European project looks at nanotechnology to develop CO2 capturing membranes

A new European project called 'Nanomembranes against Global Warming' (NanoGLOWA) is attempting to find a new way of capturing CO2 emissions from power plants with the help of nanotechnology. Nanostructured membranes could reduce carbon capture's energy consumption and costs, making it more attractive than current technology (earlier post). The €12 million NanoGLOWA project receives the bulk of its funding from the European Commission, and unites 26 organisations from 14 EU member states.

A new European project called 'Nanomembranes against Global Warming' (NanoGLOWA) is attempting to find a new way of capturing CO2 emissions from power plants with the help of nanotechnology. Nanostructured membranes could reduce carbon capture's energy consumption and costs, making it more attractive than current technology (earlier post). The €12 million NanoGLOWA project receives the bulk of its funding from the European Commission, and unites 26 organisations from 14 EU member states.Europe produces one gigaton of carbon dioxide annually and wafts it into the atmosphere. Around one-third of this stems from fossil-fuelled power plants. Carbon capture and storage (CCS) could reduce those emissions by up to 90%. The idea is to store the carbon thus captured underground in, for example, empty gas fields and aquifers.

Biopact follows developments in CCS technology because it allows for the creation of radically carbon-negative bioenergy and biofuels (more here, here and here, and references in these texts).

Existing carbon capture methods include absorption and non-selective cooling. During the absorption process, flue gasses - mainly consisting of nitrogen, water, dust particles and, of course, CO2 - flow through several baths in which the carbon dioxide is bound with amines. However, this 'scrubbing' technology is far from being energy- or cost-effective, as it can consume up to 25% of the energy actually produced, and large installations as well as chemicals are needed, says the NanoGLOWA team.

CO2 separation through membranes, on the other hand, would consume only up to 8% of the energy produced, and bring down installation costs. However, suitable membranes must first be developed (interesting flash presentation of current production methods).

The NanoGLOWA project is comprehensive in scope. It will develop, produce, and integrate nano-engineered membranes in power plants and test their carbon capturing effectiveness (project overview, schematic, click to enlarge).

Currently, the following five types of nanomembranes are simultaneously being designed in the framework of the project:

energy :: sustainability :: climate change :: carbon dioxide :: carbon capture and storage :: biofuels :: biomass :: bioenergy with carbon storage :: membranes :: nanotechnology ::

energy :: sustainability :: climate change :: carbon dioxide :: carbon capture and storage :: biofuels :: biomass :: bioenergy with carbon storage :: membranes :: nanotechnology :: - polymer membranes: diffusion transport membranes, block copolymers; fixed-site carrier-type membranes, cellulose acetate or polyamides; ionomeric high voltage membranes, electrically modified materials;

- carbon membranes: carbon molecular sieve membranes;

- ceramic membranes

Finally, ceramic membranes are very stable and have great longevity as they respond well to extreme conditions such as high temperatures. After development in academic laboratories, the membranes will be tested in pilot power plants in the fifth and final year of the project (2011).

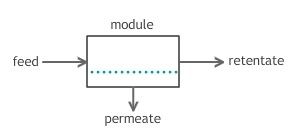

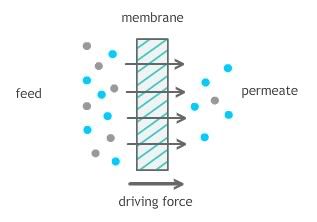

Membrane processes are characterized by the fact that a feed stream is divided into two streams, which are called the retentate stream and the permeate stream. Either of these streams can be the ‘product’ of the process. The membrane itself is the central part of every process and can be seen as a filter between two phases. The actual separation is achieved because transport of one component through the membrane is faster than the other component(s).

The NanoGLOWA project unites 26 organisations, including six universities and five power plant operators, as well as industry and small and medium-sized enterprises (SMEs) from 14 European countries. The project receives €7 million in funding from the European Commission under the Sixth Framework Programme. Total costs amount to €12.5 million.

References:

Cordis: Nanotechnology could help bring down costs of CO2 capture - September 25, 2007.

NanoGLOWA: How membranes are made - flash animation.

Biopact: New plastic-based, nano-engineered CO2 capturing membrane developed - September 19, 2007

--------------

--------------

According to Tarja Halonen, the Finnish president, one third of the value of all of Finland's exports consists of environmentally friendly technologies. Finland has invested in climate and energy technologies, particularly in combined heat and power production from biomass, bioenergy and wind power, the president said at the UN secretary-general's high-level event on climate change.

According to Tarja Halonen, the Finnish president, one third of the value of all of Finland's exports consists of environmentally friendly technologies. Finland has invested in climate and energy technologies, particularly in combined heat and power production from biomass, bioenergy and wind power, the president said at the UN secretary-general's high-level event on climate change.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home