Algae company AlgoDyne invests in miscanthus

AlgoDyne Ethanol Energy Inc., the biofuel company that earlier said it found a technology to harvest algae blooms from the open ocean (previous post), has meanwhile acquired approximately 800 acres (324ha) of agricultural land in Saskatchewan to grow terrestrial biomass. The company now announces it has decided to increase the total amount of land to up to 3000 acres (1215ha) to grow bioenergy crops such as miscanthus.

AlgoDyne Ethanol Energy Inc., the biofuel company that earlier said it found a technology to harvest algae blooms from the open ocean (previous post), has meanwhile acquired approximately 800 acres (324ha) of agricultural land in Saskatchewan to grow terrestrial biomass. The company now announces it has decided to increase the total amount of land to up to 3000 acres (1215ha) to grow bioenergy crops such as miscanthus.At the Biopact we give algae companies the benefit of the doubt, even though we remain skeptical about the feasibility and efficiency of large-scale biofuel production from micro-organisms (earlier post). AlgoDyne is not the first company to silently invest in ordinary energy crops as it discreetly phases out the algae venture.

Again, the company says it made a 'discovery', this time that by applying certain aspects of its proprietary enzyme technology gained from its micro-algae research to grain crops and especially to miscanthus, the EROI (Energy Return on Investment) of ethanol from land grown biomass can be increased significantly to a sustainable economic level. There is no patent or any published information backing up this 'discovery' of enzymatic cellulose conversion.

AlgoDyne will establish its own biomass distribution network to supply the ever increasing demand for biomass for ethanol production:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: miscanthus :: cellulose :: ethanol :: algae ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: miscanthus :: cellulose :: ethanol :: algae :: AlgoDyne says its main focus still lies on the development of micro-algae as the primary source of biomass for ethanol production. The Company has gained strong evidence (never published or demonstrated) for the "vast superiority of micro-algae regarding the YPE (yield per effort) / EROI compared to land grown biomass". The company is determined to exploit the boom in grain crops "to expand research on its disruptive technology to produce ethanol from micro-algae."

Miscanthus is a genus of about 15 species of perennial grasses. Miscanthus giganteus has been trialed as a biofuel in Europe since the early 1980s. It can grow to heights of more than 3.5m in one growth season. Its dry weight annual yield can reach 25t/ha (10t/acre). The rapid growth, low mineral content and high biomass yield of Miscanthus make it a favorite choice as a biofuel. After harvest, it can be burned to produce heat and power turbines. The resulting CO2 emissions are equal to the amount of CO2 that the plant used up from the atmosphere during its growing phase, and thus the process is greenhouse gas-neutral.

Article continues

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

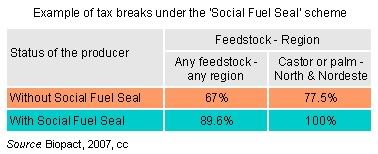

Even though the Brazilian biofuels revolution has been a scientific, agronomic and technological success, it has not been a very equitable one. Professor

Even though the Brazilian biofuels revolution has been a scientific, agronomic and technological success, it has not been a very equitable one. Professor

The Spring issue of

The Spring issue of  Top venture capitalist Vinod Khosla, the founder of SUN Microsystems and a major investor in both Brazilian biofuels (

Top venture capitalist Vinod Khosla, the founder of SUN Microsystems and a major investor in both Brazilian biofuels ( The debate over bioenergy must be seen as part of the broader discussion on climate change and energy security. The most primitive of fuels - biomass - has become interesting because of its relative low costs compared to fossil fuels and renewables like wind or solar (

The debate over bioenergy must be seen as part of the broader discussion on climate change and energy security. The most primitive of fuels - biomass - has become interesting because of its relative low costs compared to fossil fuels and renewables like wind or solar ( Scientists from NOAA’s

Scientists from NOAA’s  A new joint-venture, Van Der Horst Biodiesel, is

A new joint-venture, Van Der Horst Biodiesel, is

When the Founding Fathers of modern Europe signed the Treaties of Rome in 1957, they created the 'European Atomic Energy Community' and the 'European Economic Community' which aimed to strengthen peace through economic cooperation, amongst countries that had just come out of a World War that had destroyed their societies and left their economies in ruin. A few years before, in 1951, six European countries - Belgium, France, Germany, Italy, Luxemburg and the Netherlands - had created the European Coal and Steel Community to manage their heavy industries collectively. From the very beginning, energy and economic cooperation were the building blocks of what would later become the EU.

