Anaerobic digestion of livestock manure – an attractive option for renewable power

In the following guest contribution, Salman Zafar outlines the benefits of using livestock manure for the production of biogas. In many countries, livestock production generates large amounts of organic waste the treatment of which is either inefficient or non-existent. With high energy prices, using the resource as a feedstock for renewable methane production has become an interesting option.

In the following guest contribution, Salman Zafar outlines the benefits of using livestock manure for the production of biogas. In many countries, livestock production generates large amounts of organic waste the treatment of which is either inefficient or non-existent. With high energy prices, using the resource as a feedstock for renewable methane production has become an interesting option.Salman has been active in the field of renewable energy for the past few years. His areas of expertise include biomass utilization, waste-to-energy conversion and sustainable development. After obtaining his Masters degree in Chemical Engineering in 2004, he has been involved in industrial research on biomass-to-bioenergy conversion processes in different waste sectors. He has been instrumental in the implementation and successful operation of 1MW biogas plant based on animal manure in Punjab (India).

The generation and disposal of organic waste without adequate treatment result in significant environmental pollution. Besides health concerns for the people in the vicinity of disposal sites, degradation of waste leads to uncontrolled release of greenhouse gases (GHGs) into the atmosphere.

Conventional means, like aeration, is energy intensive, expensive and also generates a significant quantity of biological sludge. In this context, anaerobic digestion offers potential energy savings and is a more stable process for medium and high strength organic effluents. Waste-to-Energy (WTE) plants, based on anaerobic digestion of biomass, are highly efficient in harnessing the untapped renewable energy potential of organic waste by converting the biodegradable fraction of the waste into high calorific gases.

Apart from treating the wastewater, the methane produced from the biogas facilities can be recovered, with relative ease, for electricity generation and industrial/domestic heating.

Anaerobic digestion plants not only decrease GHGs emission but also reduce dependence on fossil fuels for energy requirements. The anaerobic process has several advantages over other methods of waste treatment. Most significantly, it is able to accommodate relatively high rates of organic loading. With increasing use of anaerobic technology for treating various process streams, it is expected that industries would become more economically competitive because of their more judicious use of natural resources. Therefore, anaerobic digestion technology is almost certainly assured of increased usage in the future.

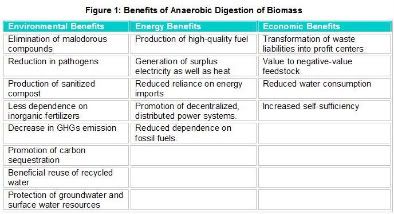

Anaerobic digestion provides a wide range of advantages over other conversion processes. These may be classified into three groups viz. environmental, economic and energy benefits (figure 1, click to enlarge).

Feedstocks

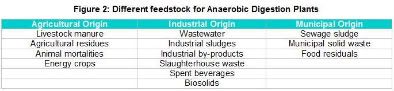

A wide range of feedstock is available for anaerobic digesters. In addition to MSW, large quantity of waste, in both solid and liquid forms, is generated by the industrial sector like breweries, sugar mills, distilleries, food-processing industries, tanneries, and paper and pulp industries. Out of the total pollution contributed by industrial sub-sectors, nearly 40% of the total organic pollution is contributed by the food products industry alone.

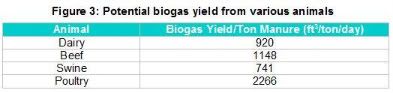

Food products and agro-based industries together contribute 65% to 70% of the total industrial wastewater in terms of organic load. Poultry waste has the highest per tonne energy potential of electricity per tonne but livestock have the greatest potential for energy generation in the agricultural sector.

Most small-scale units such as tanneries, textile bleaching and dying, dairy, slaughterhouses cannot afford effluent treatment plants of their own because of economies of scale in pollution abatement. Recycling/recovery/re-use of products from the wastes of such small-scale units by adopting suitable technology could be a viable proposition. Generation of energy using anaerobic digestion process has proved to be economically attractive in many such cases.

The urban municipal waste (both solid and liquid) – industrial waste coming from dairies, distilleries, pressmud, tanneries, pulp and paper, and food processing industries, etc., agro-waste and biomass in different forms – if treated properly, has a tremendous potential for energy generation. Fig 2 (click to enlarge) lists the possible feedstock for waste-to-energy plants based on anaerobic digestion of biomass.

Anaerobic digestion of livestock Manure – a case study

The livestock industry is an important contributor to the economy of any country. More than one billion tons of manure is produced annually by livestock in the United States. Animal manure is a valuable source of nutrients and renewable energy.

