Microbial fuel cell development speeds up: from biopower in space to the developing world

A few days ago a team of MIT materials science students won first prize in the inaugural MADMEC (MIT and Dow Materials Engineering Contest) with a microbial fuel cell (MFC) that efficiently converts cellulosic biomass into electricity. And in this week's issue of Journal of Power Sources, biological engineers at Oregon State University report they designed an MFC that is capable of generating about 10 times more electricity than previously possible from an air cathode microbial fuel cell of the same size. This presents an occasion to focus on the concept a bit more in depth.

Recent design breakthroughs and efficiency leaps have taken microbial fuel cells out of their experimental status and ready to be used in concrete applications. The devices can clean waste water and deliver renewable energy while doing so. In principle they can be fed virtually any type of biomass, from rotten fruit and cellulose to algae and mosquitos. Electronic gadgets are already being powered by MFCs (earlier post). And thanks to self-sustaining microbial fuel cells, robots could soon perform difficult tasks fully autonomously by feeding on... flies. More importantly, scientists think biological fuel cells will revolutionize energy generation in space, but also in the developing world.

A bio-battery or microbial fuel cell converts chemical energy, available in an organic substrate, directly into electricity. To achieve this, bacteria are used as a catalyst to convert substrate into electrons. The micro-organisms can convert a huge variety of organic compounds into CO2, water and energy. They use the produced energy to grow and to maintain their own metabolism. However, by using a MFC we can harvest a part of this microbial energy in the form of electricity.

The electrons then flow through an electrical circuit with a load or a resistor to the cathode. The potential difference (Volt) between the anode and the cathode, together with the flow of electrons (Ampere) results in the generation of electrical power (Watt). The protons flow through the proton or cation exchange membrane to the cathode. At the cathode, an electron acceptor is chemically reduced. Idealy, oxygen is reduced to water. To obtain a sufficient oxygen reduction reaction (ORR) rate a platina-catalyst is sometimes used. However, many researchers have meanwhile developed non-noble metal catalysts.

MFCs can be very large, several cubic meters by volume, or extremely small. Just like ordinary batteries, they can be coupled in series or in parallel. Until recently their energy density remained quite low. But major efficiency leaps are being made.

Efficiency breakthrough

In this week's issue of Journal of Power Sources, biological engineers at Oregon State University report they designed a microbial fuel cell that is capable of generating about 10 times more electricity than previously possible from an air cathode microbial fuel cell of the same size.

This design breakthrough could allow microbial fuel cells to be used more widely as sources of sustainable energy, says Hong Liu, lead author and assistant professor in the OSU Department of Biological and Ecological Engineering.

The new design could ultimately lead to portable systems for power generation that are simultaneously capable of providing reusable water for developing nations and remote areas. The fuel cell design could also significantly reduce the amount of electricity used at large wastewater treatment facilities.

The new design, developed with fellow OSU professor Yanzhen Fan and OSU graduate student Hongqiang Hu, involves sandwiching a cloth layer between the anode and the cathode parts of the microbial fuel cell, a configuration that greatly reduces the internal resistance, resulting in a much higher power density, Liu says.

In lab experiments, Liu’s team successfully generated 1,010 watts per cubic meter of reactor, or enough to power 16 60-watt light bulbs. The highest previous level of sustainable electricity generated from a cubic meter of air cathode microbial fuel cell is less than 115 watts. In experiments done even more recently, Liu and colleagues have generated more than 1,500 watts from the same reactor volume:

energy :: sustainability ::biomass :: bioenergy :: biofuels :: cellulose :: microbial fuel cell :: biofuel cell :: bio-battery :: decentralisation :: efficiency ::

energy :: sustainability ::biomass :: bioenergy :: biofuels :: cellulose :: microbial fuel cell :: biofuel cell :: bio-battery :: decentralisation :: efficiency ::

The design improvements could eventually lead to a dramatic reduction in the cost of operating wastewater treatment plants in the U.S. and elsewhere. Five percent of the electricity in the U.S. is used for water and wastewater treatment, mainly to power pumps and other equipment. By incorporating microbial fuel cells in water treatment facilities, the cost of operation could be reduced, Liu says.