When the Founding Fathers of modern Europe signed the Treaties of Rome in 1957, they created the 'European Atomic Energy Community' and the 'European Economic Community' which aimed to strengthen peace through economic cooperation, amongst countries that had just come out of a World War that had destroyed their societies and left their economies in ruin. A few years before, in 1951, six European countries - Belgium, France, Germany, Italy, Luxemburg and the Netherlands - had created the European Coal and Steel Community to manage their heavy industries collectively. From the very beginning, energy and economic cooperation were the building blocks of what would later become the EU. Former President Jacques Delors understands this sense of crisis and calls for the EU to be more ambitious in its attempts to unite citizens behind a new vision. On the question what urgent measures should be undertaken in order achieve this, Delors recommends the creation of a genuine European Energy Community, modelled on the concept of the early European Coal and Steel Community.

Former President Jacques Delors understands this sense of crisis and calls for the EU to be more ambitious in its attempts to unite citizens behind a new vision. On the question what urgent measures should be undertaken in order achieve this, Delors recommends the creation of a genuine European Energy Community, modelled on the concept of the early European Coal and Steel Community. A new FAO

A new FAO  Since dedicated CA implements - such as knife-rollers and direct seeders - are not widely available, the project will take Kenyans and Tanzanians to Brazil to study CA technologies and will design strategies for developing a sustainable equipment supply chain in the subregion. Lessons learned will be "up-scaled" and disseminated throughout Africa.

Since dedicated CA implements - such as knife-rollers and direct seeders - are not widely available, the project will take Kenyans and Tanzanians to Brazil to study CA technologies and will design strategies for developing a sustainable equipment supply chain in the subregion. Lessons learned will be "up-scaled" and disseminated throughout Africa. For the first time a large, truly multidisciplinary team of scientists has studied the complex tradeoffs between incomes for poor farmers in the tropics, biodiversity loss and the way ecosystems cope with deforestation. The results are interesting in the context of biofuel production in the tropics. They show that while conversion of tropical forest for agriculture results in significant declines in biodiversity and carbon storage, farming cash crops such as cacao under the partial shade of high canopy trees can provide a way to balance economic gain with environmental considerations.

For the first time a large, truly multidisciplinary team of scientists has studied the complex tradeoffs between incomes for poor farmers in the tropics, biodiversity loss and the way ecosystems cope with deforestation. The results are interesting in the context of biofuel production in the tropics. They show that while conversion of tropical forest for agriculture results in significant declines in biodiversity and carbon storage, farming cash crops such as cacao under the partial shade of high canopy trees can provide a way to balance economic gain with environmental considerations. Governments both in the EU and the US view switchgrass and other herbaceous energy crops as plentiful and low-cost alternatives to corn or sugarbeets for making the next generation of biofuels.

Governments both in the EU and the US view switchgrass and other herbaceous energy crops as plentiful and low-cost alternatives to corn or sugarbeets for making the next generation of biofuels. During the

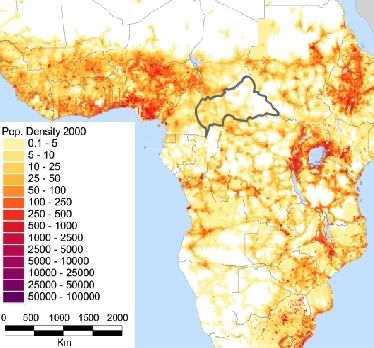

During the  Another typical 'South-North-South' cooperation agreement is in the making between Brazil and Italy, whose state-owned energy companies want to join forces to tap Africa's huge sustainable bioenergy production potential (

Another typical 'South-North-South' cooperation agreement is in the making between Brazil and Italy, whose state-owned energy companies want to join forces to tap Africa's huge sustainable bioenergy production potential (

