Bleak future for coal, unless CCS becomes feasible - MIT report

The coal industry has been receiving several blows over the past few months, with the UN saying coal can only continue to fuel the future if carbon capture and storage (CCS) techniques (illustration, click to enlarge) are implemented massively (earlier post). Likewise, a top NASA scientist said he wanted no more of the climate destructive fuel at all (earlier post). And now a new study by the Massachusetts Institute of Technology reiterates that the fossil fuel faces a bleak future unless CCS is developed on a commercial scale and fast.

The coal industry has been receiving several blows over the past few months, with the UN saying coal can only continue to fuel the future if carbon capture and storage (CCS) techniques (illustration, click to enlarge) are implemented massively (earlier post). Likewise, a top NASA scientist said he wanted no more of the climate destructive fuel at all (earlier post). And now a new study by the Massachusetts Institute of Technology reiterates that the fossil fuel faces a bleak future unless CCS is developed on a commercial scale and fast.Leading academics from an interdisciplinary MIT panel issued the report that examines how the world can continue to use coal, an abundant and inexpensive fuel, in a way that mitigates, instead of worsens, the global warming crisis. The study, "The Future of Coal--Options for a Carbon Constrained World" advocates that the U.S. - the world's second largest coal consumer - assume global leadership on this issue through adoption of significant policy actions.

Led by co-chairs John Deutch, Institute Professor, Department of Chemistry, and Ernest J. Moniz, Cecil and Ida Green Professor of Physics and Engineering Systems, the report states that carbon capture and sequestration (CCS) is the critical enabling technology to help reduce carbon dioxide emissions significantly while also allowing coal to meet the world's pressing energy needs.

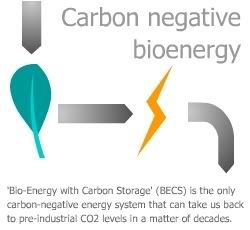

At the Biopact, we track developments in the technology and the political debate around CCS, because ultimately, the technique offers an avenue towards the creation of the greenest of all possible energy systems, namely 'Bio-Energy with Carbon Storage' (BECS). Using CCS to store carbon dioxide from fossil fuels, comes down to a climate-neutral operation. BECS however is the only concept that provides energy while being radically carbon negative. Using such a system would allow societies to continue to consume energy, while at the same time taking more and more CO2 out of the atmosphere. By using climate-neutral biomass instead of coal, and by storing the emissions of the burned biomass underground using CCS, plants become machines that capture carbon from the past. Scientists think BECS can take us back to pre-industrial CO2 levels in a matter of decades.

At the Biopact, we track developments in the technology and the political debate around CCS, because ultimately, the technique offers an avenue towards the creation of the greenest of all possible energy systems, namely 'Bio-Energy with Carbon Storage' (BECS). Using CCS to store carbon dioxide from fossil fuels, comes down to a climate-neutral operation. BECS however is the only concept that provides energy while being radically carbon negative. Using such a system would allow societies to continue to consume energy, while at the same time taking more and more CO2 out of the atmosphere. By using climate-neutral biomass instead of coal, and by storing the emissions of the burned biomass underground using CCS, plants become machines that capture carbon from the past. Scientists think BECS can take us back to pre-industrial CO2 levels in a matter of decades.In order to make BECS work, biomass must become an affordable, abundant and easily tradeable energy source. Luckily, all these requirements can be met. According to some projections, biomass is already the cheapest of all fuels (both fossil and renewable) (earlier post). Add the vast and untapped potential of sustainable energy plantations in the (sub)tropics (which the EU recently studied), and the emergence of efficient international biomass trading (earlier post), then it is clear BECS might become feasible.

But CCS must first become viable as a sequestration technique. According to Deutch, "As the world's leading energy user and greenhouse gas emitter, the U.S. must take the lead in showing the world CCS can work. Demonstration of technical, economic and institutional features of CCS at commercial scale coal combustion and conversion plants will give policymakers and the public confidence that a practical carbon mitigation control option exists, will reduce cost of CCS should carbon emission controls be adopted and will maintain the low-cost coal option in an environmentally acceptable manner."

