Yulex partners with USDA and Mendel Biotech to double rubber and biomass yields of Guayule

Yulex Corporation, the United States Department of Agriculture’s Agricultural Research Service (USDA-ARS), and Mendel Biotechnology have signed an agreement to develop and field test proprietary Guayule plants with enhanced natural rubber latex yields and increased biomass.

Yulex Corporation, the United States Department of Agriculture’s Agricultural Research Service (USDA-ARS), and Mendel Biotechnology have signed an agreement to develop and field test proprietary Guayule plants with enhanced natural rubber latex yields and increased biomass.Yulex Corporation is at the forefront of a clean technology industry in the U.S. Southwest based on Guayule (Parthenium argentatum), a versatile desert plant that has become a commercial source of bio-based rubber latex, and a cellulosic feedstock for bioethanol and other forms of bioenergy production.

With record oil prices, raw material costs for the manufacture of many rubber products have increased substantially. Both natural rubber (from Hevea trees) as well as synthetic rubber have trended up steeply, partly as a result of high petroleum prices, but strong demand from rapidly growing economies (especially China) is a key factor too (graph, click to enlarge). This situation has revived interest in alternative plants that yield latex. Guayule has been intensively researched as a candidate for almost a century.

With record oil prices, raw material costs for the manufacture of many rubber products have increased substantially. Both natural rubber (from Hevea trees) as well as synthetic rubber have trended up steeply, partly as a result of high petroleum prices, but strong demand from rapidly growing economies (especially China) is a key factor too (graph, click to enlarge). This situation has revived interest in alternative plants that yield latex. Guayule has been intensively researched as a candidate for almost a century. Launching this program with Mendel and the Agricultural Research Service will greatly accelerate the achievement of our long term goals which include the ability to provide an economical rubber product on a global basis while providing a regional solution for ethanol production in the Southwest United States. We expect to see a vast improvement in guayule rubber yields which will allow guayule production fields to produce significantly more rubber per acre than rubber plantations in Southeast Asia. - Jeffrey Martin, CEO and President of Yulex CorporationRobert A. Creelman, senior scientist at Mendel Biotechnology and principle investigator on the project says that expertise in plant regulatory genes and proprietary technology in transferring these genes, must allow for the creation of improved varieties of guayule that will make twice as much rubber. Since guayule grows in the United States, these improved varieties will create opportunities for American farmers, reduce dependence on imported natural latex and rubber, and decrease use of synthetic latex and rubber.

The goal of collaboration is to increase the amount of latex, rubber, and biomass the plant produces. Over the next three years, Yulex Corporation, Mendel Biotechnology, and USDA scientists will test the new guayule transgenic lines and enhanced rubber biosynthesis genes for yield improvements as well as stress tolerance. Yulex will conduct latex extraction and chemical tests, the USDA-ARS will perform agronomic, chemical and biochemical tests, and Mendel will carry out molecular tests on the new transgenic guayule plants:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: rubber :: latex :: Hevea :: Guayule :: biotechnology ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: ethanol :: rubber :: latex :: Hevea :: Guayule :: biotechnology :: Yulex obtained an exclusive license on a technology developed by Agricultural Research Service scientists in 1997 to extract natural rubber latex from the guayule plant. Since then, Yulex has emerged as the market innovator producing medical grade latex for medical and consumer products.

Yulex is currently marketing its high-performing natural rubber latex material to medical device manufacturers internationally in order to provide needed alternative products for the 73 percent of spina bifida children that suffer from Type I latex allergy and the 10 percent of healthcare workers and six percent of the general population that have symptoms of latex allergy.

The crop

Guayule grows to an average height of three feet, and produces natural rubber latex in its bark. The "variety protected" line of domesticated Guayule, reaches maturity in two years with high-latex yields.

