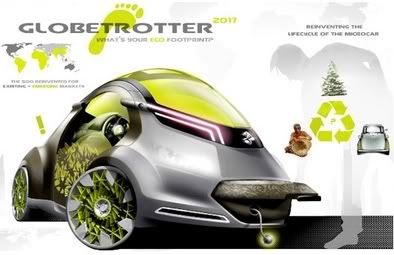

The bioeconomy at work: Globetrotter 'bio-car' wins Young Designer of the Year Award

Ever imagined driving in an ultra lightweight, bioplastic car running efficiently on green electricity and taking carbon dioxide out of the atmosphere by doing so? If designer Harsha Ravi has his way, this will be the future of sustainable automobiles. Winning the conveted Young Designer of the Year award, Harsha Ravi has envisioned a release from dependence on fossil fuels with an emphasis on eco-friendly vehicle technologies and cutting back the weight and bulk of today’s gas-guzzlers. Ravi’s concept uses a carbon-neutral, strong bioplastic body with 12 percent petroleum-based/88 percent corn-based plastic that reduces manufacturing energy 30 percent.

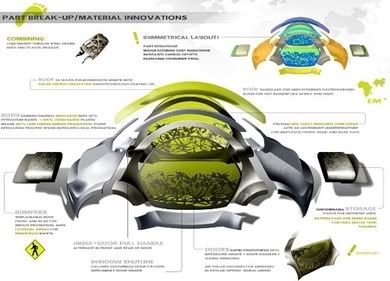

And there’s much more - a zinc-air fuel cell, nano-paper battery, airless tires, nanopaints to absorb solar energy while parked to charge its batteries, and natural fiber woven seat material. This car is lightweight, functional, frugal - the ultimate 'tread lightly' automotive feast for the environment-savvy consumer. If its batteries are charged with bio-electricity - the most efficient and cost-effective form of renewable energy - Ravi's concept becomes a fully carbon-neutral 'bio-car'. What's more, if it were to be powered by carbon negative electricity from biomass, the carbon dioxide of which is captured and sequestered, it could even take emissions out of the atmosphere!

Interestingly, the entire vehicle is 'designed-for-disassembly', a design philosophy based on the increasingly important 'cradle to cradle' concept, which makes designers think of how their products can be broken down and its individual parts reused in similar or totally different products. The bioplastic components conform to the idea as well, because when they are biodegraded in soils, they become nutrients for plants from which new bioplastics can be made - a perfectly closed loop that differs significantly from mere 'recycling'.

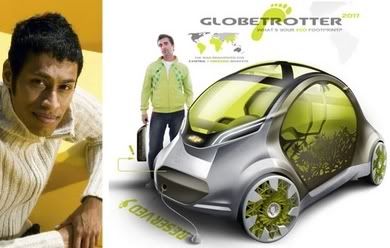

Harsha Ravi designed his first car at the age of 13. His childhood penchant for sketching people and landscapes finally earned him accolades when he was awarded the title of the Australian Young Designer of the Year, 2007, in October, for designing a futuristic car for 2017. The award has been instituted by the magazine Wheels in conjunction with the Australian Design Awards. It recognizes and rewards Australia’s outstanding young automotive designers:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioplastic :: biopolymer :: biocomposites :: negative emissions :: design-for-disassembly :: cradle-to-cradle ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioplastic :: biopolymer :: biocomposites :: negative emissions :: design-for-disassembly :: cradle-to-cradle ::

Ravi, a Chennai-born NRI studying in Australia, is a part-time student at Monash University, Melbourne, Australia. He is pursuing a bachelor’s degree in Industrial/Product design at the university. His environment-friendly car, Globetrotter, was selected out of 17 entries at this year’s competition. The eight-judge panel included experts like GM Holden design director Antony Stolfo, Australian International Design Awards executive director Brandon Glen, Nielsen Design Associates managing director Sandy McNeil and Newcastle University industrial design head Graham Paver.

This year’s competition marked the 50th anniversary of the Fiat 500 and the designs were required to be 2+1, 500cc and 500 kg. The judging criteria included innovation, intelligence of design, visual impact and form, functionality, visual impact and form, functionality, originality, quality and design for manufacture and maintenance, ergonomics and semantics, safety and environmental considerations:

The award entitles him to a three-month internship of $50,000 at GMs North American design studio in 2008, where he would work with a team of international students on an advanced design project. He would also get a $15,000 trip to a major international motor show in 2008, funded by aXcess of Australia. The other designs that were highly commended at the competition were H500 by Tanveerul Islam and Roll up by Edwin Yi Yuan.

Biocomposites and bioenergy are becoming increasingly attractive to future mobility concepts. Earlier this year researchers at the University of Warwick presented their first environmentally-friendly racing car with tyres made from potatoes and brake pads from cashew nut shells - it runs on biofuels (previous post). Likewise, Canadian universities have teamed up to develop a car that is over 90% biodegradable, light weight and hyper efficient (more here); they will rival an American partnership with very similar goals (previous post).

And if ever we were to make the transition towards hydrogen fuelled vehicles, it is likely that the gas will be produced from biomass, which offers the most efficient and cleanest production pathway. According to a recent comprehensive well-to-wheel analysis of different propulsion concepts, hydrogen made from wood beats all other production methods when it comes to efficiency and cleanliness, including hydrogen from electrolysis of water power by wind energy, nuclear or fossil fuels (see here).

The most optimal use of biomass for transport, however, remains its conversion into electricity in efficient combined heat and power (CHP) or combined heat, power and cooling plants (CCHP), for use in battery electric cars - like Ravi's 'bio-car'.