Although scaling up microbial fuel cells to help power large wastewater facilities is a long-term goal of Liu’s, she says small scale systems for households in the developing world will be feasible sooner.

Liu’s research is supported in part by a $200,000 grant from the U.S. Department of Transportation through the Sun Grant Initiative, the OSU General Research Fund and the OSU Agricultural Research Foundation (earlier post on this interesting funding initiative that aims to kickstart the bioeconomy).

Across the world, biomass materials are currently utilized in vastly inefficient combustion processes (open fires) that lead to harmful smoke pollution and have become a primary factor in respiratory infections. Indoor smoke pollution kills an estimated 2 million women and children each year. Efficient and cost-effective MFCs could prompt households to use other types of biomass instead of wood, and switch to an electric future. This would solve a major health crisis and save forests.

Bio-power in space

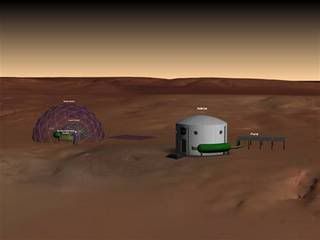

The good thing about MFCs is that some of the world's top scientists in the space industry are working on them too, in futuristic settings. NASA researchers think they could power future space habitats (like a Mars base), because they are far more flexible than existing power systems. Their research could find applications in some of the poorest regions here on Earth.

The multiple advantages of biology's mechanisms become apparent when you take things to their extreme - to space. Traditional systems for making electricity in space depend on the hardest of hardware: photovoltaics (solar panels), hydrogen fuel cells, radioisotope thermal generators. These need to be 'manufactured' and hauled along. At a meeting of the NASA Institute for Advanced Concepts (NIAC) last fall, Matthew Silver, a space systems engineer who heads IntAct Labs in Cambridge, Mass., presented radical ideas for using biology and bioenergy instead, in a new generation of power supplies.

Unlike the older systems, the proposed devices would be 'grown' instead of 'manufactured'. They generate electrons using microbes that live in mud, or proteins native to the human ear or in photosynthetic bacteria. They would feed on carbohydrates contained in biomass that can readily be produced, stored and handled. In short, they would make the old science fiction concept of the 'carbohydrate economy' a reality.

In theory, biological power systems offer a number of advantages. Existing systems such as solar panels are based on physical and chemical processes that are difficult and costly to manufacture, and difficult to modify once fabricated. Biological systems may offer a high power-to-weight ratio, convenient fuel storage and many of them make useful byproducts like molecular oxygen. But the ultimate promise is this: they might be grown on demand, in space.

Basing a fuel cell on microbes offers many theoretical advantages over the hydrogen or methane fuel cell, Lovley says. "A catalyst is not needed, and catalysts are normally expensive and easily fouled." A second advantage comes from the mucky nature of the fuel itself. "The fuel doesn't have to be clean," says Lovley. "It can actually be dirt, or waste products."

As Silver envisions it, a microbial fuel cell could digest human waste and other organic garbage during a trip to Mars. NASA's Waste Processing and Resource Recovery Workshop estimated that a crew of six would, on a low-carb diet, produce 10.55 kilograms of organic waste per day en route to Mars. That quantity of waste, Silver calculates, could produce up to about 1 kilowatt of constant power in a microbial fuel cell. NASA has estimated that life support systems on such a craft would need roughly 1 kilowatt per person during a cruise to Mars.

The carbon dioxide produced by bacterial oxidization of organic waste could be used to grow 'crops' in sunlit chambers, producing molecular oxygen as a byproduct. The feedstock could be algae or other carbohydrate containing plants, that could then be used to feed the microbial fuel cell and make more electricity. A similar process could create electricity on Mars.

