CSIRO report on life cycle emissions of biodiesel in Australia confirms fuel cuts CO2, pollutants

A lifecycle analysis released today by Australia's Commonwealth Scientific and Industrial Research Organisation (CSIRO) confirms that using pure first generation biodiesel or blending biodiesel with standard fuel reduces greenhouse gas emissions and air pollutants from the transport sector.

A lifecycle analysis released today by Australia's Commonwealth Scientific and Industrial Research Organisation (CSIRO) confirms that using pure first generation biodiesel or blending biodiesel with standard fuel reduces greenhouse gas emissions and air pollutants from the transport sector.First generation biodiesel can be manufactured by transesterification of any product containing fatty acids, such as vegetable oil or animal fats. The report titled The greenhouse and air quality emissions of biodiesel blends in Australia [*.pdf] assesses the emission levels and environmental impacts of biodiesel produced from Australia's most common sources including used cooking oil, tallow (rendered animal fat), imported palm oil and canola.

CSIRO Energy Transformed National Research Flagship researcher and report author Dr Tom Beer believes the wider introduction of biodiesel in Australia would help address the high greenhouse gas intensity of Australia's transport sector. The results of the study show biodiesel has the potential to reduce emissions from the transport industry by up to 87%. The transport sector is the third largest producer of greenhouse gases in Australia, behind stationary energy generation and agriculture.

The greenhouse gas savings do however depend on the feedstock used to produce the biodiesel.

The upstream processes of growing and harvesting canola lead to upstream GHG emissions that are approximately 3.5 times higher than upstream emissions from refining the diesel. Tallow has upstream GHG emissions that are approximately 50% higher than the upstream emissions of diesel, whereas those of used cooking oil are slightly lower. Upstream GHG emissions of palm oil depend on whether the plantation was established before 1990, in which case the emissions associated with land clearing and with soil disturbance are not counted as greenhouse gas emissions under present methods of carbon accounting. In this case upstream greenhouse gas emissions are approximately 25% higher than the upstream emissions associated with diesel refining.

When using BD100 produced from tallow, canola, used cooking oil or plantation-based palm oil then the carbon dioxide emissions are offset by the carbon dioxide sequestered during the feedstock production so that the tailpipe GHG emissions are zero, which is to say that the emissions of fossil carbon are zero. However, fossil carbon or other greenhouse gases are emitted during the growth or manufacture of the feedstock.

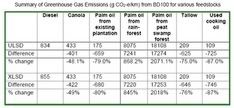

Overall this results in a saving in total life-cycle GHG emissions for different feedstocks: canola (422 g CO2-e/km saving; 49%), tallow (646 g CO2-e/km saving; 76%) used cooking oil (746 g CO2-e/km saving; 87%), palm oil from existing plantations (680 g CO2-e/km saving; 80%) when compared to extra low sulfur diesel (XLSD), which emits 855 g CO2-e/km. GHG emissions from palm oil that is sourced from cleared rain- or peat swamp forest are 8 to 21 times respectively greater than those from diesel. (table, click to enlarge).

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biodiesel :: lifecycle analysis :: greenhouse gas emissions :: Australia :: CSIRO ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biodiesel :: lifecycle analysis :: greenhouse gas emissions :: Australia :: CSIRO :: The extra upstream processing required for reducing the sulfur content results in higher GHG emissions for XLS diesel compared with ULS diesel. The highest savings in GHG emissions are obtained by replacing base diesel with biodiesel from used cooking oil (725 g CO2-e/km for ULSD to 746 g CO2-e/km for XLSD).

The large difference between the upstream emission of tallow and used cooking oil are

based on the assumption that the tallow is being taken from existing market uses and is not a waste product, whereas the used cooking oil is taken to be a true waste, with no existing market. If low-grade tallow, with no other viable markets, was available, its emission profile would be similar to that of used cooking oil. However, low-grade tallow does require more processing to produce biodiesel than high-grade (edible) tallow.

Blends with 2% biodiesel lead to much smaller GHG savings (when there are savings) or

much smaller increases (when there are increases): the savings are 14-15 g CO2-e/km for used cooking oil blends when using BD2 compared with diesel; 12-13 g CO2-e/km for

tallow biodiesel; and 7-8 g CO2-e/km for canola oil biodiesel. Palm oil based BD2 produces savings of 12-13 g CO2-e/km if the palm oil comes from existing plantations, but can lead to increases in GHG emissions that range from 142 to 338 g CO2-e/km if the palm oil comes from cleared rainforest or cleared peat swamp forest respectively.

Obviously not all new palm oil plantations are established on peat lands - the report looked at these specifically, because some environmentalists have made a case of this. The peat swamp issue is specific to a small region in Indonesia. New palm oil plantations in Africa and South America will have very different properties and result in fuels with a much lower carbon footprint. Transporting palm oil in ocean-going tankers is a very efficient transport mode, releasing very small emissions.

If palm oil was to be grown in Australia (rather than imported from Asia), the emissions are likely to increase further because of the greater use of mechanisation in Australian agriculture, with its concomitant increase in greenhouse gas emissions.

The use of biodiesel also reduces the particulate matter released into the atmosphere as a result of burning fuels, providing potential benefits to human health. Life-cycle emissions of CO, NMVOC, and particles are reduced when biodiesel blends are used, but emissions of NOx may increase slightly.

While the results are encouraging, further research is required to establish the viability of the biofuels industry in Australia and address some of the associated issues such as sustainability, technological improvements and economic feasibility.

CSIRO, as part of the Energy Transformed National Research Flagship, is undertaking an extensive research program into alternative fuels such as biodiesel to assess possible biophysical, social and economic impacts of their production and adoption.

References:

CSIRO: The greenhouse and air quality emissions of biodiesel blends in Australia [*.pdf] - November 27, 2007.

CSIRO: Alternative transport fuels: prospects and impacts.

--------------

--------------

SRI Consulting released a report on chemicals from biomass. The analysis highlights six major contributing sources of green and renewable chemicals: increasing production of biofuels will yield increasing amounts of biofuels by-products; partial decomposition of certain biomass fractions can yield organic chemicals or feedstocks for the manufacture of various chemicals; forestry has been and will continue to be a source of pine chemicals; evolving fermentation technology and new substrates will also produce an increasing number of chemicals.

SRI Consulting released a report on chemicals from biomass. The analysis highlights six major contributing sources of green and renewable chemicals: increasing production of biofuels will yield increasing amounts of biofuels by-products; partial decomposition of certain biomass fractions can yield organic chemicals or feedstocks for the manufacture of various chemicals; forestry has been and will continue to be a source of pine chemicals; evolving fermentation technology and new substrates will also produce an increasing number of chemicals.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home