Illovo Sugar announces £100 million investment in Mali sugar, biomass and ethanol sector

South Africa's Illovo Sugar has announced that it has approved a £100 million (€140/$208 million) investment in the emerging sugar, biomass and ethanol sector in Mali, one of the world's poorest countries. The single project will by itself cover 10% of Mali's gasoline needs, supply electricity to thousands of the country's rural poor, eliminate sugar imports completely and meet growing demand for the foodstuff in the region.

South Africa's Illovo Sugar has announced that it has approved a £100 million (€140/$208 million) investment in the emerging sugar, biomass and ethanol sector in Mali, one of the world's poorest countries. The single project will by itself cover 10% of Mali's gasoline needs, supply electricity to thousands of the country's rural poor, eliminate sugar imports completely and meet growing demand for the foodstuff in the region.Associated British Foods plc (ABF), an international food, ingredients and retail group holds a 51% stake in Illovo Sugar. Illovo Sugar will hold a 70% stake in the investment of 1.4 billion rand for the construction of a new sugar mill, an ethanol plant and an electricity co-generation unit that will utilize waste biomass (bagasse) from sugar processing to generate 4MW of renewable, carbon-neutral electricity. The remaining stake will be held by the government of Mali and private investors.

Illovo will manage a Mali government-sponsored agricultural development plan to produce the 1.5 million tonnes of sugar cane per annum required to supply the new facility. The project is based on a 14,000 hectare cane-growing operation that will be managed on behalf of the government and with the local community.

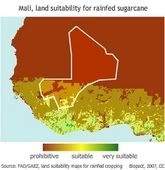

The project is vast in comparison to Mali's resource base. A Sahelian country, it currently produces less than 500,000 tons of sugarcane per year, primarily in the Southern region (map, click to enlarge). The Illovo project would by itself triple the entire country's output. Mali is a largely agricultural country, with over 80 per cent of its population making a living off the land. More than 60 per cent of all people there live under the poverty line.

Mali is fully dependent on oil imports. Luckily it only consumes around 4300 barrels per day of petroleum products, about half of which comes in the form of gasoline. Illovo's single ethanol plant would produce around 15 million liters per annum, thus roughly covering 10 per cent of Mali's total gasoline needs:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: bagasse :: molasses :: electricity :: sugar :: Mali ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: bagasse :: molasses :: electricity :: sugar :: Mali :: Sugar production at the new mill will begin in December 2009, reaching full capacity two years later. The factory will ultimately produce 200,000 tonnes of sugar per annum. Mali's own sugar production currently stands at around 30,000 tonnes per year, while demand is roughly 130,000 tonnes. The Illovo project will thus cover the entire country's sugar needs and supply regional markets.

The deal between the Malian government and Illovo took two years to negotiate and it covers everything from long-term labour relations, shift systems and the legality of foreign workers to repatriation of dividends, set prices for ethanol and electricity and the incorporation of ethanol into the country's fuel.

George Weston, Chief Executive of Associated British Foods, said that this investment in Mali follows Illovo’s recently announced expansion in Zambia.

Illovo Sugar's managing director Don MacLeod has adopted a cautious approach to ethanol production. It can take place only if government makes its production viable through incentives or taxes, and mandates its use in the fuel mix. For instance, in Brazil ethanol makes up 25% of the fuel mix and there is a 35% difference on the duties of petrol and ethanol, he says.

Unlike the production of biodiesel - which has the potential to drive up world food prices because it diverts food to fuel - the production of ethanol is not expected to drive sugar prices higher. That is because ethanol is produced from molasses, a non sucrose byproduct.

Illovo Sugar is the largest cane sugar producer in Africa and one of the world’s lowest cost producers. It is the leading producer in South Africa, Malawi, Zambia and Swaziland and has a strong and growing presence in Tanzania and Mozambique. It produced 1.7 million tonnes of sugar in the 2006/7 season and has development programmes to expand its capacity substantially.

Associated British Foods is a diversified international food, ingredients and retail group with sales of £6.8billion and 85,000 employees in 43 countries. It has significant businesses outside Europe in southern Africa, the US, China and Australia.

British Sugar is a substantial business within ABF. It has operations in the UK, Poland, China and southern Africa which process some 4 million tonnes of sugar annually. It is the most efficient sugar producer in Europe and has a proven ability to create value through improvement in agricultural yields, operational efficiencies, co-product development, marketing and product innovation. It has world class production facilities and technical expertise. The largest and most efficient beet sugar factory in the world is at Wissington in Norfolk and this is also the site for the UK’s first bioethanol plant.

British Sugar has four cane sugar mills in Guangxi province in southern China and sugar production exceeded 0.5 million tonnes in 2006/7. It announced on 24 August 2007 its first investment in the beet sugar industry in north east China.

References:

Associated British Foods: Illovo Sugar announces £100 million investment in Mali - November 22, 2007.

Financial Mail: Illovo Sugar Power projects - November 23, 2007.

--------------

--------------

SRI Consulting released a report on chemicals from biomass. The analysis highlights six major contributing sources of green and renewable chemicals: increasing production of biofuels will yield increasing amounts of biofuels by-products; partial decomposition of certain biomass fractions can yield organic chemicals or feedstocks for the manufacture of various chemicals; forestry has been and will continue to be a source of pine chemicals; evolving fermentation technology and new substrates will also produce an increasing number of chemicals.

SRI Consulting released a report on chemicals from biomass. The analysis highlights six major contributing sources of green and renewable chemicals: increasing production of biofuels will yield increasing amounts of biofuels by-products; partial decomposition of certain biomass fractions can yield organic chemicals or feedstocks for the manufacture of various chemicals; forestry has been and will continue to be a source of pine chemicals; evolving fermentation technology and new substrates will also produce an increasing number of chemicals.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home