While prototype microbial fuel cells have used a single strain of microbe, multiple organisms could increase the power output, particularly if the input were organic wastes. "We presented to NIAC the fact that different bacteria metabolize different things," says Silver. "A microbial fuel cell could use cascading chambers," where the output of one cell becomes the feedstock for a successive cell. For example, when bacteria in the genus Clostridium metabolize sugar, they do not use all the energy available in the sugar. Geobacter, however, can metabolize the waste products of some Clostridium, Silver suggests. Even better, Silver adds, through genetic engineering, "a novel organism could be designed that digests a greater range of inputs."

Using organic material as fuel leads to another advantage of microbial fuel cells for space exploration: organic matter is easy to store. While electricity from a photovoltaic panel must be stored in massive batteries or another complicated storage system, storage requirements for bacterial power units would be minimal, because the microbes could be fed to generate electricity as needed.

Another potential advantage of biological power systems is their "homegrown" potential. The complex material conversions needed to manufacture the power systems could be performed by microorganisms; they would not require the heavy industrial processes used to make PV panels. Even the polymers used to encase various elements could be grown, not fabricated, Silver suggests.

Silver says, "If you design it right, you could imagine having the ability to fabricate your technology on the lunar or Martian surface. Imagine looking at power systems not as something that is extremely valuable, but as something that can be grown as needed."

Fleshbots

Back on earth, MFCs have allowed scientists to take important steps towards making robots fully autonomous. To survive without human help, a robot needs to be able to generate its own energy. So Chris Melhuish and his team of robotics experts at the University of the West of England in Bristol developed a robot that catches flies and digests them in a special reactor cell that generates electricity.

Back on earth, MFCs have allowed scientists to take important steps towards making robots fully autonomous. To survive without human help, a robot needs to be able to generate its own energy. So Chris Melhuish and his team of robotics experts at the University of the West of England in Bristol developed a robot that catches flies and digests them in a special reactor cell that generates electricity.

Called EcoBot II, the robot is part of a drive to make "release and forget" robots that can be sent into dangerous or inhospitable areas to carry out remote industrial or military monitoring of, say, temperature or toxic gas concentrations. Sensors on the robot feed a data logger that periodically radios the results back to a base station.

The robot's energy source is the sugar in the polysaccharide called chitin that makes up a fly's exoskeleton. EcoBot II digests the flies in an array of eight microbial fuel cells, which use bacteria from sewage to break down the sugars, releasing electrons that drive an electric current (schematic, click to enlarge).

In its present form, EcoBot II still has to be manually fed fistfuls of dead bluebottles, but the ultimate aim of the UWE robotics team is to make the droid predatory, using sewage as a bait to catch the flies.

One of the great things about flies is that you can get them to come to you, says Melhuish. The team has yet to tackle this, but speculates that it is not a major problem; it would involve using a bottleneck-style flytrap with some form of pump to suck the flies into the digestion chambers.

With a top speed of 10 centimetres per hour, EcoBot II's roving prowess is still modest to say the least. Every 12 minutes it gets enough energy to take a step forwards two centimetres and send a transmission back, says Melhuish. But it does not need to catch too many flies to do so, says team member Ioannis Ieropoulos.

In tests, EcoBot II travelled for five days on just eight fat flies - one in each MFC.

So how do flies get turned into electricity? Each MFC comprises an anaerobic chamber filled with raw sewage slurry - donated by UWE's local utility, Wessex Water. The flies become food for the bacteria that thrive in the slurry.

Enzymes produced by the bacteria break down the chitin to release sugar molecules. These are then absorbed and metabolised by the bacteria. In the process, the bacteria release electrons that are harnessed to create an electric current.

Previous efforts to use carnivorous MFCs to drive a robot included an abortive UWE effort: the Slugbot. This was designed to hunt slugs on farms by using imaging systems to spot and grab the pests, and then deliver them to a digester that produces methane to power a fuel cell.

