RWE and AEP to test carbon capture and storage on hard coal-fired power plant in West Virginia

American Electric Power (AEP) and RWE plan to collaborate in the testing of carbon capture and storage (CCS) technology for modern coal-based power plants. To this end, the partners have now signed a Memorandum of Understanding. Alstom will also participate in this project, which will be implemented on the AEP hard coal-fired Mountaineer plant (1,300 MW) in New Haven, West Virginia.

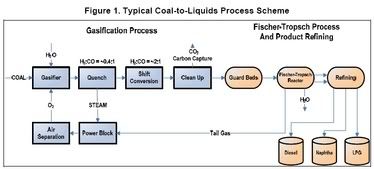

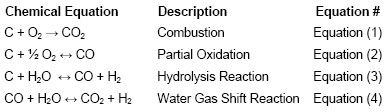

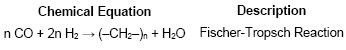

American Electric Power (AEP) and RWE plan to collaborate in the testing of carbon capture and storage (CCS) technology for modern coal-based power plants. To this end, the partners have now signed a Memorandum of Understanding. Alstom will also participate in this project, which will be implemented on the AEP hard coal-fired Mountaineer plant (1,300 MW) in New Haven, West Virginia.Alstom has developed a capture process based on ammonia that is to be used for the post-combustion capture of CO2 from flue gas. This process will be tested in a demonstration plant with an electrical capacity equivalent to 20 MW by capturing and scrubbing a corresponding slipstream from the flue gas. This way, up to 200,000 tons of CO2 are expected to be captured and stored on-site in deep saline formations – salt water-bearing strata – per year.

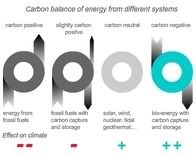

Biopact tracks developments in CCS, because the technology can be applied to biomass, resulting in carbon-negative energy and fuels. This kind of negative emissions energy, also known as 'bio-energy with carbon storage' (BECS) takes historic CO2 emissions out of the atmosphere. This sets it apart from both nuclear and renewables like wind, ordinary biofuels or solar, which are all 'carbon neutral' at best (schematic, click to enlarge, and see previous post, here and here).

Recently, RWE Power signed a collaboration agreement with BASF and Linde on the testing of new 'scrubbing agents' for capturing carbon in a pilot plant at RWE’s lignite-fired power plant site in Niederaussem (earlier post). Now it is joining American partners to validate the technology further.

Once the captured carbon is stored, the complete technology will have been tested. This area is managed by RWE's upstream subsidiary RWE Dea. The sub-project "storage", which will also be carried out by AEP, is subsidized by RWE Dea. Site-specific investigations of carbon storage capabilities, inter alia at the Mountaineer plant site, have been conducted in the US since 2002.

During the investigations, an approximately 2,740-meter exploratory well and seismic studies determined that the site was suitable for deep geological storage of CO2. Battelle Memorial Institute, a global science and technology enterprise and a leader in carbon storage research, is serving as the consultant on geological storage. RWE Dea will contribute its upstream and gas storage expertise.

The overall project – demonstration plant based on chilled ammonia and storage – is set to begin in 2009, provided that the application of this capture technology in a small-scale Wisconsin pilot plant operated by Alstom and the Electric Power Research Institute is successful. AEP and RWE are participating in this project as well:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture and storage :: bio-energy with carbon storage :: carbon-negative :: emissions :: climate change ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture and storage :: bio-energy with carbon storage :: carbon-negative :: emissions :: climate change :: Once commercial viability of the capture technology is validated at Mountaineer, AEP plans to use Alstom’s chilled ammonia process on one of the 450-MW coal-fired units at its Northeastern Station in Oologah, Oklahoma. This commercial-scale system is scheduled to be operational at the end of this decade. It is expected to capture about 1.5 million tons of CO2 a year. The CO2 captured at Northeastern Station will be used for enhanced oil recovery (EOR).

AEP and RWE are members of the e8, a non-profit international organization composed of the nine leading electricity companies from the G8 countries. The e8 promotes sustainable energy development through electricity sector projects in developing nations worldwide.

8 November 2007 - American Electric Power (AEP), RWE and Alstom will collaborate during a planned validation of commercial-scale application of carbon capture and storage technology on an existing AEP coal-fired power plant.

RWE will join a project AEP announced in March when it signed a deal with Alstom, for post-combustion carbon capture technology using Alstom's chilled ammonia process. RWE will also participate in an associated project for deep geological storage of captured CO2.

References:

RWE AG: RWE and AEP to test carbon capture and storage on existing Mountaineer hard coal-fired power plant in West Virginia - November 8, 2007.

Biopact: RWE Power, BASF and Linde to cooperate on CO2 capture technology - September 28, 2007

Biopact: A quick look at 'fourth generation' biofuels - October 08, 2007

Biopact: Carbon-negative bioenergy recognized as Norwegian CO2 actors join forces to develop carbon capture technologies - October 24, 2007

Biopact: Carbon-negative bioenergy is here: GreatPoint Energy to build biomass gasification pilot plant with carbon capture and storage - October 25, 2007

Article continues

--------------

--------------

Biopact's Laurens Rademakers is interviewed by Mongabay on the risks of large-scale bioenergy with carbon storage (BECS) proposals. Even though Biopact remains positive about BECS, because it offers one of the few safe systems to mitigate climate change in a drastic way, care must be take to avoid negative impacts on tropical forests.

