Volvo releases comprehensive analysis of seven biofuels for use in carbon-neutral trucks

The Volvo Group today released results of an extensive analysis of seven different biofuels for use in demonstration trucks that run 100% on the renewable fuel without emitting any environmentally harmful carbon dioxide. The carbon-neutral trucks were equipped with diesel engines that have been modified to operate with the following renewable liquid and gaseous fuels: biodiesel, biogas combined with biodiesel, ethanol/methanol, DME, synthetic diesel and hydrogen gas combined with biogas.

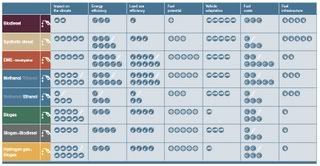

The full 'well-to-wheel' efficiency and sustainability of the alternative fuels was assessed using seven criteria and scored on a five point scale (table, click to enlarge) .

1. Impact on the climate: carbon dioxide emissions throughout the entire chain according to the well to wheel principle, which includes growing the raw material including fertilizer; harvesting the raw material; transporting it to the plant where the fuel is produced; production of the fuel; distribution to refuelling stations; the use of the fuel in vehicles. Calculations are based on fully renewable raw materials, but fossil fuels are currently used for cultivation or production. In future, it will be possible to replace fossil energy with renewable energy, however, with a lower level of efficiency as a result.

Results: five of the alternatives — synthetic diesel, dimethyl ether, methanol, biogas and hydrogen plus biogas — reduce the impact on the climate by more than 90%. In the case of methanol, gasification of black liquor is required in order to get the highest rating. For biogas and hydrogen gas combined with biogas, gasification of biomass is required in order to receive the highest rating. A lower rating applies if the biogas is produced through anaerobic digestion of household waste. Results for ethanol vary between 0 and 75 percent reduction depending on the production method. Biodiesel had the lowest ranking after ethanol.

2. Energy efficiency: was rated on a falling scale and is expressed in percent. The percentage indicates the amount of energy that reaches the vehicle’s driven wheels. By way of comparison, it can also be mentioned that with the fossil diesel fuel used today, we achieve approximately a 35 percent total level of efficiency. This relatively high level of efficiency is reached because raw oil can be considered to be a “semi-finished product” and the production of diesel is thereby very energy-efficient. The results may vary for the same fuel, depending on the production process used.

Results: DME and methanol receive the highest rating, on the condition that they are produced from black liquor from the wood pulp industry. The highest rating for synthetic diesel also requires the gasification of black liquor. The rating for biogas, biogas+biodiesel and hydrogen gas+biogas apply to production with gasification and anaerobic digestion. The production of biogas via gasification of black liquor is not included in the summary. The low rating for ethanol is due to the high energy consumption for cultivation and fuel production.

3. Land use efficiency: the yield per hectare for each crop has been calculated using information about average yields from good quality land. The rating scale indicates how far a heavy truck can travel per year and hectare. Growing conditions apply to Swedish conditions. Cultivation in other places leads to different results but the relationships are more or less the same. The researchers reduced the amount of fuel produced by the amount of fuel/energy required for harvesting, production, transport, etc. The results may vary for the same fuel, depending on the production process used.

Results: DME and methanol, combined with black liquor gasification get the highest rating. These fuels have high harvest yields, require little use of fossil fuels, and have high energy efficiency. Synthetic diesel has high harvest yields, requires little use of fossil fuels, but has lower energy efficiency and limited selectivity in production. Ethanol gets a low rating due to limited energy efficiency and in certain cases the need for a great deal of fossil energy. Biodiesel gets the lowest rating due to low average harvest yields and the use of a great deal of fossil energy. Biogas production via gasification of black liquor is not included in the summary. Biogas from anaerobic digestion scored high.

4. Fuel potential: the availability of raw material and the choice ofproduction process determine the amount of fuel that can be produced. Certain processes can use many different feedstocks and complete crops. Others are limited to parts of the contents of individual crops. A general problem with feedstocks from agricultural products is that they compete with food production. According to a study conducted by EUCAR/CONCAWE/JRC, the potential availability of waste wood, farmed wood, and straw in the EU in 2012 is approximately 700 TWh (Terawatt hours) per year while the potential for sunflower oil and rapeseed oil is estimated at approximately 80 TWh per year. The amount of fossil fuel that can be replaced by biomass varies depending on the level of efficiency in the fuel’s production process and in its final use. Biomass potential in the EU in 2012 is not adequate to replace fossil fuels. The import of biomass from better areas from a cultivation perspective may solve this problem:

energy :: sustainability ::carbon dioxide :: climate change :: biofuels :: ethanol :: biodiesel :: DME :: methanol :: Fischer-Tropsch :: biogas :: hydrogen ::

energy :: sustainability ::carbon dioxide :: climate change :: biofuels :: ethanol :: biodiesel :: DME :: methanol :: Fischer-Tropsch :: biogas :: hydrogen ::

