the event aims to offer participants the possibility of developing their business through meetings with professionals, thematic study tours and an international forum focusing on market and regulatory issues, as well as industry expertise.

The state-owned Brazilian Agricultural Research Enterprise (

The state-owned Brazilian Agricultural Research Enterprise (

Tuesday, February 05, 2008

WMO mobilizes global efforts in climate prediction

WMO opened the first meeting of the International Organizing Committee of the World Climate Conference-3 (WCC-3) which convenes in Geneva in 2009. More than 20 organizations, including United Nations agencies, are participating in the three-day meeting to prepare for the milestone 2009 conference, with the theme: “Climate prediction for decision-making: focusing on seasonal to inter-annual time-scales taking into account multi-decadal prediction.”

The need for climate forecasts has been growing with the increased recognition of society’s vulnerability to climate variability and change. Climate prediction centres around the world currently produce global temperature and rain forecasts through use of powerful computer models.

But there is recognition that strengthening and coordinating these capabilities could optimize the global response to climate variability and change, and meet the needs of decision-makers for better climate predictions in major socio-economic sectors.

WMO, with its 188 Members covering the globe and as a lead sponsor of the World Climate Research Programme, has the experience and strength to facilitate a mechanism to bring under one umbrella the climate forecast centres around the world. With their pooled expertise, the world will be better able to respond to global challenges created by climate variability and change, the WMO says:

The ongoing meeting is working to prepare an agenda for a science and ministerial segment of the 2009 conference. WCC-3 aims to promote disaster risk reduction and better use of climate prediction for decision-making, thus making a major contribution to sustainable development. It also aims to bridge the gap between scientists and end-users of climate prediction data.

Historically, World Climate Conferences have been decisive events. The first, held in 1979, led to the establishment of the Nobel Peace Prize-winning Intergovernmental Panel on Climate Change in 1988. The second conference, in 1990, strengthened global efforts that resulted in the creation of the United Nations Framework Convention on Climate Change in 1992.

WMO is the United Nations' authoritative voice on weather, climate and water.

References:

WMO: WMO Launches Drive to Mobilize Global Efforts in Climate Prediction - February 4, 2008.

WMO: World Climate Conference-3 2009 - Climate prediction for decision-making: focusing on seasonal to interannual time-scales.

Article continues

posted by Biopact team at 9:46 PM 0 comments links to this post