Biopact's Laurens Rademakers is interviewed by Mongabay on the risks of large-scale bioenergy with carbon storage (BECS) proposals. Even though Biopact remains positive about BECS, because it offers one of the few safe systems to mitigate climate change in a drastic way, care must be take to avoid negative impacts on tropical forests.

A new international research initiative, linking the private and public sectors for the first time and

A new international research initiative, linking the private and public sectors for the first time and  Spanish renewable energy company

Spanish renewable energy company

Friday, November 09, 2007

International maritime body rejects risky ocean geoengineering

Geoengineering refers to intentional large-scale manipulation of land, ocean or atmosphere in an attempt to ‘fix’ climate change. The governments meeting at the London Convention were confronted with a rash of private ‘carbon trading’ schemes that claim to sequester greenhouse gases by dumping large quantities of iron, urea or other additives into the sea. These techniques, known collectively as 'ocean fertilisation', claim to draw climate change gases out of the atmosphere by prompting growth of plankton. The geoengineers seek to win ‘carbon credits’ as a financial reward for these activities – despite the fact that international scientific bodies have warned of potentially devastating ecological consequences for marine ecoystems (previous post).

Moreover, recently a 47 strong research team of leading oceanographers and biogeochemists from the international oceanographic mission KEOPS confirmed earlier doubts on the scientific merits of the technique, and warned for potentially negative effects. What is more, they even concluded that ocean fertilization as currently proposed won't work (here).

Other geoengineering proposals include emulating volcanoes' cooling effects by pumping sulphur into the atmosphere (debunked as dangerous - earlier post), creating a giant space mirror (which would be prohibitively costly), or generating highly reflective clouds (more here). Some of these proposals have been simulated and shown to be very risky (previous post).

In its Fourth Assessment Report, Working Group III of the International Panel on Climate Change (IPCC) discussed global warming mitigation strategies and said about geo-engineering:

The only technique seen as low risk, highly feasible and mentioned by the IPCC as one that could effectively help mitigate climate change, consists of the production of carbon-negative bioenergy (so-called 'bio-energy with carbon storage' or BECS systems). BECS is described as a geoengineering technique because it implies the creation of biomass plantations located at strategic places on the planet.

Ocean fertilization remains highly controversial, and the historic decision of the international body meeting in London this week came just as one company, Planktos, Inc., announced it had set sail from Florida, USA to dump iron in the ocean at an undisclosed location, possibly west of the Galapagos islands, known for their unique ecosystems.

A second private geoengineering outfit, Ocean Nourishment Corporation (ONC) of Australia, caused uproar this week in the Philippines with the discovery of a proposal to dump industrial urea in the ecologically sensitive Sulu Sea region. ONC is reportedly in discussions with the government of Morocco on another proposed dump:

Meanwhile, a third private geoengineering firm, Climos, Inc. of USA, attended the London Convention meeting where it proposed a voluntary “code of conduct” for ocean fertilisation – a proposal met with little enthusiasm.

The London Convention decisions were greeted with enthusiasm in the Philippines, where civil society organizations, small-scale fishers and environmentalists are protesting a proposal by Ocean Nourishment Corporation ”to dump urea in the Sulu Sea. The groups will hold a press conference on Monday 15 November in Manila to outline concerns and actions in the region.

According to Hope Shand of the ETC Group, a civil society organisation which screens the responsible use of new technologies, the London Convention has taken a first, important step to prevent geoengineering abuses. However, it maintains its call for a moratorium on large scale and commercial geoengineering projects until there is public debate, intergovernmental oversight and thorough assessment of social, economic and environmental impacts. Geoengineering techno-fixes are not an acceptable response to climate change, the ETC says.

References:

International Maritime Organization: London Convention.

ETC Group: London Convention Puts Brakes on Ocean Geoengineering - November 9, 2007.

Third World Network, SEARICE, Corporate Watch, ETC Group and Greenpeace South East Asia: Geoengineers prepare to pollute Philippine Seas as International Ocean Dumping Body Meets - November 5, 2007.

Rex Dalton, "Ocean tests raise doubts over use of algae as carbon sink", Nature 420, 722 (19 December 2002) | doi:10.1038/420722a

Biopact: The end of a utopian idea: iron-seeding the oceans to capture carbon won't work - April 26, 2007

Biopact: WWF condemns Planktos Inc. iron-seeding plan in the Galapagos - June 27, 2007

Biopact: Simulation shows geoengineering is very risky - June 05, 2007

Biopact: Climate change and geoengineering: emulating volcanic eruption too risky - August 15, 2007

Biopact: Capturing carbon with "synthetic trees" or with the real thing? - February 20, 2007

Biopact: IPCC Fourth Assessment Report: mitigation of climate change - May 04, 2007

Article continues

posted by Biopact team at 10:50 PM 0 comments links to this post