World's cleanest energy one step closer: EESTech acquires CCS technology that can be applied to biomass

In an interesting development, EESTech, Inc. today announced the acquisition of a leading carbon capture and storage technology from Canadian company, HTC Purenergy. The technology can be applied to EESTech's biomass capable Hybrid Coal Gas Turbine (HCGT) technology, which means carbon-negative bioenergy - the most radical climate friendly form of energy - has come one step closer. The acquisition is structured around a share swap, with EESTech acquiring 100% of the shares in CO2 Technologies Pty Ltd, a wholly owned subsidiary of HTC Purenergy, giving EESTech the exclusive rights to commercialise the CCS technology in China, India, Japan, Australia, New Zealand, Malaysia, Indonesia, Brunei, Thailand, the Philippines and Singapore.

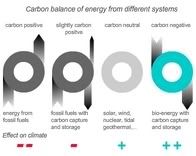

In an interesting development, EESTech, Inc. today announced the acquisition of a leading carbon capture and storage technology from Canadian company, HTC Purenergy. The technology can be applied to EESTech's biomass capable Hybrid Coal Gas Turbine (HCGT) technology, which means carbon-negative bioenergy - the most radical climate friendly form of energy - has come one step closer. The acquisition is structured around a share swap, with EESTech acquiring 100% of the shares in CO2 Technologies Pty Ltd, a wholly owned subsidiary of HTC Purenergy, giving EESTech the exclusive rights to commercialise the CCS technology in China, India, Japan, Australia, New Zealand, Malaysia, Indonesia, Brunei, Thailand, the Philippines and Singapore.Renewable energy technologies like wind or solar power, as well as nuclear, deliver 'carbon neutral' electricity, that is, energy that doesn't add new greenhouse gases to the atmosphere. Power generated from fossil fuels on the contrary is strongly 'carbon positive' as it emits copious amounts of climate destructive CO2. To make fossil energy cleaner, researchers are looking into capturing the CO2 from power plants before it enters the atmosphere, and then to store the gas in depleted oil & gas fields, or in other geological formations such as saline aquifers.

But carbon capture and storage (CCS) has its critics. They fear the gas might leak, even though geologists are confident that there are enough suitable sites that can lock up the gas for centuries. Another point of criticism is that the investments in CCS are taking away money from the renewables industry.

Both these arguments can be side-stepped by the most radical of clean energy technologies, namely the production of renewable carbon-negative bioenergy. This form of energy, also called 'bio-energy with carbon storage' (BECS) effectively results in negative emissions. This means that each time you utilize electricity from BECS, you actually take historic emissions out of the atmosphere. Solar and wind merely prevent new emissions from occuring, but carbon negative bioenergy goes much further, by effectively taking previous emissions out of the carbon cycle (schematic, click to enlarge).

This makes BECS very radical, and the cleanest of all energy technologies. No other energy technology can deliver negative emissions. A coal plant without CCS generates around 800 grams of CO2 per kWh of electricity produced; CO2 emissions from a coal plant with CCS can be reduced to significantly to under 100 g/kWh; solar and wind offer low carbon emissions over their lifecycle, ranging from 30 to 100 g CO2eq/kWh; but electricity from a negative emissions bioenergy system generates -1000 g CO2/kWh, that is minus a thousand grammes.

So the argument that CCS investments divert money away from renewables is incorrect, because biomass is a renewable resource. In fact, the sooner CCS technologies become less costly and the faster research can be focused on developing dedicated capture technologies for biogenic gases, the sooner we can tackle climate change with BECS. Scientists have found that if applied on a planetary scale, BECS systems can take us back to pre-industrial atmospheric CO2 levels by mid-century and thus solve the climate crisis in a safe and relatively short time.

The CCS technology acquired today by EESTech goes a far way in developing this futuristic vision of a world powered by negative emissions. It was developed in conjunction with the leading University Of Regina's Greenhouse Gas Technology Centre and the International Test Centre for Carbon Capture, in Saskatchewan, Canada, a major research consortium for CCS technologies.