The electricity generated would have been used to charge the Slugbot when it arrived at a docking station. But the methane-based system took too long to produce power, and the team realised that MFCs offered far more promise.

Elsewhere, researchers in Florida created a train-like robot dubbed Chew Chew that used MFCs to charge a battery, but the bacteria had to be fed on sugar cubes.

For an autonomous robot to survive in the wild, relying on such refined foodstuffs is not an option, says Melhuish. EcoBot II, on the other hand, is the first robot to use unrefined fuel. Just do not stand downwind.

From these developments we can retain a few keywords that capture the interesting possibilities offered by microbial fuel cells: autonomy, self-replication, decentralisation, sustainability, renewability and the capacity to feed on an abundance and variety of primary feedstocks.

MFCs show that it's just a small step to connect the harsh environment of outer space to the remote rural areas of the developing world - both need reliable, efficient, decentralised and clean sources of energy.

References:

Yanzhen Fana, Hongqiang Hua and Hong Liu, "Enhanced Coulombic efficiency and power density of air-cathode microbial fuel cells with an improved cell configuration", Journal of Power Sources, Volume 171, Issue 2, 27 September 2007, Pages 348-354, doi:10.1016/j.jpowsour.2007.06.220

Oregon State University: New Microbial Fuel Cell Design Boosts Electricity Production - August 20, 2007.

MIT: Students shape materials for their own devices - September 27, 2007.

David Tenenbaum, "Power in Space: Time for a Biological Solution?", Astrobiology Magazine, May 14, 2007.

Intact Labs: Microbial Fuel Cells.

Chris Melhuish, John Greenman, Ian Horsfield, John Hart, Ioannis Ieropoulos, "Energy autonomy in robots through Microbial Fuel Cells" [*.pdf], IAS Lab, CEMS Faculty,, Applied Sciences Faculty, University of the West of England.

Microbial Fuel Cells, a website entirely devoted to the topic.

Geobacter and microbial fuel cell project (at the University of Massachusetts, Amherst).

Biopact: The bioeconomy at work: Sony develops most efficient biofuel cell ever, powered by sugar - August 23, 2007

Biopact: Sun Grant Initiative funds 17 bioenergy research projects - August 20, 2007

Recent design breakthroughs and efficiency leaps have taken microbial fuel cells out of their experimental status and ready to be used in concrete applications. The devices can clean waste water and deliver renewable energy while doing so. In principle they can be fed virtually any type of biomass, from rotten fruit and cellulose to algae and mosquitos. Electronic gadgets are already being powered by MFCs (earlier post). And thanks to self-sustaining microbial fuel cells, robots could soon perform difficult tasks fully autonomously by feeding on... flies. More importantly, scientists think biological fuel cells will revolutionize energy generation in space, but also in the developing world.

A bio-battery or microbial fuel cell converts chemical energy, available in an organic substrate, directly into electricity. To achieve this, bacteria are used as a catalyst to convert substrate into electrons. The micro-organisms can convert a huge variety of organic compounds into CO2, water and energy. They use the produced energy to grow and to maintain their own metabolism. However, by using a MFC we can harvest a part of this microbial energy in the form of electricity.

Schematic of a microbial fuel cell. Microbes in the anode compartment metabolize organic fuel (in this case glucose) and release electrons, ions and C02. In the cathode compartment electrons combine with ions and oxygen to form water and close the circuit. Credit: IntAct Labs

