How to turn coal plants into climate-solution machines

Climate blogger Joseph Romm spoke with an expert on solar thermal energy, who pointed out that two utilities have just announced they will test the use of solar thermal to add steam into the steam cycle of natural gas plants. The trials will happen under the auspices of the Electric Power Research Institute (EPRI). But EPRI plans to “add solar thermal technology to coal-powered plants as well.” Why?

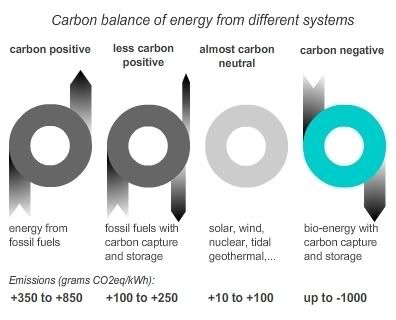

In addition to reducing costs and greenhouse gas emissions, EPRI believes that solar thermal technology could also boost coal and natural gas power enough in existing plants to eliminate the need for new infrastructure.Romm goes on to note that this combination is not quite as cost-effective yet as biomass co-firing, but if it proves to be viable commercially, we can begin to think of coal plants as basic infrastructures that can be transformed into ever cleaner power plants. The end-goal would be power plants that generate carbon-negative energy, that is, energy which helps withdraw CO2 from the atmosphere.

Here's how one would procede:

1. Look for a dirty coal plant located in an optimal place: (1) close enough to a zone suitable for the construction of a solar thermal plant; (2) close enough to a region that provides sustainably sourced biomass; (3) close enough to potential geosequestration sites. The first of these is a prerequisite; the other two are flexible choices, because both biomass as well as captured CO2 can be transported over fairly long distances.

2. Begin with co-firing torrefied biomass pellets. Torrefied biomass - a new kid on the green block - gives the fuel a higher energy density and allows it to be transported over much longer distances than ordinary biomass; it can be stored like coal without the need for new infrastructures; it requires less energy to be crushed than ordinary biomass but also than coal, and can make use of the same grinding infrastructures as those used for coal; torrefied biomass can be readily co-fired at very large fractions. Co-firing torrefied biomass is the most straightforward and affordable way to cut emissions from existing coal plants.

3. When this operation is up and running, add solar thermal steam. The biomass and coal would provide the baseload for the intermittent solar thermal energy.

4. Gradually increase the biomass fraction to a ratio higher than 50% of all the carbon used as fuel in the power plant. So we can keep using coal, but simply much less of it. Keep adding biomass and solar steam until emissions from this power plant begin to near zero. Victory is in sight. We have a carbon-neutral baseload power plant.

5. But carbon-neutrality is not enough. More important actions are still ahead. By now carbon capture and sequestration (CCS) technologies should be commercially viable, and carbon prices on the market should allow the technology to be implemented without pushing up costs too much. So we add a CCS infrastructure to our hybrid power plant. This CCS infrastructure would capture and store CO2 from biomass, and make the power plant carbon-negative, instead of merely carbon-neutral.

Obviously, the strategy of taking over coal-fired power plants and turning them into climate-solution machines would come at an additional cost, but it would allow us to phase out coal, and actively trap and sequester CO2 from the atmosphere. This is a requirement if we ever want to go back to 350ppm, as leading climate scientists say we must.

The alternatives to capturing and storing atmospheric CO2 while generating electricity are all much more expensive (except, perhaps, for biochar produced in dedicated plants, with the char sequestered into soils). The advantages of the above strategy are that existing infrastructures can be used. This could be more feasible than building new ones or than betting our future on risky and exotic geo-engineering concepts.

biomass :: bioenergy :: solar thermal :: torrefaction :: co-firing :: carbon capture and storage :: carbon-negative :: negative emissions :: climate change :: coal ::

biomass :: bioenergy :: solar thermal :: torrefaction :: co-firing :: carbon capture and storage :: carbon-negative :: negative emissions :: climate change :: coal ::  --------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

4 Comments:

You say co-firing of over 50% torrefied biomass with coal could make a power plant carbon-negative. Think about that. If it's burning *any* fossil fuel, and not sequestering any of the resulting CO2, it is a net carbon emitter.

Combining solar thermal energy with existing thermal power is already a proven idea, by the way.

The 200MWe coal-fired power station at Liddell in the Hunter Valley in New South Wales, Australia has been using supplemental heat from a solar array for about two years now. This mid-scale demonstration project (currently contributing 38MWth on sunny days towards the power station’s capacity) has been an all-round success and is being expanded. Eventually the solar component of the power plant’s output may approach 25%.

http://www.abc.net.au/7.30/content/2007/s1837616.htm

http://www.abc.net.au/local/stories/2008/10/16/2393169.htm?site=upperhunter

This was the demonstration plant that proved the linear fresnel concentrating mirror technology now being commercialised in the USA by the firm Ausra. Ausra’s Canadian-born founder, David Mills, developed the technique whilst an academic at the University of Sydney.

Xoddam, the 50% refers to the C-content of the fuel. If more than 50% of the C-content of all the fuel burned in the power plant is biogenic in nature, and all the C is sequestered, then the plant would become carbon-negative.

Obviously, you'd need to take into account the energy needed to produce the biomass and the energy required to capture & transport CO2, but I didn't point to that, just to keep things simple.

Thanks a lot for the reference to the Australian example. Wasn't aware of this successful trial.

Cheers,

Jonas

Xoddam, you're right, I made a mistake in the post: in order to have a carbon-neutral plant, 100% of the C should be from biomass before applying CCS.

Thanks, yes -- obviously for carbon-neutrality any *fossil*-fuel-derived CO2 must be sequestered; the portion for which biomass is responsible need not be. Carbon returned to the soil as biochar from biomass feedstock that is partially used for energy may be considered "sequestered"; but torrefied "bio-coal" *is* the char and is entirely burned.

I made a typo above. The Liddell power station is 2000MWe, not 200. The solar thermal contribution is thus only about 2% of the plant's peak thermal energy consumption -- but growing. The solar array is the smaller regular field immediately to the west of the generator halls:

here's a map of the area

Note that the areas nearby presently devoted to open-cut coal mining are far larger than the small field used for collecting solar energy. About half the Hunter's coal production is burned locally and half is exported.

Post a Comment

Links to this post:

Create a Link

<< Home