Moniz added, "There are many opportunities for enhancing the performance of coal plants in a carbon-constrained world--higher efficiency generation, perhaps through new materials; novel approaches to gasification, CO2 capture and oxygen separation; and advanced system concepts, perhaps guided by a new generation of simulation tools. An aggressive R&D effort in the near term will yield significant dividends down the road and should be undertaken immediately to help meet this urgent scientific challenge."

Key findings in the MIT study include:

biofuels :: energy :: sustainability :: coal :: carbon dioxide :: carbon capture and storage :: bio-energy with carbon storage :: biomass :: climate change :: carbon negative ::

biofuels :: energy :: sustainability :: coal :: carbon dioxide :: carbon capture and storage :: bio-energy with carbon storage :: biomass :: climate change :: carbon negative :: - Coal is a low-cost, per BTU, mainstay of both the developed and developing world, and its use is projected to increase. Because of coal's high carbon content, increasing use will exacerbate the problem of climate change unless coal plants are deployed with very high efficiency and large-scale CCS is implemented.

- CCS is the critical enabling technology because it allows significant reduction in carbon dioxide emissions while allowing coal to meet future energy needs.

- A significant charge on carbon emissions is needed in the relatively near term to increase the economic attractiveness of new technologies that avoid carbon emissions and specifically lead to large-scale CCS in the coming decades. We need large-scale demonstration projects of the technical, economic and environmental performance of an integrated CCS system. We should proceed with carbon sequestration projects as soon as possible. Several integrated large-scale demonstrations with appropriate measurement, monitoring and verification are needed in the United States over the next decade with government support. This is important for establishing public confidence for the very large-scale sequestration program anticipated in the future. The regulatory regime for large-scale commercial sequestration should be developed with a greater sense of urgency, with the Executive Office of the President leading an interagency process.

- The U.S. government should provide assistance only to coal projects with carbon dioxide capture in order to demonstrate technical, economic and environmental performance.

- Today, Integrated Gasification Combined Cycle appears to be the economic choice for new coal plants with CCS. However, this could change with further research development and demonstration, so it is not appropriate to pick a single technology winner at this time, especially in light of the variability in coal type, access to sequestration sites and other factors. The government should provide assistance to several "first of their kind" coal utilization demonstration plants, but only with carbon capture.

- Congress should remove any expectation that construction of new coal plants without carbon dioxide capture will be "grandfathered" and granted emission allowances in the event of future regulation. This is a perverse incentive to build coal plants without carbon dioxide capture today.

- Emissions will be stabilized only through global adherence to carbon dioxide emission constraints. China and India are unlikely to adopt carbon constraints unless the United States does so and leads the way in the development of CCS technology.

- Key changes must be made to the current Department of Energy research development and demonstration program to successfully promote CCS technologies. The program must provide for demonstration of CCS at scale; a wider range of technologies should be explored; and modeling and simulation of the comparative performance of integrated technology systems should be greatly enhanced.

The report is available online at web.mit.edu/coal.

About the MIT study: A group of MIT faculty has undertaken a series of interdisciplinary studies about how the United States and the world would meet future energy demand without increasing emissions of greenhouse gases. The first study, "The Future of Nuclear Power," appeared in 2003.

Generous financial support from the Alfred P. Sloan Foundation, the Pew Charitable Trusts, the Energy Foundation, the Better World Fund, the Norwegian Research Council and the MIT Office of the Provost is gratefully acknowledged. Shell provided additional support for part of MIT's studies in China.

More information:

MIT's dedicated website on the interdisciplinary study 'The Future of Coal'.

Article continues

--------------

--------------

The city of Rome has announced plans to run its public bus fleet on a fuel mix of 20 per cent biodiesel. The city council has signed an accord that would see its 2800 buses switch to the blended fuel in order to cut greenhouse gas emissions and local air pollution. A trial of 200 buses, if successful, would see the entire fleet running on the biofuel mix by the end of 2008. Estimates put the annual emission savings at 40,000 tonnes of carbon dioxide.