In recent years there has been significant and high-profile interest in the use of biofuels as possible alternatives to fossil fuels, as part of a move to reduce carbon dioxide emissions. Although combustion accounts for most biofuel use, there has also been significant research into biofuel gasification, a transformation step needed to make synthetic biofuels (

In recent years there has been significant and high-profile interest in the use of biofuels as possible alternatives to fossil fuels, as part of a move to reduce carbon dioxide emissions. Although combustion accounts for most biofuel use, there has also been significant research into biofuel gasification, a transformation step needed to make synthetic biofuels (

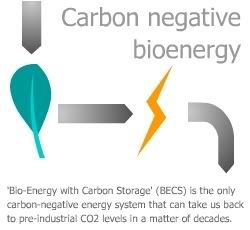

At the Biopact, we track developments in the technology and the political debate around CCS, because ultimately, the technique offers an avenue towards the creation of the greenest of all possible energy systems, namely

At the Biopact, we track developments in the technology and the political debate around CCS, because ultimately, the technique offers an avenue towards the creation of the greenest of all possible energy systems, namely  The Dow Chemical Company

The Dow Chemical Company  A group of research institutions from Hawaii has

A group of research institutions from Hawaii has  We start with a development that is most remarkable, because it is set to transform the ethanol industry by allowing a move towards highly efficient, small-scale and decentralised production, away from large industrial production systems that are only open to big investors.

We start with a development that is most remarkable, because it is set to transform the ethanol industry by allowing a move towards highly efficient, small-scale and decentralised production, away from large industrial production systems that are only open to big investors.

Saturday, March 24, 2007

Researchers develop bioplastic that breaks down into biodiesel after use

The new plastic is made from plant oils and has remarkable properties, such as being tougher and more durable than petroleum-based polyethylenes. Additionally, the bioplastic can be placed in a simple container where it is safely broken down to liquid fuel, ready for use in cars. The concept thus shortcuts a costly waste-management process and simplifies fuel logistics. The innovation clearly illustrates the cyclical nature of the bioeconomy: the 'waste'-stream of one bioproduct becomes the feedstock for another bioproduct. In such a circular, cradle-to-cradle concept, there is no real 'waste'.

The Defense Advanced Research Projects Agency (DARPA) has awarded the researchers US$2.34 million to advance this innovative technology. The military is very interested because, when on campaign, army units produce vast waste-streams that are not treated and pollute the environment, whereas fuel logistics are often problematic. With the new plastic, both problems are solved at once.

The commercialization of the technology will also lead to a new source of green energy for households worldwide.

Professor Richard Gross, director of Polytechnic University's National Science Foundation (NSF) Center for Biocatalysis and Bioprocessing of Macromolecules (CBBM) developed the new bioplastic using vegetable oils. He also partnered with DNA 2.0, a biotechnology company specializing in gene synthesis, to develop enzymes that can both synthesize and break the fuel-latent plastic down into biodiesel after its use:

"Polytechnic University has a long history of innovation, and we are confident Professor Gross' research will revolutionize how we produce and consume biofuels," noted Jerry M. Hultin, president of Polytechnic University. "Gassing up at the pump could be part of the past thanks to the possibility of this research."

The process of converting biogengineered fuel-latent plastics into biodiesel is of interest to DARPA since the U.S. military can use this technology on the frontline.

"Military units generate substantial quantities of packaging waste when engaging in stationary field operations. If we can turn this waste into fuel, we will see a double benefit - we will reduce the amount of waste that we have to remove, and we will reduce the amount of new fuel that we must deliver to the units," explained Khine Latt, program manager for DARPA's Mobile Integrated Sustainable Energy Recovery program.

The next phase of the research will entail developing a more efficient low-cost process for both manufacturing the bioplastic and converting it into biodiesel. The personal generation of biodiesel is an important step in developing green technologies and reducing waste.

Bioplastics are most often associated with sugar and starchy feedtocks, from which polylactic acid is obtained, the building block for a particular kind of biodegradable plastic (earlier post). But more and more, plant oils are being used as well (an example).

Article continues

posted by Biopact team at 1:50 PM 1 comments links to this post