UK's largest biomass plant approved, biomass task force created

Scotland's Environment Minister Mike Russell has announced plans to boost wood supplies for renewable energy production at a plant in Lockerbie and throughout Scotland. He unveiled proposals to set up an industry-wide task force to tackle the issue when he visited the biomass station at Steven's Croft. Meanwhile, farmers in southern Scotland have become aware of the bright prospects for bioenergy and have begun turning over large slices of their land to growing willow, a short rotation coppice energy crop.

The new biomass project is the largest of its kind in the United Kingdom. The £90 (€133/US$178) million E.ON facility is expected to be fully operational by the end of the year. It will be capable of performing the following tasks:

- generating enough electricity to power 70,000 homes

- providing over 300 jobs in the forestry and energy farming sector

- displacing the emission of 140,000 tonnes of greenhouse gases each year

According to the recently published UK Biomass Strategy (earlier post), the total amount of wood available to England, Scotland and Wales for use as fuel is set to increase by 55% over the next decade, from 1.1million oven dry tonnes to 1.7million oven dry tonnes.

Task force

The new biomass plant is one of a number of green power projects across Scotland which are fuelled by wood. The increasing demand for timber supplies has prompted Mr Russell to examine how to meet the future needs of the sector. The Minister announced plans for the Forestry Commission Scotland to lead an industry task force to work to balance supply and demand in the long term.

The new task force will consider ways of bringing forward supplies from currently under-utilised sources such as forest residues, short rotation coppice and under-managed woodlands. It will also consider the impact of increased demand for wood fuel on the future balance between supply and demand within the wood processing sector:

bioenergy :: biofuels :: energy :: sustainability :: biomass :: wood :: short rotation coppice :: willow :: Scotland ::

bioenergy :: biofuels :: energy :: sustainability :: biomass :: wood :: short rotation coppice :: willow :: Scotland :: The task force will be led by Forestry Commission Scotland and will include representatives from the renewable energy, wood processing and land management sectors.

The announcement was made during a visit to E.ON's £90 million biomass plant in Lockerbie, the largest of its kind in the UK. Currently, E.ON expects to begin testing the plant after the summer and commission the station by the turn of the year. Overall,

The Forestry Commission Scotland has a number of woodfuel officers around the country who are working with a range of organisations to help develop and demonstrate the benefits of changing to wood fired systems. Already, the Commission has been helping both small and large scale woodfuel projects get under way and by next year is expected to be supplying well over 100,000 tonnes of material for woodfuel. Forestry Commission Scotland also has a contract to provide timber to the woodfuel supplier for the E.ON plant.

Head of Construction at E.ON Adrian Chatterton said “We were delighted to welcome the Minister to Steven’s Croft. When we commission the plant later this year it will be a flagship addition to our fleet.”

During Mr Russell's visit to the area he saw the whole woodfuel process in action from harvesting the timber through to the processing of it at James Jones before it is moved on to the E.ON plant. He also stopped in at the Barony College to discuss forestry training issues.

The Forestry Commission Scotland serves as the Scottish Government's forestry department. It manages 668,000 hectares of national forest land for multiple benefits, including nature conservation, public recreation, timber production, and rural and community development; supports other woodland owners with grants, felling licences, advice and regulation; promotes the benefits of forests and forestry; and advises Ministers on forestry policy.

E.ON is the UK's largest integrated power and gas company - generating, distributing and retailing electricity - and is part of the E.ON group, the world's largest investor-owned power and gas company. It employs around 16,000 people in the UK. E.ON is one of the leading green generators with 20 wind farms located from Cornwall to Northern Ireland. Two of their power stations burn biomass material with the new Steven’s Croft plant set to be the largest of its kind in the UK.

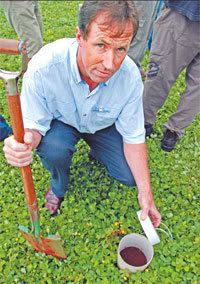

Becoming energy farmers

Given the growing interest for bioenergy, farmers across southern Scotland have already been turning over large slices of their land to growing willow. It is hoped much of it will eventually be used as fuel for the Steven's Croft biomass power station which is nearing completion outside Lockerbie.

The plant requires 220,000 tonnes of fuel a year and it is hoped local willow can provide about 45,000 tonnes.

The latest sowing of the willow crop has been at a six-and-a-half hectare field at Dalscone Farm in Dumfries and more is due to be planted shortly at Stranraer, Kilmarnock and Lockerbie.

Renewable Fuels, the company growing and supplying harvested willow for the station, is expanding its programme for developing energy crop production in Scotland. Contracts manager John Farrell said there was an increasing awareness of the revenue potential of the crop.

Increasingly popular

"Farmers in Dumfries and Galloway are becoming interested and we have already planted in four areas of the south west this spring and several more are in line," he said. A spokesman for the National Union of Farmers Scotland in Dumfries said he was aware that willow was becoming more popular.