MFCs consist of an anode, a cathode, a proton or cation exchange membrane and an electrical ciruit. The bacteria live in the anode and convert a substrate such as glucose, acetate but also waste water into CO2, protons and electrons. Under aerobic conditions, bacteria use oxygen or nitrate as a final electron acceptor to produce water. However, in the anode of a MFC, no oxygen is present and bacteria need to switch from their natural electron acceptor to an insoluble acceptor, such as the MFC anode. Due to the ability of bacteria to transfer electrons to an insoluble electron acceptor, we can use a MFC to collect the electrons originating from the microbial metabolism. The electron transfer can occur either via membrane-associated components, soluble electron shuttles or nano-wires.The electrons then flow through an electrical circuit with a load or a resistor to the cathode. The potential difference (Volt) between the anode and the cathode, together with the flow of electrons (Ampere) results in the generation of electrical power (Watt). The protons flow through the proton or cation exchange membrane to the cathode. At the cathode, an electron acceptor is chemically reduced. Idealy, oxygen is reduced to water. To obtain a sufficient oxygen reduction reaction (ORR) rate a platina-catalyst is sometimes used. However, many researchers have meanwhile developed non-noble metal catalysts.

MFCs can be very large, several cubic meters by volume, or extremely small. Just like ordinary batteries, they can be coupled in series or in parallel. Until recently their energy density remained quite low. But major efficiency leaps are being made.

Efficiency breakthrough

In this week's issue of Journal of Power Sources, biological engineers at Oregon State University report they designed a microbial fuel cell that is capable of generating about 10 times more electricity than previously possible from an air cathode microbial fuel cell of the same size.

This design breakthrough could allow microbial fuel cells to be used more widely as sources of sustainable energy, says Hong Liu, lead author and assistant professor in the OSU Department of Biological and Ecological Engineering.

The new design could ultimately lead to portable systems for power generation that are simultaneously capable of providing reusable water for developing nations and remote areas. The fuel cell design could also significantly reduce the amount of electricity used at large wastewater treatment facilities.

The new design, developed with fellow OSU professor Yanzhen Fan and OSU graduate student Hongqiang Hu, involves sandwiching a cloth layer between the anode and the cathode parts of the microbial fuel cell, a configuration that greatly reduces the internal resistance, resulting in a much higher power density, Liu says.

In lab experiments, Liu’s team successfully generated 1,010 watts per cubic meter of reactor, or enough to power 16 60-watt light bulbs. The highest previous level of sustainable electricity generated from a cubic meter of air cathode microbial fuel cell is less than 115 watts. In experiments done even more recently, Liu and colleagues have generated more than 1,500 watts from the same reactor volume:

energy :: sustainability ::biomass :: bioenergy :: biofuels :: cellulose :: microbial fuel cell :: biofuel cell :: bio-battery :: decentralisation :: efficiency ::

energy :: sustainability ::biomass :: bioenergy :: biofuels :: cellulose :: microbial fuel cell :: biofuel cell :: bio-battery :: decentralisation :: efficiency :: The design improvements could eventually lead to a dramatic reduction in the cost of operating wastewater treatment plants in the U.S. and elsewhere. Five percent of the electricity in the U.S. is used for water and wastewater treatment, mainly to power pumps and other equipment. By incorporating microbial fuel cells in water treatment facilities, the cost of operation could be reduced, Liu says.

Although scaling up microbial fuel cells to help power large wastewater facilities is a long-term goal of Liu’s, she says small scale systems for households in the developing world will be feasible sooner.

It would be useful to build a smaller system for individual households. This is something the world can use very soon, especially in countries like China and India. Our research results are very promising. There is a real future here, and I hope we can make a small contribution to the world. - Hong Liu, assistant professor in the OSU Department of Biological and Ecological EngineeringWhile microbial fuel cells can't solve all global environmental and energy problems, they can be a great help. They can feed on virtually any type of biomass and generate clean, renewable power on the spot. Their capacity to clean waste water and deliver clean drinking water while simultaneously generating electricity, would allow developing countries to 'leapfrog' towards sustainable water treatment.

Liu’s research is supported in part by a $200,000 grant from the U.S. Department of Transportation through the Sun Grant Initiative, the OSU General Research Fund and the OSU Agricultural Research Foundation (earlier post on this interesting funding initiative that aims to kickstart the bioeconomy).