Results: 350 to 420 TWh are equivalent to approximately 10-12% of the expected demand for petrol and diesel in the EU in 2015. DME, methanol, biogas, biogas+biodiesel and hydrogen gas+biogas get the highest rating. Synthetic diesel, DME, methanol, and biogas can all be produced from entire crops, wood feedstocks, or other biological material. However, synthetic diesel has a lower level of efficiency and provides a lower proportion of fuel that can be used in vehicles. With respect to biogas, waste material and sewage can be used in production. Ethanol can be produced from a number of feedstocks, including waste wood or other biological materials that contain cellulose, although the level of efficiency is relatively low. Biodiesel, which has received the lowest rating, is produced from vegetable oils such as rapeseed oil and sunflower oil. Availability is limited since rapeseed can only be grown on the same land every fourth year or every sixth year. Furthermore, only the oil in the seeds can be utilised for fuel.

5. Vehicle adaptation: a collective assessment was provided, explaining how technically complicated it is to adapt vehicles to the new fuels. This criterion also includes the fuel’s effect on the vehicle’s efficiency in different ways, such as maximal engine performance, weight increase, and range between refuelling. The last parameter mentioned can, for example, affect the vehicle’s load capacity. The technical complexity includes factors that require increased space for the fuel and the need for new and more expensive components. It also encompasses the need for technology to meet future emissions requirements. For example, certain fuels require more advanced emission controls than others.

Results : biodiesel and synthetic diesel get the highest rating. Vehicles that are run on these fuels are essentially comparable to conventional diesel vehicles. However, biodiesel requires increased service and has higher nitric oxide emissions. The lower energy content in DME results in a 50-percent reduction in range but it is still possible to use the fuel for long-haul transport. DME requires a unique and advanced fuel system, but also offers savings in terms of costs and weight with regard to exhaust noise damping and treatment of exhaust gases. Ethanol’s lower energy content results in a 30-percent shorter range per tank of fuel. Biogas+biodiesel offers maximal engine performance, but range is reduced by half if the gas is in liquid form. This also requires two separate fuel systems. Biogas and hydrogen gas+biogas require an Otto engine, which limits power output. The compressed gas has a low energy density, which limits range to approximately 20 percent. A complex tank system results in higher costs and increased weight.

6. Fuel costs: the assessment includes the costs of raw materials, fixed and variable costs in the production plants, and costs for transport, infrastructure, and energy consumption in the chain of distribution. Generally speaking, it is difficult to calculate future costs due to fluctuations in the price of raw materials and rapid technological development. Production costs for the fuel often comprise only a small part of the price to the end-user due to taxes, etc. The researchers compared costs here with conventional diesel fuel, exclusive of taxes, at a raw oil price of USD 70 a barrel. The comparison was made per litre of diesel equivalent. In other words, more than a litre of certain fuels is needed to get the same energy content as a litre of diesel. The results may vary for the same fuel, depending on the feedstock used.

Results: DME and methanol get the highest rating. When produced from black liquor, they are already competitive today in terms of costs. Production via gasification of forest products or farmed wood is more expensive. The cost of biodiesel is some 60 percent higher than for conventional diesel. With respect to biogas and hydrogen gas+biogas, the biogas based on waste materials leads to the most favourable results, primarily due to low feedstock costs. For biogas+biodiesel, biogas in liquid form is approximately 25 percent more expensive than compressed biogas. Biogas production through gasification of black liquor is not included in the summary. Synthetic diesel is the most expensive fuel because of high investment costs and the relatively low energy efficiency in production. Ethanol is generally expensive to produce. Production from forest products is the most expensive process.

7. Fuel infrastructure: the infrastructure is often considered to be the greatest challenge for an alternative fuel. It is an important criterion in terms of how quickly and easily a new fuel can be introduced and integrated into the existing infrastructure. However, it should be kept in mind that the infrastructure for conventional fuels also requires major investments. In the long term, the infrastructure is a secondary issue. This criterion also takes into account the safety and environmental aspects of handling the fuel in the infrastructure.

