Carbon-negative bioenergy recognized as Norwegian CO2 actors join forces to develop carbon capture technologies

Great news for the bioenergy community: carbon-negative biomass energy is beginning to penetrate the minds of some leading energy and engineering companies as well as scientists. Norway's SINTEF (Scandinavia's largest independent research organisation), Aker Kværner (a leading energy engineering firm), and the Norwegian University of Science and Technology (NTNU) have announced they are to cooperate on the development of new amine based CO2 capture technologies. The scientists say the new agreement could produce cuts in emissions that would make a real difference on a global scale. They explicitly focus part of their research on capturing flue gases from biomass power plants, which opens the era of carbon-negative energy.

Great news for the bioenergy community: carbon-negative biomass energy is beginning to penetrate the minds of some leading energy and engineering companies as well as scientists. Norway's SINTEF (Scandinavia's largest independent research organisation), Aker Kværner (a leading energy engineering firm), and the Norwegian University of Science and Technology (NTNU) have announced they are to cooperate on the development of new amine based CO2 capture technologies. The scientists say the new agreement could produce cuts in emissions that would make a real difference on a global scale. They explicitly focus part of their research on capturing flue gases from biomass power plants, which opens the era of carbon-negative energy.The institutions compare their efforts to a Norwegian version of the Apollo Program. They have received support from the Norwegian state, which is investing part of its oil & gas money into the project, and massive backing from the Norwegian Industry employers organisation, the Norwegian Federation of Trade Unions and the country's environmental organisations. The market for CO2 capture technologies is potentially so large, that a one percent share would mean a turnover of NOK 240 billion (€30.9/US$44.2 billion) by 2100, which is why Norwegian society would be well repaid for these investments.

We have written extensively about so-called 'bio-energy with carbon storage' (BECS) systems, which consist of capturing and sequestering the carbon not from coal and gas, but from biomass used in power stations and fuel production plants (more here). Scientists who developed the BECS concept within the context of 'abrupt climate change' scenarios, see it as one of the few realistic geo-engineering options to reduce greenhouse gas emissions drastically and globally. If negative emissions systems were to be implemented on a global scale, we could bring back atmospheric CO2 levels to pre-industrial levels by mid-century and largely prevent the potentially catastrophic impacts of climate change.

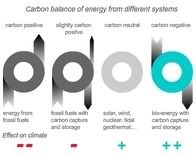

Carbon-negative energy can only be obtained from biofuels and biomass. Renewables like solar, wind or even nuclear power are all 'carbon-neutral' in theory, slightly 'carbon-positive' in practise (schematic, click to enlarge). That is, over their lifecycle they add few or no emissions to the future. But this may be too weak an offer as global emissions are growing more rapidly than expected and are already exceeding the IPCC's worst-case scenario (earlier post). This means we will need energy systems that can begin to capture and remove emissions from the past. BECS systems do exactly that: as biomass grows, it takes CO2 out of the atmosphere; if this carbon-neutral fuel is combusted and its carbon emissions captured and then locked up permanently, we have a system that takes historic emissions out of the atmosphere. In short, most renewables prevent new emissions from occuring, but BECS systems effectively clean up our dangerous and dirty past.

For BECS systems to become feasible two main developments are in order: an efficient global biomass market will have to emerge which will require the establishment of vast energy plantations with high yielding biomass crops which act as carbon capture machines, planted at strategic locations (hence the 'geo-engineering' label), and secondly, efficient and cost-effective carbon capture technologies will have to be engineered.

The Norwegian research agreement will focus on the latter, important need. A central aspect of their cooperation is a plan for SINTEF and NTNU to develop and test more efficient chemicals - amine mixtures - for scrubbing CO2 from flue gases. The chemicals will be specially adapted to Aker Kværner’s concept for CO2 capture from coal- and gas-fired power stations, which is called 'Just Catch' technology. This technology will be able to reduce emissions by up to 90%. However, for the revolutionary carbon-negative bioenergy power systems, the company is developing 'Just Catch Bio'.

Breaking a monopoly

Nils Røkke, director of gas technology research at SINTEF, and Hallvard Svendsen, a professor of chemistry at NTNU, say that by signing a contract with Aker Kværner on the chemical side, they are helping to qualify the company to supply CO2 capture plants to the world market, on which there is virtually a monopoly today. With its cost-effective technology the Norwegian company will be able to force prices down and ensure that CO2 capture is adopted more rapidly:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture :: bio-energy with carbon storage :: carbon-negative :: climate change :: Norway ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: carbon capture :: bio-energy with carbon storage :: carbon-negative :: climate change :: Norway :: The calculations made by SINTEF and NTNU show that the world will need about 7,500 capture plants for coal- and gas-fired power stations by 2100, as well as greater use of biomass, and more efficient energy utilisation, if we are to prevent the world’s annual mean temperature from rising by more than two degrees.

According to figures from SINTEF and NTNU, annual cuts in the CO2 emitted by 2.5 percent of these plants would be equivalent to total current Norwegian CO2 emissions as well as the annual CO2 emissions produced by our oil and gas exports at present.

Røkke and Svendsen believe that the potential for Norwegian industry to make a contribution to efficient CO2 capture technology is not being paid enough attention in the national debate about environmental matters. “Of course we should also be implementing measures that will reduce this country's own emissions. But it is as a technology supplier on the world market that Norway can contribute to CO2 cuts that will make a difference on a global scale,” say the two.