MIT BioVolt team: Ethan Crumlin G, Andrew Hoy, Joseph Walish DMSE G, Peter Weigele (consultant), John Craven, Gerardo Jose la O' DMSE G, and Jungik Kim (consultant) with two microbial fuel cell prototypes.

Like Liu, the winning MIT students see immediate applications for their MFC in the developing world, where millions of people are still not connected to the grid. Their BioVolt prototype unit, which relies anaerobic organisms to digest cellulose and convert it to electricity and water in a microbial fuel cell, could power households in remote villages in a decentralised manner.Across the world, biomass materials are currently utilized in vastly inefficient combustion processes (open fires) that lead to harmful smoke pollution and have become a primary factor in respiratory infections. Indoor smoke pollution kills an estimated 2 million women and children each year. Efficient and cost-effective MFCs could prompt households to use other types of biomass instead of wood, and switch to an electric future. This would solve a major health crisis and save forests.

Bio-power in space

The good thing about MFCs is that some of the world's top scientists in the space industry are working on them too, in futuristic settings. NASA researchers think they could power future space habitats (like a Mars base), because they are far more flexible than existing power systems. Their research could find applications in some of the poorest regions here on Earth.

The multiple advantages of biology's mechanisms become apparent when you take things to their extreme - to space. Traditional systems for making electricity in space depend on the hardest of hardware: photovoltaics (solar panels), hydrogen fuel cells, radioisotope thermal generators. These need to be 'manufactured' and hauled along. At a meeting of the NASA Institute for Advanced Concepts (NIAC) last fall, Matthew Silver, a space systems engineer who heads IntAct Labs in Cambridge, Mass., presented radical ideas for using biology and bioenergy instead, in a new generation of power supplies.

Unlike the older systems, the proposed devices would be 'grown' instead of 'manufactured'. They generate electrons using microbes that live in mud, or proteins native to the human ear or in photosynthetic bacteria. They would feed on carbohydrates contained in biomass that can readily be produced, stored and handled. In short, they would make the old science fiction concept of the 'carbohydrate economy' a reality.

In theory, biological power systems offer a number of advantages. Existing systems such as solar panels are based on physical and chemical processes that are difficult and costly to manufacture, and difficult to modify once fabricated. Biological systems may offer a high power-to-weight ratio, convenient fuel storage and many of them make useful byproducts like molecular oxygen. But the ultimate promise is this: they might be grown on demand, in space.

Conceptual drawing of a Mars base based on bio-power (click to enlarge). A greenhouse, microbial fuel cells, and algal growing compartments are all visible. Image by Chris Lund.

Credit: IntAct Labs

Some of the most promising bacteria emerging from recent MFC research concerns the genus Geobacter, an anaerobic organism that Derek Lovley, of the University of Massachusetts, discovered in sediment in 1987. To make energy, Geobacter oxidize organic matter, in the process transferring electrons to iron oxide particles in the surrounding soil or muck. In a fuel cell, a graphite electrode would substitute for the iron oxide as the electron acceptor. Because Geobacter and related organisms can create an electric current directly to electrodes, Lovley terms them 'electricigens'.Credit: IntAct Labs

Basing a fuel cell on microbes offers many theoretical advantages over the hydrogen or methane fuel cell, Lovley says. "A catalyst is not needed, and catalysts are normally expensive and easily fouled." A second advantage comes from the mucky nature of the fuel itself. "The fuel doesn't have to be clean," says Lovley. "It can actually be dirt, or waste products."

As Silver envisions it, a microbial fuel cell could digest human waste and other organic garbage during a trip to Mars. NASA's Waste Processing and Resource Recovery Workshop estimated that a crew of six would, on a low-carb diet, produce 10.55 kilograms of organic waste per day en route to Mars. That quantity of waste, Silver calculates, could produce up to about 1 kilowatt of constant power in a microbial fuel cell. NASA has estimated that life support systems on such a craft would need roughly 1 kilowatt per person during a cruise to Mars.

