Canadian researchers study co-firing of peat and biomass with coal

Peat Resources Limited announces it will collaborate with the Ontario Centre for Excellence for Energy (OCE), Lakehead University and other partners on two research programs to examine peat fuel harvesting and processing systems. Funding for the program is managed by OCE under the auspices of the provincially-financed Atikokan Bioenergy Research Centre. OCE has allocated $720,000 over two years to a project aimed at sustainably harvesting the resource, while $880,000 has been granted for research on co-firing peat and biomass with coal, to lower the carbon emissions from power generation.

Peat Resources Limited announces it will collaborate with the Ontario Centre for Excellence for Energy (OCE), Lakehead University and other partners on two research programs to examine peat fuel harvesting and processing systems. Funding for the program is managed by OCE under the auspices of the provincially-financed Atikokan Bioenergy Research Centre. OCE has allocated $720,000 over two years to a project aimed at sustainably harvesting the resource, while $880,000 has been granted for research on co-firing peat and biomass with coal, to lower the carbon emissions from power generation.The first project, 'Environmental Effects of Wet Harvesting Peat as an Alternative Energy Source for the Atikokan Generating Station', will be led by scientists at Lakehead University (Thunder Bay) in conjunction with peatland experts from McMaster University (Hamilton). Peat Resources Limited is contributing to the project through provision of its unique knowledge and experience in peat fuel development and by providing access to peatlands in its licensed areas near Upsala (northwest Ontario) for demonstration and monitoring of restoration models. Results of related activities by the Company on its licensed peatland areas in western Newfoundland will also be contributed to the project.

In a second project partners will analyse the co-firing of peat and biomass with coal for power generation. This research is also being led by Lakehead University in partnership with CANMET Energy Technology Centre (Ottawa) and Ontario Power Generation. Peat Resources Limited will be supplying processed peat fuel pellets from its small-scale production facility in Stephenville (Newfoundland), firstly for pilot scale trials at CANMET and later, in 2008, for a large 500 tonne combustion trial by Ontario Power Generation at the Atikokan Generating Station.

Peat is found in deposits mainly in the earth’s north temperate latitudes. It is partially carbonized organic matter, originating from the decomposition of vegetation in bogs, marshes or heathland under waterlogged (anaerobic) conditions. Peat is an early stage of the development of coal and in the dried state is comprised of approximately 60% carbon:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: peat :: co-firing :: emissions :: Ontario :: Canada ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: peat :: co-firing :: emissions :: Ontario :: Canada :: Peat bogs develop over 10 to 12 thousand years, about 1 to 2 millimeters a year. A bog depends on rainfall to support its waterlogged condition. Generally the water table is very stable remaining within a few centimeters of the bog’s surface. The bogs contain both decomposed (fuel) and surficial (horticultural) peat, which is less humified and typically found in the top layers of the bog. Peat has two main applications: general soil improvement/growing medium (horticultural and agricultural) and increasingly as a fuel source for power generation.

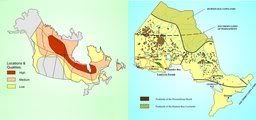

World’s Peat Deposits

Peat has been used as a fuel for thousands of years, particularly in Northern Europe. Peat resources throughout the world are enormous. In Finland, Sweden, Ireland and Russia peat is a significant source of electrical energy. Operations in these countries have mastered the harvest of peat bogs and the use of peat as a fuel for electrical power generation. In Canada and the United States, peat has been used most commonly as a soil conditioner in horticulture. Canada’s peat resources in Ontario have been mapped and tested. Their development for power generation is overdue given the need for clean power at a reduced environmental impact.

Ontario’s Peat Deposits

Canada has the world’s largest peat fuel resources estimated to be 41% of the world’s total of 43 billion tonnes, equivalent to 29 billion tonnes of coal.

A large proportion of these resources is found in Ontario (map, click to enlarge). Reserves are equivalent to 14 billion tonnes of coal, sufficient to satisfy its use for energy for centuries. Peat fuel development will reduce dependence upon out-of-province energy supplies, and will help Ontario achieve energy self-sufficiency.

There would be an opportunity, through local initiatives, for northern communities to play a dynamic long term role in Ontario’s peat fuel future. Peat utilization and associated development with participation by private industries could spur economic revival across Northern Ontario.

Peat Fuel Characteristics

Basic requirements for peat fuel are high calorific value, low ash content, low levels of sulphur and mercury, and high bulk density. Raw peat in Ontario which has undergone sufficient in-situ decomposition, meets these requirements.

To use raw peat as a fuel, dewatering is essential. In various parts of the world, bulk peat is burned at 50% moisture content, achieved by air drying raw peat, with or without mechanical dewatering. At this moisture content, its calorific value typically will range from 4,000 - 5,500 BTU/lb, similar to lignite.

Company sampling indicates the probable average will be approximately 9,600 BTU/lb in the dry state within the area of interest.

For peat fuel to compete with higher calorific fuels, it must be dewatered to about 10% moisture content. At that level, its calorific value will increase to between 7,200 - 10,000 BTU/lb, with the higher range levels from pre-selected bogs.

Both new research projects will provide important scientific and technical data supporting the application of peat fuel as an economic and environmentally attractive alternative to fossil fuels, such as coal, for power generation in Ontario and other North American jurisdictions.