Scrubbing flue gases

Today, only a few international companies are capable of supplying plants that capture CO2 from coal- and gas-fired power stations. These are solutions that are based on 'scrubbing' CO2 out of the stations’ flue gases, using water-soluble chemicals called amines.

SINTEF and NTNU are to develop similar and alternative chemicals for Aker Kværner in the course of the new cooperation agreement. The plan is to develop new chemical systems that will be more efficient, more stable and less damaging to nature than the amines in current use.

We have a very good point of departure. Thanks to strategic long-term research funding from the Research Council of Norway and Gassnova, as well as our participation in several EU projects, we have built up a high level of expertise in this field at SINTEF and NTNU. We have sown a lot of seed, which we hope will contribute to what we see as Norway’s equivalent of the USA’s moon landing, and our vision of Norwegian technology leadership in climate technology.- Nils Røkke and Hallvard SvendsenSpin-off chemical company

The agreement signed with the two reseach institutions and Aker Kværner includes plans for establishing a jointly owned company that will own the rights to the new chemical systems and sell them to Aker Kværner and other users.

The agreement also includes plans for further expansion of the laboratories that SINTEF and NTNU use in their CO2 capture research. This will strengthen the global toolbox for developing efficient, new and cheap climate technologies, claim the two research institutions.

SINTEF and NTNU have also been estimating the value of a future market for CO2 capture plants. The point of departure for their calculations is that around 7500 such plants could be constructed by 2100.

A one percent share of such a market would mean a turnover of NOK 240 billion (€30.9/US$442 billion) by 2100, so Norwegian society would be well repaid for its investments in research in this field, say Røkke and Svendsen.

The 'Just Catch' technology

Aker Kværner has been developing its own CO2 capture technology since 1991, and has been an active driving force behind efforts to develop new green power generation solutions. In 2005, the company decided to go in for Just Catch technology in a big way. Aker Kværner has established a major development project in collaboration with 12 industrial partners and Gassnova.

That project has enabled the company to identify several technical improvements that would be capable of reducing both the construction and operating costs of such CO2 capture plants, says Oscar Fredrik Graff, gas technology director at Aker Kværner.

According to Graff, the technical improvements identified by the company can be summarised as follows:

- Development and testing of optimum amine mixtures for different CO2sources

- Efficient integration of heat into the process

- Selection of new types of pumps and heat exchangers

- More compact and efficient plants

- Minimising the environmental impact of the plant.

Great expectations

In the course of the past six months the company has considered a number of different partners in amine development. It analysed several international players in this field, and finally came to the conclusion that SINTEF and NTNU could offer the best support in this task. Choosing the best amine mixture is vital in plants of this sort. The right choice will offer stable operating conditions, and reduce energy requirements and other operating costs.

Aker Kværner already has around 40 engineers working on the development of the 'Just Catch' technology, in addition to partners and other suppliers engaged by the company.

Carbon-negative bioenergy: 116% scrubbing

Aker Kværner is developing a special version of its 'Just Catch' technology that uses biomass to produce the energy needed for CO2 capture.

The scrubbing plant would normally use energy from the power station. By scrubbing both the power station’s flue gases and those from the bio-energy plant, the scrubber will also remove 'natural' CO2, that is the CO2 that the woody biomass fuel would otherwise have released in the course of its natural breakdown. This solution, known as 'Just Catch Bio', is thus potentially capable of removing 116% of the CO2 emissions from a gas-fired power station.

This is only the first step towards full blown BECS systems, because the 'Just Catch Bio' capture technology can be further modified to work on power plants that run entirely on biomass. Over their entire lifecycle - including the production of the biomass fuels -, such carbon-negative energy systems may produce energy which removes up to 150 per cent of CO2 (see the Abrupt Climate Change Strategy group's analyses of BECS).

One advantage of 'Just Catch' technologies is that they can be retrofitted to existing power stations, including biomass plants. If the cuts in CO2 emission that many countries are aiming for are to have any credibility, they will require flue gases from existing plants to be scrubbed on a large scale. This will open up a large market for this technology, says Graff.

The 'Just Catch' technology can be adapted to be utilized on a wide range of sources of CO2, such as those from gas- and coal-fired power stations, biomass, refineries and the cement industry.

Schematic: credit Biopact, CC.

References:

SINTEF: Norwegian CO2 actors join forces - October 24, 2007.

Aker Kværner: Just Catch technology.

Biopact: Growth in carbon emissions accelerating; exceeding worst case scenario - October 23, 2007

Biopact: A quick look at 'fourth generation' biofuels - October 08, 2007

Euractiv: 'Carbon-capture trials safest way forward' - Laurens Rademakers, Biopact - April 3, 2007.

Abrupt Climate Change Strategy group: overview of studies on carbon-negative bioenergy and its potential to reduce atmospheric CO2 levels.

--------------

--------------

Ethablog's Henrique Oliveira, a young Brazilian biofuels business expert, is back online. From April to September 2007, he traveled around Brazil comparing the Brazilian and American biofuels markets. In August he was joined by Tom MacDonald, senior alcohol fuels specialist with the California Energy Commission. Henrique reports about his trip with a series of photo essays.

Ethablog's Henrique Oliveira, a young Brazilian biofuels business expert, is back online. From April to September 2007, he traveled around Brazil comparing the Brazilian and American biofuels markets. In August he was joined by Tom MacDonald, senior alcohol fuels specialist with the California Energy Commission. Henrique reports about his trip with a series of photo essays.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home