The carbon dioxide produced by bacterial oxidization of organic waste could be used to grow 'crops' in sunlit chambers, producing molecular oxygen as a byproduct. The feedstock could be algae or other carbohydrate containing plants, that could then be used to feed the microbial fuel cell and make more electricity. A similar process could create electricity on Mars.

While prototype microbial fuel cells have used a single strain of microbe, multiple organisms could increase the power output, particularly if the input were organic wastes. "We presented to NIAC the fact that different bacteria metabolize different things," says Silver. "A microbial fuel cell could use cascading chambers," where the output of one cell becomes the feedstock for a successive cell. For example, when bacteria in the genus Clostridium metabolize sugar, they do not use all the energy available in the sugar. Geobacter, however, can metabolize the waste products of some Clostridium, Silver suggests. Even better, Silver adds, through genetic engineering, "a novel organism could be designed that digests a greater range of inputs."

Using organic material as fuel leads to another advantage of microbial fuel cells for space exploration: organic matter is easy to store. While electricity from a photovoltaic panel must be stored in massive batteries or another complicated storage system, storage requirements for bacterial power units would be minimal, because the microbes could be fed to generate electricity as needed.

Another potential advantage of biological power systems is their "homegrown" potential. The complex material conversions needed to manufacture the power systems could be performed by microorganisms; they would not require the heavy industrial processes used to make PV panels. Even the polymers used to encase various elements could be grown, not fabricated, Silver suggests.

Silver says, "If you design it right, you could imagine having the ability to fabricate your technology on the lunar or Martian surface. Imagine looking at power systems not as something that is extremely valuable, but as something that can be grown as needed."

Fleshbots

Back on earth, MFCs have allowed scientists to take important steps towards making robots fully autonomous. To survive without human help, a robot needs to be able to generate its own energy. So Chris Melhuish and his team of robotics experts at the University of the West of England in Bristol developed a robot that catches flies and digests them in a special reactor cell that generates electricity.

Back on earth, MFCs have allowed scientists to take important steps towards making robots fully autonomous. To survive without human help, a robot needs to be able to generate its own energy. So Chris Melhuish and his team of robotics experts at the University of the West of England in Bristol developed a robot that catches flies and digests them in a special reactor cell that generates electricity.Called EcoBot II, the robot is part of a drive to make "release and forget" robots that can be sent into dangerous or inhospitable areas to carry out remote industrial or military monitoring of, say, temperature or toxic gas concentrations. Sensors on the robot feed a data logger that periodically radios the results back to a base station.

The robot's energy source is the sugar in the polysaccharide called chitin that makes up a fly's exoskeleton. EcoBot II digests the flies in an array of eight microbial fuel cells, which use bacteria from sewage to break down the sugars, releasing electrons that drive an electric current (schematic, click to enlarge).

In its present form, EcoBot II still has to be manually fed fistfuls of dead bluebottles, but the ultimate aim of the UWE robotics team is to make the droid predatory, using sewage as a bait to catch the flies.

One of the great things about flies is that you can get them to come to you, says Melhuish. The team has yet to tackle this, but speculates that it is not a major problem; it would involve using a bottleneck-style flytrap with some form of pump to suck the flies into the digestion chambers.

With a top speed of 10 centimetres per hour, EcoBot II's roving prowess is still modest to say the least. Every 12 minutes it gets enough energy to take a step forwards two centimetres and send a transmission back, says Melhuish. But it does not need to catch too many flies to do so, says team member Ioannis Ieropoulos.

In tests, EcoBot II travelled for five days on just eight fat flies - one in each MFC.

So how do flies get turned into electricity? Each MFC comprises an anaerobic chamber filled with raw sewage slurry - donated by UWE's local utility, Wessex Water. The flies become food for the bacteria that thrive in the slurry.

