Choren announces site for world's first large-scale biomass-to-liquids plant

German biofuels company Choren announces [*German] it is to build the world's first large-scale biomass-to-liquids (BtL) plant in Schwedt, a city in Brandenburg, near the Polish border. The facility will be built in the vicinity of the PCK Refinery, where it will convert 200,000 tons of biomass into ultra-clean synthetic biofuels. Choren's site selection offers an insight into the complex logistical, technical, and scientific infrastructures that drive the production of next-generation biofuels.

German biofuels company Choren announces [*German] it is to build the world's first large-scale biomass-to-liquids (BtL) plant in Schwedt, a city in Brandenburg, near the Polish border. The facility will be built in the vicinity of the PCK Refinery, where it will convert 200,000 tons of biomass into ultra-clean synthetic biofuels. Choren's site selection offers an insight into the complex logistical, technical, and scientific infrastructures that drive the production of next-generation biofuels.Choren managing director Tom Blades presented 2010 as the year in which construction would begin with fall 2009 being the period in which the €800 million investment should be finalized. The announcement was hailed by both federal, state and local politicians.

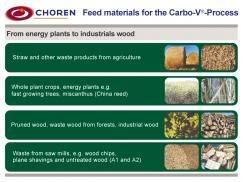

Schwedt came out as the best of 60 possible locations in Germany. Five further locations were drawn onto a map where future plants could be built. Which factors did Choren look at when selecting this site? The proximity to the oil refinery made Schwedt a site where synergies can be created concering the supply of heat and energy. In addition the Uckermark region has sufficient land potential for raw material production and an abundance of existing biomass residues that can be converted into synfuel (table, click to enlarge).

Moreover the presence of the Fachhochschule Eberswalde (University of Applied Sciences) in the area makes it possible to draw on advanced scientific research into bioenergy (on fast-rotation energy trees). The university already operates experimental fields in the proximity of Schwedt, on which it trials fast-growing woody energy crops for cellulosic biofuels.

Synthetic biofuels such as Choren's 'SunDiesel' are considered to be renewable fuels of the of the second generation. The ultra-clean fuels have an exceptionally low emissions profile. They are obtained from the gasification of a wide range of biomass feedstocks with the syngas liquefied via the Fischer-Tropsch process. Choren's technology, the 'Carbo-V Process' is a three-stage gasification process involving the following sub-processes: (1) low temperature gasification, (2) high temperature gasification and (3) endothermic entrained bed gasification.

During the first stage of the process, the biomass (with a water content of 15 – 20 %) is continually carbonized through partial oxidation (low temperature pyrolysis) with air or oxygen at temperatures between 400 and 500 °C, i.e. it is broken down into a gas containing tar (volatile parts) and solid carbon (char).

During the second stage of the process, the gas containing tar is post-oxidized hypostoichiometrically using air and/or oxygen in a combustion chamber operating above the melting point of the fuel’s ash to turn it into a hot gasification medium.

During the third stage of the process, the char is ground down into pulverized fuel and is blown into the hot gasification medium. The pulverized fuel and the gasification medium react endothermically in the gasification reactor and are converted into a raw synthesis gas. Once this has been treated in the appropriate manner, it can be used as a combustible gas for generating electricity, steam and heat or as a synthesis gas for producing SunDiesel.

The Carbo-V process has the following advantages over conventional biomass gasification:

- A wide range of feed materials can be used

- A high-quality gas with a tar content below minimum detection limits and a very low concentration of methane (<>

- Complete exploitation of the feed material used * Numerous fields of application (electricity, heat, cold, methanol, synthetic automotive fuels, waxes etc.) * Conversion efficiency for gasification (cold gas efficiency) > 80 %

- Electrical energy efficiency levels of up to 35 %

- Low emission levels

- The ash is converted into a solid bonded slag granulate suitable for building purposes

The synthetic biodiesel is an ultra-clean fuel which:

- has a high cetane number and therefore much better ignition performance than conventional diesel fuel,

- has no aromatics or sulfur and significantly reduces pollutants from exhaust emissions,

- can be used without any adjustment to existing infrastructure or engine systems,

- is largely CO2-neutral

energy :: sustainability :: biomass :: bioenergy :: biofuels :: energy crops :: gasification :: Fischer-Tropsch :: biomass-to-liquids :: synthetic biofuels :: Germany ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: energy crops :: gasification :: Fischer-Tropsch :: biomass-to-liquids :: synthetic biofuels :: Germany :: Schwedt wants to become a leading bioenergy hub. In the vicinity of the oil refinery a set of new biofuel factories have already been established, in which biodiesel, bio-ethanol and wood pellets for heating purposes are produced.

On the one hand we are pleased with each new job which revitalizes our city. On the other hand we are even more excited to be the host to the development of an entirely new industrial sector with enormous growth potential. - Juergen Polzehl, mayor of SchwedtThe city of Choren's choice is located in one of former East Germany's most economically problematic regions. The Federal Government's Special Envoy for the New States ('Beauftragte der Bundesregierung für die neuen Länder', who is still tasked with integrating Eastern German 'Länder' into the more prosperous West), also the Federal Minister of Transport, Wolfgang Tiefensee, said the investment is 'a trailblazing project for the development of second generation biofuel production' and it proves that investment assistance for companies that want to establish themselves in East Germany remains a central component of the policy for the reconstruction of the regions economic structure.

The company is currently building the world’s industrial scale BTL plant (Beta plant) at its Freiberg site. From 2008, the plant is expected to produce approximately 15,000 metric tons of fuel a year. This would be sufficient to meet the annual requirements of some 15,000 cars.

But Choren's large plans for biomass-to-liquids and the first 200,000 ton plant to be located in Schwedt received a boost recently when both Volkswagen and Daimler - two of Germany's largest automakers - became minority shareolders in the company. These companies offer the key to ensure that a framework is created for the sustainable market introduction of the BtL fuels.

Last month the German Government also announced an ambitious new Biofuels Roadmap in which it massively increases the country's biofuels target, doubling it from 5% by 2010 to 10% by that year, and to 20% by 2020. This way it doubles the EU's biofuel targets (which require 10% of all fuels to be biofuels by 2020). The new plan is aimed at encouraging the development of next-generation biofuels such as synthetic biodiesel.

References:

Choren: Weltweit erste Großanlage für Biomasse-Kraftstoff soll in Schwedt entstehen - December 18, 2007.

Biopact: Volkswagen and Daimler become shareholders of BTL company CHOREN, aim to mass introduce ultra-clean synthetic biofuels - October 11, 2007

Biopact: Germany massively increases biofuels targets to kickstart next generation fuels: 10% in 2010, 20% in 2020 - November 22, 2007

--------------

--------------

PetroChina Co Ltd, the country's largest oil and gas producer, plans to invest 800 million yuan to build an ethanol plant in Nanchong, in the southwestern province of Sichuan, its parent China National Petroleum Corp said. The ethanol plant has a designed annual capacity of 100,000 tons.

PetroChina Co Ltd, the country's largest oil and gas producer, plans to invest 800 million yuan to build an ethanol plant in Nanchong, in the southwestern province of Sichuan, its parent China National Petroleum Corp said. The ethanol plant has a designed annual capacity of 100,000 tons.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home