The city of Rome has announced plans to run its public bus fleet on a fuel mix of 20 per cent biodiesel. The city council has signed an accord that would see its 2800 buses switch to the blended fuel in order to cut greenhouse gas emissions and local air pollution. A trial of 200 buses, if successful, would see the entire fleet running on the biofuel mix by the end of 2008. Estimates put the annual emission savings at 40,000 tonnes of carbon dioxide.

The Dow Chemical Company

The Dow Chemical Company  The Rajasthan-based

The Rajasthan-based  A group of research institutions from Hawaii has

A group of research institutions from Hawaii has

Monday, March 19, 2007

EU Commission launches major program to 'open up' Central African Republic

European Commissioner for Development and Humanitarian Aid Louis Michel recently visited the CAR to take stock of the security situation, promote political stabilisation in the country and obtain commitments from the government in the matter of governance.

While there, he signed two financing agreements: one concerns €55 million for a comprehensive programme of institutional support and measures to open up the country, including the construction of a section of the Bouar-Garoua Boulai road, and the other €13.6 million for a programme to reduce multilateral and domestic arrears. These two operations make the Commission the CAR’s biggest donor.

The CAR is a large landlocked country (see map, click to enlarge) with a great untapped agricultural potential. It has one of the lowest population densities in the world (6.5 inhabitants/square kilometer). The CAR's 4 million inhabitants' average arable land availability is around 19 hectares per person, the highest ratio after Gabon and the DRCongo (see the FAO's Terrastat database).

Agriculture forms the backbone of the CAR's economy providing 55% of its GDP, and the sector employs around 70% of the country's population, which mainly lives in the countryside. Urbanisation in the CAR progresses very slowly, in contrast with other African countries. But despite the country's agricultural potential, its people belong to the poorest of the world, with an estimated yearly income of only US$300 per person. Large-scale bioenergy production offers a possible way out.

One of the main obstacles to the Central African Republic's development is its landlocked status, its lack of transport infrastructures and the high fuel import bills that drain its treasury. These factors strengthen each other and result in a negative synergy that keeps the CAR closed off from the outside world and its people in poverty. Transport fuels are extremely expensive in the country, because they have to be shipped in over the Congo and Ubangi rivers, and shortages are very frequent.

Given these factors, the CAR is one of those countries where the creation of a decentralised biofuels industry makes absolute sense. Locally produced transport fuels would reduce energy import bills and make it possible to gradually start exporting agricultural products, not in the least biofuels and biomass. The sustainable biomass production potential of the CAR is high, as a recent study by the EU's UCLOS project showed. The former french colony is one of those countries that make sub-Saharan Africa's long-term bioenergy potential so large (earlier post).

The CAR currently depends on international aid to survive economically and on NGOs for services the state is not capable of offering for lack of funds. Large-scale bioenergy production for exports could help end this dreadful situation.

In order to make this possible, basic investments in agriculture but especially in transport infrastructures are urgently needed. The country's main arteries, the Ubangi and Sangha rivers, are navigeable for most of the year, but it is the Congo river, in the DRCongo, which is the main bottleneck and requires most investment. Luckily, both the EU - with an extremely useful €5 billion infrastructure fund for Africa - and the World Bank are contributing to opening up these rivers, which are the backbone of Central African economies. Both institutions are very active in stabilising the region and reviving it, after it came out of a decade long civil war. Infrastructure, energy and agriculture are the key words in this large investment strategy. If these resources are put to good use, conditions are favorable to get a biofuels industry off the ground.

The following is a rough overview of indicators of the CAR's agricultural potential - the country currently uses less than 5% of its arable land - which we think can be illustrated with the help of some very basic maps:

A main advantage of the CAR is the fact that its population density is extremely low, and its population is relatively evenly spread out over the country's territory, meaning it has an abundant land resource and a fairly low risk profile when it comes to potential social conflicts over land:

The CAR has a varied subtropical climate with the South being permanently humid, the largest, central part having a rainy and a dry season, with the upper North-east of the country being hot, dry and plagued by desertification. The country's main rivers are looked at as a great resource for irrigation. In the 1960s, they were the object of an (overly ambitious) plan to divert their water into Lake Chad. The copious amount of water from the Ubangi would revitalize that dying lake and provide livelihoods in fishing and enhanced agriculture to tens of millions of food insecure Central African and Sahelian people. Recently, the idea has regained attention because the cost and the technical hurdles faced by the proposal are supposedly quite manageable, compared to what it can achieve in uplifting the fate of those poorest of the African poor.