Enzymes produced by the bacteria break down the chitin to release sugar molecules. These are then absorbed and metabolised by the bacteria. In the process, the bacteria release electrons that are harnessed to create an electric current.

Previous efforts to use carnivorous MFCs to drive a robot included an abortive UWE effort: the Slugbot. This was designed to hunt slugs on farms by using imaging systems to spot and grab the pests, and then deliver them to a digester that produces methane to power a fuel cell.

The electricity generated would have been used to charge the Slugbot when it arrived at a docking station. But the methane-based system took too long to produce power, and the team realised that MFCs offered far more promise.

Elsewhere, researchers in Florida created a train-like robot dubbed Chew Chew that used MFCs to charge a battery, but the bacteria had to be fed on sugar cubes.

For an autonomous robot to survive in the wild, relying on such refined foodstuffs is not an option, says Melhuish. EcoBot II, on the other hand, is the first robot to use unrefined fuel. Just do not stand downwind.

From these developments we can retain a few keywords that capture the interesting possibilities offered by microbial fuel cells: autonomy, self-replication, decentralisation, sustainability, renewability and the capacity to feed on an abundance and variety of primary feedstocks.

MFCs show that it's just a small step to connect the harsh environment of outer space to the remote rural areas of the developing world - both need reliable, efficient, decentralised and clean sources of energy.

References:

Yanzhen Fana, Hongqiang Hua and Hong Liu, "Enhanced Coulombic efficiency and power density of air-cathode microbial fuel cells with an improved cell configuration", Journal of Power Sources, Volume 171, Issue 2, 27 September 2007, Pages 348-354, doi:10.1016/j.jpowsour.2007.06.220

Oregon State University: New Microbial Fuel Cell Design Boosts Electricity Production - August 20, 2007.

MIT: Students shape materials for their own devices - September 27, 2007.

David Tenenbaum, "Power in Space: Time for a Biological Solution?", Astrobiology Magazine, May 14, 2007.

Intact Labs: Microbial Fuel Cells.

Chris Melhuish, John Greenman, Ian Horsfield, John Hart, Ioannis Ieropoulos, "Energy autonomy in robots through Microbial Fuel Cells" [*.pdf], IAS Lab, CEMS Faculty,, Applied Sciences Faculty, University of the West of England.

Microbial Fuel Cells, a website entirely devoted to the topic.

Geobacter and microbial fuel cell project (at the University of Massachusetts, Amherst).

Biopact: The bioeconomy at work: Sony develops most efficient biofuel cell ever, powered by sugar - August 23, 2007

Biopact: Sun Grant Initiative funds 17 bioenergy research projects - August 20, 2007

--------------

--------------

PolyOne Corporation, the US supplier of specialised polymer materials, has opened a new colour concentrates manufacturing plant in Kutno, Poland. Located in central Poland, the new plant will produce colour products in the first instance, although the company says the facility can be expanded to handle other products. In March, the Ohio-based firm launched a range of of liquid colourants for use in bioplastics in biodegradable applications. The concentrates are European food contact compliant and can be used in polylactic acid (PLA) or starch-based blends.

PolyOne Corporation, the US supplier of specialised polymer materials, has opened a new colour concentrates manufacturing plant in Kutno, Poland. Located in central Poland, the new plant will produce colour products in the first instance, although the company says the facility can be expanded to handle other products. In March, the Ohio-based firm launched a range of of liquid colourants for use in bioplastics in biodegradable applications. The concentrates are European food contact compliant and can be used in polylactic acid (PLA) or starch-based blends.

1 Comments:

We'd be very interested to bring the financing the moment there is a working technology, enabling the inventors to share directly in the sale of electricity or of the end-product as close as possible to the end-user.

ARWbh GreenCell brings together the money of institutional investors and is able to finance anything and follow any-growth curve presented, the moment there is a provent technology on one side and customers that want to pay for the final-product or its products/utilities (electricity/gas/...) produced.

Post a Comment

Links to this post:

Create a Link

<< Home