The process works in three steps: capturing the CO2 from flue gases via designer solvents (which can be designed to work on flue gases from the combustion of biomass), compressing the gas, and transporting it to the geosequestration site (see animation).

Capturing CO2

The exhaust gas from the power plant is the source of CO2.The exhaust gas is cooled before it reaches the capture process itself in order to optimise the process. The flue-gas cooler is the largest consumer of cooling water in the process, typically using 50% of the cooling water.

The exhaust gas from the power plant is the source of CO2.The exhaust gas is cooled before it reaches the capture process itself in order to optimise the process. The flue-gas cooler is the largest consumer of cooling water in the process, typically using 50% of the cooling water.- The flue-gas will meet some physical resistance within the capture plant on its way to the atmosphere, and this will result in a certain pressure drop in the exhaust gas. In order to ensure that the power plant’s gas turbine does not suffer a loss of power because of the capture facility, a blower is located in the flue-gas duct, either before the cooling unit or between it and the actual capture plant.

- From the blower, the gases are brought to the bottom of an absorption tower, which is filled with a packing material that offers a large surface that the absorption solvent follows on its way down through the tower. The solvent is an amine or a mixture of amines dissolved in water, which absorb the CO2 in the flue-gas as it flows upwards through the tower. The CO2 removal efficiency for flue-gases from gas-turbine exhaust will typically be 85%.

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon-negative :: bio-energy with carbon storage :: negative emissions :: carbon capture and storage :: geosequestration :: climate change ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon-negative :: bio-energy with carbon storage :: negative emissions :: carbon capture and storage :: geosequestration :: climate change :: - After the CO2 has been captured by the amine, it has to be released by heating the solvent. The desorption of CO2 takes place in the desorption tower, also known as a stripper. This is done by allowing the amine containing the CO2 to flow down the packing material that fills the tower, while steam and CO2 flow upwards. The steam has two functions:a) it transfers the necessary heat to the amine, and b) it draws the released CO2 out of the tower. The mixture of steam and CO2 that exits the top of the stripper is cooled down, and most of the steam is condensed while the CO2 remains in a gaseous phase.

- The water is pumped back to the stripper while the CO2 is directed to the dehydration and compression stages and on to transportation.

- The amine flows from the bottom of the stripper to the reboiler, where the steam used in the desorption process is generated. The heat for the reboiler is steam generated by heat from an external source. This reboiler is the largest consumer of heat in the CO2 separation process.

- A flow of virtually CO2-free amine solution leaves the boiler and is led back to the absorber, where it once again absorbs CO2.

- In the absorption tower, the reaction between CO2 and amine produces heat, with the result that a certain amount of amine and water will evaporate during the absorption process and be carried upwards through the tower along with the flue-gases. The gas is saturated with steam and amines . As well as losing a portion of the amines, the water losses will also be large. In order to minimise water losses and emissions of amines, a water-wash process is integrated at the top of the absorption tower.

- Cold water with a low concentration of amines washes the flue-gases, dissolving the amines while the water balance is maintained by the steam being condensed by the cold water.

- When the solvent comes into contact with the flue-gases, the amines will also react with other components in the flue-gas, such as O2 and NOx. How much of these are absorbed will vary from one amine to another, and will also depend on the design of the absorption tower. These reactions form heat-stable salts that will not be released from the amine solution by the stripping process. Since the amine mixture is circulated between the absorber and the desorber, the amount of heat-stable salts in the solvent will gradually rise. After a certain period of time, the concentration of these salts will be so high that the CO absorption rate will be reduced. This is handled by the use of a reclaiming unit.

- A side stream of the circulated solvent is heated so that the water and amines evaporate and are led back to the process. When the water and amines have been boiled off, what remains at the bottom of the reclaimer is a viscous liquid that must be disposed of. The waste will contain some amines and water, but will consist mostly of heat-stable salts.

After the CO2 has been separated from the flue-gas in the capture plant, it must be dried and compressed. This is done in a multistage process of compression, cooling and water separation.

After the CO2 has been separated from the flue-gas in the capture plant, it must be dried and compressed. This is done in a multistage process of compression, cooling and water separation.- Pressure, temperature and water content all need to be adapted to the method of transportation (pipeline or vessel) and pressure requirement at the storage site. A typical compression and dehydration process for pipeline transportation is illustrated schematically (click to enlarge).