"Farmers in Dumfries and Galloway are becoming interested and we have already planted in four areas of the south west this spring and several more are in line," he said. A spokesman for the National Union of Farmers Scotland in Dumfries said he was aware that willow was becoming more popular."There is potential there and there are certainly fields about the Lockerbie area where it is in," he said. "The siting of the plant in Lockerbie has encouraged some people to try and diversify into that area."

Image 1: simulation of the proposed E.ON plant in Lockerbie. Credit: E.ON.

Image 2: farmers in Scotland have taken up planting short rotation coppice like willow. Credit: BBC.

More information:

Forestry Commission: Minister announces wood fuel task force - June 15, 2007.

E.ON UK: Biomass page.

BBC: Farmers speculate on biomass boom - June 15, 2007.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Investments in the Philippines' biofuels industry are speeding up. The country has been identified by consultants as one of the countries in the South that both have the agro-ecological resources (land, climate, suitable crops) and the right the social, economic and policy frameworks as well as an excellent geographic location needed to become a highly successful biofuel production center that can supply East Asia (

Investments in the Philippines' biofuels industry are speeding up. The country has been identified by consultants as one of the countries in the South that both have the agro-ecological resources (land, climate, suitable crops) and the right the social, economic and policy frameworks as well as an excellent geographic location needed to become a highly successful biofuel production center that can supply East Asia ( Over the long to very long term, algae may offer an interesting potential for the production of biomass and biofuels. But much fundamental research is first needed to make algaeculture systems competitive and feasible, with some estimating that costs will have to come down 20 times before algae can compete with ordinary biofuels. Since algae research programs were discontinued in the early 1990s, no major biotech or engineering breakthroughs have been made in the sector, so we must assume that algal biomass yields remain the same as at that time, that is, between 30 and 50 tonnes per hectare - below the productivity of most tropical terrestrial crops (

Over the long to very long term, algae may offer an interesting potential for the production of biomass and biofuels. But much fundamental research is first needed to make algaeculture systems competitive and feasible, with some estimating that costs will have to come down 20 times before algae can compete with ordinary biofuels. Since algae research programs were discontinued in the early 1990s, no major biotech or engineering breakthroughs have been made in the sector, so we must assume that algal biomass yields remain the same as at that time, that is, between 30 and 50 tonnes per hectare - below the productivity of most tropical terrestrial crops ( An interesting technical

An interesting technical

The largest movement fighting for the distribution of unproductive rural property to landless peasant farmers in Brazil convenes for its fifth annual meeting in Brasília this week. The

The largest movement fighting for the distribution of unproductive rural property to landless peasant farmers in Brazil convenes for its fifth annual meeting in Brasília this week. The  Earlier we discussed how mobile phone use is skyrocketing in sub-Saharan Africa and other developing regions and how biofuels help make rural areas active participants of the era of fast and mobile communications. Mobile telephony drives social change and can transform agriculture, small businesses, micro-trade and grassroots politics for the better. Biofuels allow the technology to become available to the rural poor (

Earlier we discussed how mobile phone use is skyrocketing in sub-Saharan Africa and other developing regions and how biofuels help make rural areas active participants of the era of fast and mobile communications. Mobile telephony drives social change and can transform agriculture, small businesses, micro-trade and grassroots politics for the better. Biofuels allow the technology to become available to the rural poor ( In principle, biofuels can be produced with virtually no petroleum inputs. Farm equipment - irrigation machines, tractors, harvesting tools - can all be run on biofuels, and production plants can be fuelled by biomass (as is already being done in Brazil, where ethanol plants are powered by bagasse and even produce excess electricity they sell to the grid). The fact is especially important for agricultural regions in oil-importing developing countries that struggle with high oil prices. In an

In principle, biofuels can be produced with virtually no petroleum inputs. Farm equipment - irrigation machines, tractors, harvesting tools - can all be run on biofuels, and production plants can be fuelled by biomass (as is already being done in Brazil, where ethanol plants are powered by bagasse and even produce excess electricity they sell to the grid). The fact is especially important for agricultural regions in oil-importing developing countries that struggle with high oil prices. In an

In many developing countries the basic resources needed for the production of biofuels are present: abundant land, rain, sunshine, suitable energy crops and a huge need for stable fuel supplies and energy security. What they often lack though is agronomic and scientific knowledge and research capacities (

In many developing countries the basic resources needed for the production of biofuels are present: abundant land, rain, sunshine, suitable energy crops and a huge need for stable fuel supplies and energy security. What they often lack though is agronomic and scientific knowledge and research capacities (

Just when global consultancy Frost and Sullivan

Just when global consultancy Frost and Sullivan  “Biology generally likes sugar,” said Simmons, “since it offers an easy energy intermediate that can be converted into some usable output.” The Sandia team members, he said, are apparently among a handful of researchers looking at enzymes expressed by Sulfolobus and manipulating them in the laboratory with the objective of processing biomass into cellulosic ethanol.