Peat Resources Limited was formed to explore, develop and produce peat fuel for use in electricity generating stations and other facilities that require a long-term assured supply of economically competitive, environmentally favourable, and consistent quality fuel. With a strong resource base in Ontario and Newfoundland, an expert management team and unique knowledge of peat processing technology, the company is positioned to be the pre-eminent leader in this new North American energy industry.

References:

Peat Resources: Peat Resources Limited signs research collaboration agreement - December 12, 2007.

Ontario Center for Excellence for Energy.

Article continues

--------------

--------------

PetroChina Co Ltd, the country's largest oil and gas producer, plans to invest 800 million yuan to build an ethanol plant in Nanchong, in the southwestern province of Sichuan, its parent China National Petroleum Corp said. The ethanol plant has a designed annual capacity of 100,000 tons.

PetroChina Co Ltd, the country's largest oil and gas producer, plans to invest 800 million yuan to build an ethanol plant in Nanchong, in the southwestern province of Sichuan, its parent China National Petroleum Corp said. The ethanol plant has a designed annual capacity of 100,000 tons.

Forestry engineers from North Carolina State University (NCSU) are

Forestry engineers from North Carolina State University (NCSU) are

Thursday, December 20, 2007

Scientists find link between carbon dioxide and evolution of C4 grasses

C4 photosynthesis in grasses is one of the most successful ecological and evolutionary innovations in plant history, the scientists write. The C4 pathway is a fuel injection system for photosynthesis that increases the rate of leaf sugar production in hot climates. Most plants on Earth use the C3 photosynthetic pathway, which fixes carbon dioxide (CO2) from the atmosphere using the enzyme Rubisco. The C3 cycle uses this fixed CO2 and energy from sunlight to manufacture sugars. The process is inefficient because Rubisco is not saturated and not very specific, which means that it also fixes atmospheric oxygen. This inefficiency increases at high temperatures and low CO2 concentrations.

C4 plants overcome the inefficiency of C3 photosynthesis using a combination of anatomical and physiological tricks. First, the C3 cycle is isolated from the atmosphere within a leaf compartment. Secondly, the C4 cycle pumps CO2 into this compartment, filling it with CO2 and ensuring that Rubisco fixes nothing else. The 'pump' is powered by energy from sunlight, and works by using the enzyme PEPc to fix carbon in the form of bicarbonate (HCO3).

C4 plants are especially equipped to combat the energetically costly process known as photorespiration, that can occur under conditions of high temperature, drought, high salinity, and — with relevance to these latest findings — low carbon dioxide levels.

Although a combination of any of these factors might have provided the impetus behind the evolution of the various C4 lineages, it had been widely speculated that a drop in global carbon dioxide levels, occurring approximately 30 million years ago during the Oligocene period, may have been the major driving force. Establishing the link between the two, however, has proven difficult partly because there are no known fossils of C4 plants from this period.

Enter Pascal-Antoine Christin and colleagues from the University of Lausanne, Switzerland, who decided to take an alternative approach to date a large group of grasses. By using a 'molecular clock' technique, the authors were able to determine that the Chloridoideae subfamily of grasses emerged approximately 30 million years ago, right around the time global carbon dioxide levels were dropping. Furthermore, a model of the evolution of these grasses suggests that this correlation is not a trivial coincidence and instead reflects a causal relationship:

As the authors noted in their study, many of the C4 grasses evolved after the drop in global carbon dioxide levels 30 million years ago. How to explain this? The authors speculate that while an atmosphere low in carbon dioxide established the basic conditions necessary for C4 evolution, other ecological factors might be at work.

In light of this, the authors hope to apply the same approaches used in the paper described here to investigate the role of other variables, such as drought, salinity, and flooding, in the evolution of C4 plants.

In addition to improving our understanding of how climate changes influenced ecosystems in the past, such studies may allow predictions of how human activities could affect the planet in the future.

Indeed, with regard to global carbon dioxide levels, Christin and colleagues write, “besides its influence on climatic variables, increased CO2 concentration could trigger important ecological changes in major terrestrial ecosystems by affecting the distribution of C4-dominated biomes and the affiliated flora and fauna.”

This implies that a reversal of the conditions that favored C4 plants could potentially lead to their demise — a startling prospect if one considers the human race’s reliance on C4 crops like corn, sugarcane, sorghum, and millets.

The researchers include Pascal-Antoine Christin, Guillaume Besnard, Emanuela Samaritani, and Nicolas Salamin, all of the Department of Ecology and Evolution, Biophore, University of Lausanne, Switzerland; Melvin R. Duvall, Department of Biological Sciences, Northern Illinois University, DeKalb, Ill., USA; Trevor R. Hodkinson, Department of Botany, School of Natural Sciences, University of Dublin, Trinity College, Dublin, Ireland, and Vincent Savolainen, Imperial College, Berkshire, UK.

References:

Pascal-Antoine Christin, et al, "Oligocene CO2 Decline Promoted C4 Photosynthesis in Grasses", Current Biology, published online before print, December 20, 2007, DOI: 10.1016/j.cub.2007.11.058

Eurekalert: A link between greenhouse gases and the evolution of C4 grasses - December 20, 2007.

Article continues

posted by Biopact team at 9:34 PM 0 comments links to this post