References:

The Economic Times: NRI Globetrotter design wows global community - November 25, 2007.

Wheels: The Top Tree - Young Designer of the Year Award - November 1, 2007.

Inhabitat: GLOBETROTTER ECO CAR Wins Young Designer of the Year Award - December 4, 2007.

Biopact: Grow it yourself: the biodegradable, plant-based car is here - March 27, 2007

Biopact: Canadian universities receive C$6 million to build plant-based 'BioCars' - March 13, 2007

Biopact: U.S. universities teaming up to build 90% biodegradable car - March 01, 2007

Biopact: Hydrogen out, compressed biogas in - October 01, 2006

And there’s much more - a zinc-air fuel cell, nano-paper battery, airless tires, nanopaints to absorb solar energy while parked to charge its batteries, and natural fiber woven seat material. This car is lightweight, functional, frugal - the ultimate 'tread lightly' automotive feast for the environment-savvy consumer. If its batteries are charged with bio-electricity - the most efficient and cost-effective form of renewable energy - Ravi's concept becomes a fully carbon-neutral 'bio-car'. What's more, if it were to be powered by carbon negative electricity from biomass, the carbon dioxide of which is captured and sequestered, it could even take emissions out of the atmosphere!

Interestingly, the entire vehicle is 'designed-for-disassembly', a design philosophy based on the increasingly important 'cradle to cradle' concept, which makes designers think of how their products can be broken down and its individual parts reused in similar or totally different products. The bioplastic components conform to the idea as well, because when they are biodegraded in soils, they become nutrients for plants from which new bioplastics can be made - a perfectly closed loop that differs significantly from mere 'recycling'.

Harsha Ravi designed his first car at the age of 13. His childhood penchant for sketching people and landscapes finally earned him accolades when he was awarded the title of the Australian Young Designer of the Year, 2007, in October, for designing a futuristic car for 2017. The award has been instituted by the magazine Wheels in conjunction with the Australian Design Awards. It recognizes and rewards Australia’s outstanding young automotive designers:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioplastic :: biopolymer :: biocomposites :: negative emissions :: design-for-disassembly :: cradle-to-cradle ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioplastic :: biopolymer :: biocomposites :: negative emissions :: design-for-disassembly :: cradle-to-cradle :: Ravi, a Chennai-born NRI studying in Australia, is a part-time student at Monash University, Melbourne, Australia. He is pursuing a bachelor’s degree in Industrial/Product design at the university. His environment-friendly car, Globetrotter, was selected out of 17 entries at this year’s competition. The eight-judge panel included experts like GM Holden design director Antony Stolfo, Australian International Design Awards executive director Brandon Glen, Nielsen Design Associates managing director Sandy McNeil and Newcastle University industrial design head Graham Paver.

This year’s competition marked the 50th anniversary of the Fiat 500 and the designs were required to be 2+1, 500cc and 500 kg. The judging criteria included innovation, intelligence of design, visual impact and form, functionality, visual impact and form, functionality, originality, quality and design for manufacture and maintenance, ergonomics and semantics, safety and environmental considerations:

The award entitles him to a three-month internship of $50,000 at GMs North American design studio in 2008, where he would work with a team of international students on an advanced design project. He would also get a $15,000 trip to a major international motor show in 2008, funded by aXcess of Australia. The other designs that were highly commended at the competition were H500 by Tanveerul Islam and Roll up by Edwin Yi Yuan.

Biocomposites and bioenergy are becoming increasingly attractive to future mobility concepts. Earlier this year researchers at the University of Warwick presented their first environmentally-friendly racing car with tyres made from potatoes and brake pads from cashew nut shells - it runs on biofuels (previous post). Likewise, Canadian universities have teamed up to develop a car that is over 90% biodegradable, light weight and hyper efficient (more here); they will rival an American partnership with very similar goals (previous post).

And if ever we were to make the transition towards hydrogen fuelled vehicles, it is likely that the gas will be produced from biomass, which offers the most efficient and cleanest production pathway. According to a recent comprehensive well-to-wheel analysis of different propulsion concepts, hydrogen made from wood beats all other production methods when it comes to efficiency and cleanliness, including hydrogen from electrolysis of water power by wind energy, nuclear or fossil fuels (see here).

The most optimal use of biomass for transport, however, remains its conversion into electricity in efficient combined heat and power (CHP) or combined heat, power and cooling plants (CCHP), for use in battery electric cars - like Ravi's 'bio-car'.

References:

The Economic Times: NRI Globetrotter design wows global community - November 25, 2007.

Wheels: The Top Tree - Young Designer of the Year Award - November 1, 2007.

Inhabitat: GLOBETROTTER ECO CAR Wins Young Designer of the Year Award - December 4, 2007.

Biopact: Grow it yourself: the biodegradable, plant-based car is here - March 27, 2007

Biopact: Canadian universities receive C$6 million to build plant-based 'BioCars' - March 13, 2007

Biopact: U.S. universities teaming up to build 90% biodegradable car - March 01, 2007

Biopact: Hydrogen out, compressed biogas in - October 01, 2006

--------------

--------------

According to Wetlands International, an NGO, the Kyoto Protocol as it currently stands does not take into account possible emissions from palm oil grown on a particular type of land found in Indonesia and Malaysia, namely peatlands.

According to Wetlands International, an NGO, the Kyoto Protocol as it currently stands does not take into account possible emissions from palm oil grown on a particular type of land found in Indonesia and Malaysia, namely peatlands.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home