However, most of the manure is collected in lagoons or left to decompose in the open which pose a significant environmental hazard. The air pollutants emitted from manure include methane, nitrous oxide, ammonia, hydrogen sulfide, volatile organic compounds and particulate matter, which can cause serious environmental concerns and health problems:

energy :: sustainability :: biomass :: bioenergy :: manure :: livestock :: biogas :: anaerobic digestion :: methane :: waste-to-energy ::

energy :: sustainability :: biomass :: bioenergy :: manure :: livestock :: biogas :: anaerobic digestion :: methane :: waste-to-energy :: Anaerobic digestion is a unique treatment solution for animal agriculture as it can deliver positive benefits related to multiple issues, including renewable energy, water pollution, and air emissions. Anaerobic digestion of animal manure is gaining popularity as a means to protect the environment and to recycle materials efficiently into the farming systems. Waste-to-Energy (WTE) plants, based on anaerobic digestion of biomass, are highly efficient in harnessing the untapped renewable energy potential of organic waste by converting the biodegradable fraction of the waste into high calorific gases. The biomass of important domestic animals has been listed in Fig 3 (click to enlarge).

The establishment of anaerobic digestion systems for livestock manure stabilization and energy production has accelerated substantially in the past several years. There are more than 111 digesters operating at commercial livestock facilities in the United States which generated around 215 million kWh equivalent of useable energy. Besides generating electricity (170 million kWh), biogas is used as boiler and domestic fuel. Many of the projects that generate electricity also capture waste heat for various in-house requirements.

In the past, livestock waste was recovered and sold as a fertilizer or simply spread onto agricultural land. The introduction of tighter environmental controls on odour and water pollution means that some form of waste management is necessary, which provides further incentives for biomass-to-energy conversion.

Important factors to consider

The main factors that influence biogas production from livestock manure are pH and temperature of the feedstock. It is well established that a biogas plant works optimally at neutral pH level and mesophilic temperature of around 35o C. Carbon-nitrogen ratio of the feed material is also an important factor and should be in the range of 20:1 to 30:1.

Animal manure has a carbon - nitrogen ratio of 25:1 and is considered ideal for maximum gas production. Solid concentration in the feed material is also crucial to ensure sufficient gas production, as well as easy mixing and handling. Hydraulic retention time (HRT) is the most important factor in determining the volume of the digester which in turn determines the cost of the plant; the larger the retention period, higher the construction cost.

An emerging technological advance in anaerobic digestion that may lead to increased biogas yields is the use of ultrasound to increase volatile solids conversion. This process disintegrates solids in the influent, which increases surface area and, in turn, allows for efficient digestion of biodegradable waste.

Process description of WTE facility based on livestock manure

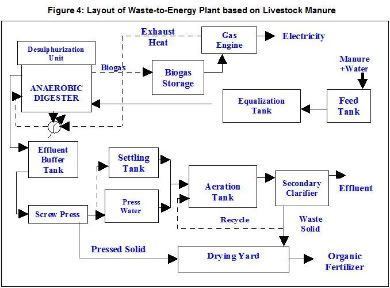

The layout of a typical biogas facility using livestock manure as raw material is shown in Fig 4 (click to enlarge). The fresh animal manure is stored in a collection tank before its processing to the homogenization tank which is equipped with a mixer to facilitate homogenization of the waste stream. The uniformly mixed waste is passed through a macerator to obtain uniform particle size of 5-10 mm and pumped into suitable-capacity anaerobic digesters where stabilization of organic waste takes place.

In anaerobic digestion, organic material is converted to biogas by a series of bacteria groups into methane and carbon dioxide. The majority of commercially operating digesters are plug flow and complete-mix reactors operating at mesophilic temperatures. The type of digester used varies with the consistency and solids content of the feedstock, with capital investment factors and with the primary purpose of digestion.

Biogas contains a significant amount of hydrogen sulfide (H2S) gas which needs to be stripped off due to its highly corrosive nature. The removal of H2S takes place in a biological desulphurization unit in which a limited quantity of air is added to biogas in the presence of specialized aerobic bacteria which oxidizes H2S into elemental sulfur.

Gas is dried and vented into a CHP unit to a generator to produce electricity and heat. The size of the CHP system depends on the amount of biogas produced daily. The digested substrate is passed through screw presses for dewatering and then subjected to solar drying and conditioning to give high-quality organic fertilizer. The press water is treated in an effluent treatment plant based on activated sludge process which consists of an aeration tank and a secondary clarifier. The treated wastewater is recycled to meet in-house plant requirements. A chemical laboratory is necessary to continuously monitor important environmental parameters such as BOD, COD, VFA, pH, ammonia, C:N ratio at different locations for efficient and proper functioning of the process.

The continuous monitoring of the biogas plant is achieved by using a remote control system such as Supervisory Control and Data Acquisition (SCADA) system. This remote system facilitates immediate feedback and adjustment, which can result in energy savings.

Utilization of biogas and digestate

An anaerobic digestion plant produces biogas as well as digestate which can be further utilized to produce secondary outputs. Biogas can be used for producing electricity and heat, as a natural gas substitute and also a transportation fuel. A combined heat and power plant system (CHP) not only generates power but also produces heat for in-house requirements to maintain desired temperature level in the digester during cold season.