- CO2 from the capture plant arrives at the dehydration and compression stage at about room temperature and at a little above atmospheric pressure. Apart from the CO2, the gas contains some steam and small fractions of impurities (nitrogen, oxygen, and traces of amines and other substances).

- When CO2 is being transported by pipeline, compression requirements are determined by the supply pressure at the delivery site and the pressure drop through the transportation pipeline. The pressure in the pipeline should always be high enough to ensure that the CO2 is in a supercritical state, i.e. above 50 – 70 bars, depending on the temperature. Where a simple storage solution is involved, the offshore supply pressure is 70 – 100 bars while the pressure requirement for EOR may be higher. In order to meet pressure requirements of this order, the pressure of the CO2 may be anything from 150 bars to 300 bars or higher as it leaves the capture plant, depending on the type of transportation and the storage pressure involved.

- The combination of water and CO2 in a pipeline creates corrosive conditions, requiring the water content to be kept low and monitored continuously in order to avoid corrosion and hydrate formation.

The integration of both technologies has been independently validated as cost-effective climate change technologies. When the HCGT and CCS systems are combined they become the world's first stand-alone Hybrid CCS System that is non-disruptive to industry. The combined efficiencies of the HCGT and CCS Systems will set a new industry benchmark by reducing the cost of carbon capture and sequestration by up to 40%:

The combined technologies are globally relevant technologies in the world of today. They can be fitted as a stand-alone carbon capture service to a vast proportion of existing and planned [...] power stations. This acquisition will position EESTech, Inc. as a leader in this fast-growing marketplace and as a provider of clean coal and carbon capture technologies that are economically and environmentally sustainable. - Murray Bailey, EESTech CEOEESTech's integrated hybrid system will cut emissions of both carbon dioxide and fugitive methane, which is 21 times more harmful as a greenhouse gas than CO2.

Using captured CO2 for Enhanced Oil Recovery (EOR) is another option that will benefit oil field operators by extending the life of depleted oil reserves, and by yielding an increase of up to 6.5 barrels of oil for every new ton of CO2 injected into suitable oil formations.

EESTech, Inc. is well positioned to capitalize on both the energy-intensive resource boom, and the unfolding industries that will need to meet energy demands in a carbon-constrained global economy.

The announcement follows EESTech, Inc.'s September news that it had signed model power purchase and fuel supply terms with Beijing XingliYuan Science & Technology Company to provide Hybrid Coal Gas Turbines applicable to coal mine companies in China.

The ability of the HCGT to use waste as a fuel to generate both the energy and steam required for carbon capture and sequestration offer tremendous cost savings. We look forward to working with EESTech, Inc. and the opportunity to supply cost-effective CO2 capture for the emerging EOR / Sequestration markets in the Asia Pacific region. - Lionel Kambeitz, CEO of HTC PurenergyEESTech, Inc. was incorporated in the US and is a US Corporation permitted to trade stock on the US Bulletin Board.

Images: all CCS schematics courtesy of HTC Pure Energy; comparison of carbon emissions of different forms of energy, Biopact.

References:

HTC Pure Energy: publications on its CCS technologies.

--------------

--------------

Lithuania's first dedicated biofuel terminal has started operating in Klaipeda port. At the end of November 2007, the stevedoring company Vakaru krova (VK) started activities to manage transshipments. The infrastructure of the biodiesel complex allows for storage of up to 4000 cubic meters of products. During the first year, the terminal plans to transship about 70.000 tonnes of methyl ether, after that the capacities of the terminal would be increased. Investments to the project totaled €2.3 million.

Lithuania's first dedicated biofuel terminal has started operating in Klaipeda port. At the end of November 2007, the stevedoring company Vakaru krova (VK) started activities to manage transshipments. The infrastructure of the biodiesel complex allows for storage of up to 4000 cubic meters of products. During the first year, the terminal plans to transship about 70.000 tonnes of methyl ether, after that the capacities of the terminal would be increased. Investments to the project totaled €2.3 million.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home