“Biology generally likes sugar,” said Simmons, “since it offers an easy energy intermediate that can be converted into some usable output.” The Sandia team members, he said, are apparently among a handful of researchers looking at enzymes expressed by Sulfolobus and manipulating them in the laboratory with the objective of processing biomass into cellulosic ethanol. The Agência de Notícias Brasil-Arabe (ANBA)

The Agência de Notícias Brasil-Arabe (ANBA)  Brazil's state-owned oil company Petrobras and its associated company in Japan, Brazil-Japan Ethanol Co., Ltd. (BJE),

Brazil's state-owned oil company Petrobras and its associated company in Japan, Brazil-Japan Ethanol Co., Ltd. (BJE),  New York City's Mayor Michael Bloomberg

New York City's Mayor Michael Bloomberg  PetroSun, Inc., an algae-to-biofuels company

PetroSun, Inc., an algae-to-biofuels company  The U.S. Department of Energy's Joint Genome Institute (DOE JGI) has

The U.S. Department of Energy's Joint Genome Institute (DOE JGI) has  Biomass pyrolysis and carbon sequestration technology developed by Australian researchers along with

Biomass pyrolysis and carbon sequestration technology developed by Australian researchers along with  China may entirely switch to non-food energy crops such as

China may entirely switch to non-food energy crops such as  The search for innovative uses of biofuel byproducts continues. This is crucial to ensure biobased fuels become more commercially viable. Scientists from the U.S. Agricultural Research Service (ARS)

The search for innovative uses of biofuel byproducts continues. This is crucial to ensure biobased fuels become more commercially viable. Scientists from the U.S. Agricultural Research Service (ARS)  Earlier other researchers from the ARS

Earlier other researchers from the ARS  At their recent

At their recent  Genetically modified (GM) crops may contribute to increased productivity in sustainable agriculture, according to a major study published in the June 8 issue of the journal

Genetically modified (GM) crops may contribute to increased productivity in sustainable agriculture, according to a major study published in the June 8 issue of the journal  A recent

A recent

Saturday, June 16, 2007

California adopts 10 percent ethanol blend, major boost to biofuels

The California Air Resources Board adopted a resolution updating the predictive model for gasoline reformulation. All California refineries making gas sold in the state will have to blend 10 percent ethanol into their gas to meet new fuel standards set by Gov. Arnold Schwarzenegger starting Dec. 31, 2009.

Industry groups said the ruling will almost double demand for the biofuel in California, which last year used about 1 billion gallons (3.8 billion liters) of ethanol, or nearly one-fifth of the total consumed across the United States.

Blending more ethanol into gasoline will improve air quality in California and reduce dependency on foreign oil. The decision blends in with Governor's Schwarzenegger's Low Carbon Fuel Standard (LCFS) executive order. The goal of the LCFS is to ensure that the mix of fuel sold in California market deliver, on average, lower greenhouse gas (GHG) emissions. By 2020, the LCFS is expected to produce at least a 10 percent reduction in the carbon content, replace 20 percent of all on-road fuels with lower carbon alternatives, and more than triple the size of the state's renewable fuels market.

Boost to biofuels market

"Once the market starts to fall in line like this, it shows the demand is there and is growing," said Bruce Scherr, CEO of Informa Economics Inc., a Memphis-based consulting firm specializing in renewable fuels. A handful of other states - including Connecticut, Minnesota and Hawaii - have mandates for the use of 10 percent ethanol, or E-10, according to the Renewable Fuels Association.

A surge in demand will be created as large states like California, Texas and New York roll out legislation forcing gas stations to sell a more environmentally friendly mix, analysts said. That growth is aided by the Energy Policy Act of 2005, which gives small refiners a federal tax credit for using the biofuel:

"While many alternative fuels exist in the market, ethanol is one that can be blended into today's gasoline with no change to our current cars," Schwarzenegger commented. "It is critical that government continue reducing barriers so that alternative fuels can increasingly penetrate our transportation fuels markets.

If refineries still cannot meet clean air standards with 10 percent ethanol in their fuel mix, they can reduce emissions from other sources by donating money to programs that take polluting vehicles off the road, among other alternatives, said board spokesman Dimitri Stanich.

California's decision may have an impact on global ethanol producers like Brazil and other countries in Latin America, who export to the United States. The biofuels they produce are more efficient and less costly than corn based ethanol, the main biofuel used today in the U.S. In March, the United States and Brazil signed a biofuels cooperation agreement, but President Lula did not succeed in making the US abandon its US$0.54/gallon tariff on imported ethanol (earlier post).

In March, the United States imported 629,000 barrels of ethanol mainly from Latin America (previous post).

More information:

California Environmental Protection Agency, Air Resources Board: Groundwork Begun for Greater Use of Ethanol in California's Gasoline - June 15, 2007.

USNewswire: Gov. Schwarzenegger Issues Statement on Air Resources Board's Adoption of Measure in Support of Ethanol, Renewable Transportation Fuel - June 15, 2007.

California Renewable Fuels Partnership.

Article continues

posted by Biopact team at 2:35 PM 0 comments links to this post