CHP systems cover a range of technologies but indicative energy outputs per m3 of biogas are approximately 1.7 kWh electricity and 2.5kWh heat. The combined production of electricity and heat is highly desirable because it displaces non-renewable energy demand elsewhere and therefore reduces the amount of carbon dioxide released into the atmosphere.

In Sweden, the compressed biogas is used as a transportation fuel for cars and buses. Biogas can also be upgraded and used in gas supply networks. The use of biogas in solid oxide fuel cells is being researched.

The surplus heat energy generated may be utilized through a district heating network. Thus, there is potential scope for biogas facilities in the proximity of new housing and development areas, particularly if the waste management system could utilise kitchen and green waste from the housing as a supplement to other feed stock.

Digestate can be further processed to produce liquor and a fibrous material. The fiber, which can be processed into compost, is a bulky material with low levels of nutrients and can be used as a soil conditioner or a low level fertilizer. A high proportion of the nutrients remain in the liquor, which can be used as a liquid fertilizer.

Conclusions

Anaerobic digestion of biomass offer two important benefits of environmentally safe waste management and disposal, as well as the generation of clean electric power. The growing use of digestion technology as a method to dispose off livestock manure has greatly reduced its environmental and economic impacts.

Biomass-to-biogas transformation mitigates GHGs emission and harness the untapped potential of a variety of organic waste. Anaerobic digestion technology affords greater water quality benefits than standard slurry storage due to lower pollution potential. It also provides additional benefits in terms of meeting the targets under the Kyoto Protocol and other environmental legislations.

The livestock industry is a vitally important contributor to the economy of any country, regardless of the degree of industrialization. Animal manure is a valuable source of renewable energy; additionally, it has soil enhancement properties. Anaerobic digestion is a unique treatment solution for animal agriculture as it can deliver positive benefits related to multiple issues, including renewable energy, water pollution, and air emissions.

Anaerobic digestion of animal manure is gaining popularity as a means to protect the environment and to produce clean energy. There is an urgent need to integrate the digester with manure management systems for effective implementation of the anaerobic digestion technology to address associated environmental concerns and to harness renewable energy potential of livestock.

Salman Zafar is currently working as an independent renewable energy advisor. His articles and studies appear on a regular basis in reputed journals and magazines, both in India and abroad, and on leading web-portals. He can be reached at [email protected].

--------------

--------------

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

Mongabay, a leading resource for news and perspectives on environmental and conservation issues related to the tropics, has launched Tropical Conservation Science - a new, open access academic e-journal. It will cover a wide variety of scientific and social studies on tropical ecosystems, their biodiversity and the threats posed to them.

3 Comments:

Great article. In many areas of China, chicken manure is a critical component of the energy package. Villagers will build underground manure vats underneath their homes, which provides heat through the floor.

As well, a simple tube attached to such a manure digester provides a useful fuel for cooking.

So, is this restricted to subsistence villagers? Not at all!

http://www.eponline.com/articles/66221/

GE's Engines Power China's Chicken Manure-Biogas Plant

August 12, 2008

"GE Energy's ecomagination-certified Jenbacher gas engines will use biogas created from chicken manure to generate needed power and heat at a large chicken farm north of the China's capital city of Beijing. The plant is the first of its type in China, according to an Aug. 5 press release."

"The Beijing Deqingyuan Chicken Farm Waste Utilization plant comes as the country seeks innovative ways to meet its energy and environmental requirements."

"Providing 14,600 MWh of electricity per year, the project is designed to help reduce suburban electricity shortages."

Of course, that's not acceptable for the United States, since it would undercut the traditional natural gas market. That's also why biofuels are under constant attack in the U.S., and that's why we don't have electric cars, either.

Did you know that the first ethanol-electric hybrid vehicle was patented in 1903? Followed soon after by Prohibition, courtesy of Rockefeller of Standard Oil and his Christian Women's Temperance Movement.

In the U.S., it's all about protecting market share for the international fossil fuel corporations. Why, what would happen if the U.S. truly became energy-independent due to wind, solar and biofuels?

The global demand for fossil fuels would collapse, and everyone would turn to renewables overnight, is what would happen.

It could have happened 30 years ago, except that the fossil fuel industry and their billionaire shareholders seized control of the U.S. government and made sure that it didn't.

Thanks a lot for your comment, Ike. The lacklustre response of the US government in promoting renewable energy has been a major factor is our inability to harness the full potential of bioenergy. The Third World is doing better work to tap the energy potential of renewable resources.

Best wishes

Salman

I think there should be more anaerobic digesters in the agricultural community. They should also be more prevalent in the cities where everyone is producing a fuel source each and everyday.

Post a Comment

Links to this post:

Create a Link

<< Home