When it comes to the basic land suitability for different crops in the CAR, we refer to the following maps (all made by the Biopact, drawing on the FAO's database of Land Suitability Maps for Rainfed Cropping). Even though it remains to be seen which type of crops would make the best mix for the CAR's biofuel future, the maps, based on the agro-ecological zoning methodology, show the basic potential for different widely grown sugar and starch rich crops that can be seen as feedstocks for liquid biofuels. All maps show the suitability for rainfed cropping, with high inputs. The potential for crops under irrigation is not taken into account.

The exact hectarages and the potential yields for the crops can be found at the International Institute for Applied Systems Analysis's (IIASA) database of Global Agro-Ecological Zones (produced in collaboration with the FAO).

According to these datasets, the CAR has a total land area of 45.3 million hectares suitable for agriculture, out of a total territory of 61.8 million hectares. Of this land base, 29.8 million hectares are very suitable and suitable, 11 million ha are moderately suitable and 4.5 million are marginally suitable for rainfed agriculture under high inputs. The suitable area does not change much as inputs decrease (meaning low-input agriculture is feasible on a large scale). (Note: all datasets from the IIASA are formatted as *.xls files).

Sweet potato

Cassava

Sorghum

Soybeans

Sugarcane

Tree crops

Vast parts of the Central African Republic are also suitable for plantation trees such as eucalyptus and acacia - for which no AEZ maps and exact numbers are available. But there are some good data on this from a recent study carried out by European research organisations who looked at the sustainable production potential for woody biomass that could fuel energy intensive industrial sectors such as steel making, identified the country as one of the most interesting in sub-Saharan Africa.

In short, this brief overview of some of the indicators of the CAR's agricultural situation clearly indicates that the country can in theory become a strong bioenergy producer. If the growing food, fiber, fodder and fuel needs of the CAR's steadily growing (but still very small population) are met, the country still has a large resource base left for green energy production, which it can export.

But there is of course a wide gap between purely theoretical projections and assessments relying on natural factors (land, climate, etc...) and the economic, concrete potential, which is determined by man-made factors: from the political stability and investment climate in a country over its infrastructures to the way its leaders manage their country.

It is on this front that Louis Michel's initiative must be situated. The European Commissioner known for making Central Africa the prime focus of his policies said during his trip: “I am delighted to be making this visit, which is the first by a European Commissioner to the Central African Republic in over 30 years. The European Commission is proud to be assisting political change in the country. It is time to build on the achievements. I am delighted to see the inclusive dialogue that has been initiated between the government, opposition parties and civil society. We are aware of the difficult regional situation, which is exacerbated by the Darfur crisis, and want to give a tangible demonstration of our solidarity with the Central African Republic.”

Under the 9th European Development Fund (EDF, 2002-2007), the European Commission has focused on infrastructure, macroeconomic support and strengthening sound management of public finances. A further €15.5 million has been committed from the Peace Facility for Africa to help finance the multinational force (FOMUC) mandated by the Central African Economic and Monetary Community (CEMAC) until 30 June 2007. In particular, 2007 will see the commitment of €8 million for a support project for the health sector.

The country's initial allocation of €109 million under the 10th EDF (2008-2013) will be used to develop secondary towns and the surrounding areas by restoring the government’s authority and decentralised services (education, health, water, sanitation, tracks, infrastructure, communications networks, justice, policing and energy).

Cooperation with the CAR had been partially suspended in the wake of March 2003’s coup d’état. Close consultations ensued between the European Union and the CAR under Article 96 of the Cotonou Agreement. The Commission provided €3 million to help finance the organisation of elections in 2005. Full cooperation was restored in July 2005.

Article continues

posted by Biopact team at 6:12 PM 0 comments links to this post