Guayule grows to an average height of three feet, and produces natural rubber latex in its bark. The "variety protected" line of domesticated Guayule, reaches maturity in two years with high-latex yields.For sustainable production, guayule grows well in arid and semi arid areas of the southwestern United States, North Central Mexico and regions with similar climates around the world. Because the Guayule plant produces terpene resins, which are natural pesticides, it is resistant to many pests and diseases. Herbicides are primarily necessary for stand establishment. When ready for harvest, it is clipped and baled with patented farming equipment. After clipping, Guayule will re-grow from its root system and be ready for latex harvesting again year after year.

Guayule has a century's worth of history as an American rubber source and alternative to the tropical Brazilian rubber tree; however, previous efforts had focused on bulk rubber for the tire industry. Yulex is the first commercial enterprise to develop Guayule as an industrial crop for its valuable latex which is marketed to the medical device industry and other.

Extracting latex

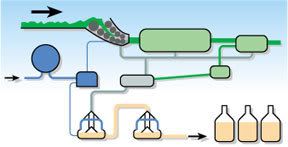

Yulex is the first company to commercially extract latex from Guayule. The patented manufacturing process Yulex uses is economical as well as environmentally sound. The Yulex biorefinery is fully automated 24/7 and produces medical-quality natural rubber latex, bio-based materials such as cellulosic ethanol, adhesives, organic pesticides, wood preservatives and other specialty chemicals.

Yulex is the first company to commercially extract latex from Guayule. The patented manufacturing process Yulex uses is economical as well as environmentally sound. The Yulex biorefinery is fully automated 24/7 and produces medical-quality natural rubber latex, bio-based materials such as cellulosic ethanol, adhesives, organic pesticides, wood preservatives and other specialty chemicals.Yulex's commercial pilot operation is located in Phoenix, Arizona. The bioprocessing operations extract the natural rubber latex from the Guayule biomass utilizing environmentally friendly ("green") processing, using only aqueous (water-based) solution.

The extraction process follows a patented four step operation which includes grinding, filtration, clarification, and concentration. The process begins with homogenizing the Guayule plant. Branches are ground breaking open the cells in the plant, releasing intact rubber particles and creating an aqueous suspension (forming latex). The suspension is placed in a high-speed centrifuge for separation and Guayule rubber particles are lighter than the aqueous solution, they are separated from the suspension. The latex portion of the mixture is culled off the top (much the same way that cream is skimmed off milk) and purified. Yulex latex is then shipped to the company's distribution and manufacturing partners.

Photo opening the article: Guayule latex is milky white after processing. Credit: David Kadlubowski, Yulex Corporation

--------------

--------------

Brasil Ecodiesel, the leading Brazilian biodiesel producer company, recorded an increase of 57.7% in sales in the third quarter of the current year, in comparison with the previous three months. Sales volume stood at 53,000 cubic metres from August until September, against 34,000 cubic metres of the biofuel between April and June. The company is also concluding negotiations to export between 1,000 to 2,000 tonnes of glycerine per month to the Asian market.

Brasil Ecodiesel, the leading Brazilian biodiesel producer company, recorded an increase of 57.7% in sales in the third quarter of the current year, in comparison with the previous three months. Sales volume stood at 53,000 cubic metres from August until September, against 34,000 cubic metres of the biofuel between April and June. The company is also concluding negotiations to export between 1,000 to 2,000 tonnes of glycerine per month to the Asian market.

3 Comments:

Blessings:

Sort of funny that HEMP/Cannabis is still against the LAW considering it was known as the brightest burning oil for centuries and FORD designed his first cars to run on a hemp-based bio-mass fuel.

Considering it has the ability to help solve world hunger, can also be used medicinally for enourmous amounts of illnesses, including BOTH cancer and heart disease.

Sort of funny it was pressure from the United States that made it illegal in the first place just a few decades ago.

Kinda funny and totally EVIL how people follow these liars to their doom despite the FACTS shown them.

your humble servant,

ancient clown

Good post.

[email protected]

To learn more about the guayule industry, a new report is available providing readers with the latest information about the industry. Visit www.guayuletech.com

Post a Comment

Links to this post:

Create a Link

<< Home