Carbon-negative bioenergy is here: GreatPoint Energy to build biomass gasification pilot plant with carbon capture and storage

The transition towards radically carbon-negative energy is happening faster than expected. Today, GreatPoint Energy, Inc., a developer of technology to convert coal, petroleum coke and biomass into clean natural gas while enabling the capture and sequestration of CO2, announced plans to build a US$25 million pilot-scale gasification plant to be located in Brayton Point at the research and development center of energy utility Dominion. Dominion is the largest power generating facility in New England. GreatPoint Energy has secured a grant from the Massachusetts Technology Collaborative to test biomass in its facilities.

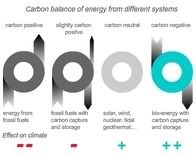

The transition towards radically carbon-negative energy is happening faster than expected. Today, GreatPoint Energy, Inc., a developer of technology to convert coal, petroleum coke and biomass into clean natural gas while enabling the capture and sequestration of CO2, announced plans to build a US$25 million pilot-scale gasification plant to be located in Brayton Point at the research and development center of energy utility Dominion. Dominion is the largest power generating facility in New England. GreatPoint Energy has secured a grant from the Massachusetts Technology Collaborative to test biomass in its facilities.By coupling biomass gasification to carbon capture and storage (CCS), yet another step towards carbon-negative bioenergy systems is being taken - the most effective type of energy with which to reduce greenhouse gas emissions and combat climate change (earlier post and here). The plant in Massachusetts will use wood chips, corn stover, and switchgrass as a feedstock to make natural gas. These biomass sources store CO2 from the atmosphere. When they are gasified they release CO2, which is then captured and sequestered permanently in geological sites. The end balance: negative emissions. Only energy systems based on biomass can become carbon-negative - that is, they take emissions from the past out of the atmosphere. All other renewables are carbon-neutral at best, slightly carbon-positive in practise (previous post; and schematic, click to enlarge).

GreatPoint has developed a technique for converting different feedstocks - coal, petroleum coke, or biomass - into methane, or natural gas, through a catalyst-based gasification process - the 'bluegas' process. It says this allows it to produce natural gas that costs less than current market prices, while at the same time the process can be easily coupled to CCS. This combination of factors has attracted the attention of top-flight venture capitalists and other industrial companies. Last month, it announced an additional $100 million investment led by Dow Chemical, Suncor Energy, AES, and Citi division Sustainable Development Investments (earlier post).

The bluegas gasification system is an optimized catalytic process for combining coal, steam and a catalyst in a pressurized reactor vessel to produce pipeline-grade methane (99 percent+ CH4) instead of the low quality syngas produced by conventional gasification shown below. The first step in the bluegas process is to feed the coal or biomass and the catalyst into the methanation reactor. Inside the reactor, pressurized steam is injected to 'fluidize' the mixture and ensure constant contact between the catalyst and the carbon particles. In this environment, unlike conventional gasification, the catalyst facilitates multiple chemical reactions between the carbon and the steam on the surface of the coal or biomass. These reactions catalyzed in a single reactor generate a mixture predominately composed of methane and CO2 (schematic, click to enlarge):

The bluegas gasification system is an optimized catalytic process for combining coal, steam and a catalyst in a pressurized reactor vessel to produce pipeline-grade methane (99 percent+ CH4) instead of the low quality syngas produced by conventional gasification shown below. The first step in the bluegas process is to feed the coal or biomass and the catalyst into the methanation reactor. Inside the reactor, pressurized steam is injected to 'fluidize' the mixture and ensure constant contact between the catalyst and the carbon particles. In this environment, unlike conventional gasification, the catalyst facilitates multiple chemical reactions between the carbon and the steam on the surface of the coal or biomass. These reactions catalyzed in a single reactor generate a mixture predominately composed of methane and CO2 (schematic, click to enlarge): energy :: sustainability :: biomass :: bioenergy :: biofuels :: climate change :: gasification :: carbon capture and storage :: bioenergy with carbon storage :: carbon negative ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: climate change :: gasification :: carbon capture and storage :: bioenergy with carbon storage :: carbon negative :: The proprietary catalyst formulation is made up of abundant, low cost metal materials specifically designed to promote gasification at the low temperatures where water gas shift and methanation take place. The catalyst is continuously recycled and reused within the process.

As part of the overall process the bluegas production facility recovers most of the contaminants in coal as useful by-products and, in addition, roughly half the carbon in the coal is captured as a pure CO2 stream suitable for sequestration.

In addition, unlike many conventional gasifiers, the bluegas process is ideally suited for lowest cost feedstocks such as Powder River Basin (“PRB”) coal and petroleum coke from the Canadian oil sands (a waste-product produced in the upgrading process) as well as a number of biomass feedstocks. The result is a disruptive technology with dramatically improved economics and an environmental footprint equivalent to that of natural gas, the most environmentally-friendly fossil fuel.

GreatPoint Energy and Dominion will be hosting a ceremony today with Governor Deval Patrick to commemorate the agreement in Somerset, Massachusetts. GreatPoint Energy plans to create more than 100 new jobs and invest more than $25 million in the demonstration plant and R&D Center of Excellence.

Upon the completion of construction of the demonstration plant and research complex, which is expected to take twelve months, GreatPoint Energy intends to develop full-scale facilities around North America. The company will then transport its bluegas product to New England residents by pipeline at a cost that is less than drilled or imported natural gas.

GreatPoint Energy plans to locate its commercial gasification facilities in locations where the carbon removed from the biomass and fossil fuel feed can be sequestered in geological formations or used for enhanced oil recovery.

References:

GreatPoint Energy to Build Leading-Edge Research Center and Clean Energy Demonstration Plant at Dominion's Brayton Point Power Station in Somerset, Mass. - October 25, 2007.

Biopact: GreatPoint Energy closes $100 million capital raise for gasification and CCS technology - September 24, 2007

Biopact: Growth in carbon emissions accelerating; exceeding worst case scenario - October 23, 2007

Biopact: A quick look at 'fourth generation' biofuels - October 08, 2007

Euractiv: 'Carbon-capture trials safest way forward' - Laurens Rademakers, Biopact - April 3, 2007.

Abrupt Climate Change Strategy group: overview of studies on carbon-negative bioenergy and its potential to reduce atmospheric CO2 levels.

--------------

--------------

U.S. oil prices and Brent crude rocketed to all-time highs again on a record-low dollar, tensions in the Middle East and worries over energy supply shortages ahead of the northern hemisphere's winter. Now even wealthy countries like South Korea are warning that the record prices will damage economic growth. In the developing world, the situation is outright catastrophic.

U.S. oil prices and Brent crude rocketed to all-time highs again on a record-low dollar, tensions in the Middle East and worries over energy supply shortages ahead of the northern hemisphere's winter. Now even wealthy countries like South Korea are warning that the record prices will damage economic growth. In the developing world, the situation is outright catastrophic.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home