Ratings: synthetic diesel gets the highest rating. Synthetic diesel can easily be mixed with traditional diesel without jeopardising established standards and specifications. Biodiesel requires certain measures due to its lower storage stability. Methanol and ethanol require corrosion-resistant material, increased fire protection measures, and a separate infrastructure if they are used as pure fuel. Methanol should be handled in completely closed systems due to a high health risk. DME is a gas at room temperature and atmospheric pressure. In a vehicle, it is a liquid fuel at a pressure of 5 bar. The infrastructure for DME is similar to the one that has been established for Liquefied Petroleum Gas (LPG). DME is heavier than air and can accumulate in the event of leakage, resulting in a fire hazard. Biogas is handled at high pressure (200 bar) and requires the same infrastructure as the current system for natural gas. The infrastructure for hydrogen gas is the most expensive and complicated one since hydrogen gas requires even higher pressure than biogas.

The seven Volvo FM trucks were equipped with Volvo’s own 9-liter engines that have been specially modified by the group’s engineers to illustrate the possibilities of carbon-dioxide-free transport:

According to the widely publicized Stern report, approximately 14 percent of total global carbon-dioxide emissions will come from the transport sector, with road transport accounting for a total of 10 percent. However, there is no information on the percentage of these emission levels that in turn originate from cargo transport. A calculation based on European conditions and statistics, whereby passenger cars represent 60% of carbon-dioxide emissions and cargo transport for the remaining 40%, indicates that cargo transport will account for about 4-5% of total global carbon-dioxide emissions.

As one of the world’s largest manufacturers of heavy trucks, diesel engines and buses, the Volvo Group is part of the climate problem, says Leif Johansson, CEO of Volvo. But environmental issues are one of the areas which we have assigned the very highest priority, and based on our resources and knowledge, we both can and will be part of the solution.The seven trucks exhibited in Stockholm can be operated on the same number of different renewable fuels and/or combinations of fuels. Since all of these fuels are produced from renewable raw materials, they provide no carbon-dioxide contributions to the ecosystem when combusted and, accordingly, do not impact the environment.

Despite the current shortage of both biomass for the production of renewable fuels, and finished fuels, the Volvo Group does not view carbon-dioxide-free transport as a utopian idea. One of the reasons for this is the second generation of renewable fuels that are produced through gasification and that generate both large volumes and a greater number of fuels to choose between.

“Gasification is a promising line that may lead to a significantly larger substitution than today’s technology,” says Leif Johansson. “Our own history has taught us that much of what we once thought impossible we have since been able to solve a few years later. This can be applied to such important areas as energy efficiency and exhaust emission control. I am an optimist and believe in a similar trend in carbon-dioxide-free transport.”

References:

Volvo renewable fuels.

Collective overview of the ratings for seven biofuels.

The full 'well-to-wheel' efficiency and sustainability of the alternative fuels was assessed using seven criteria and scored on a five point scale (table, click to enlarge) .

1. Impact on the climate: carbon dioxide emissions throughout the entire chain according to the well to wheel principle, which includes growing the raw material including fertilizer; harvesting the raw material; transporting it to the plant where the fuel is produced; production of the fuel; distribution to refuelling stations; the use of the fuel in vehicles. Calculations are based on fully renewable raw materials, but fossil fuels are currently used for cultivation or production. In future, it will be possible to replace fossil energy with renewable energy, however, with a lower level of efficiency as a result.

Results: five of the alternatives — synthetic diesel, dimethyl ether, methanol, biogas and hydrogen plus biogas — reduce the impact on the climate by more than 90%. In the case of methanol, gasification of black liquor is required in order to get the highest rating. For biogas and hydrogen gas combined with biogas, gasification of biomass is required in order to receive the highest rating. A lower rating applies if the biogas is produced through anaerobic digestion of household waste. Results for ethanol vary between 0 and 75 percent reduction depending on the production method. Biodiesel had the lowest ranking after ethanol.

2. Energy efficiency: was rated on a falling scale and is expressed in percent. The percentage indicates the amount of energy that reaches the vehicle’s driven wheels. By way of comparison, it can also be mentioned that with the fossil diesel fuel used today, we achieve approximately a 35 percent total level of efficiency. This relatively high level of efficiency is reached because raw oil can be considered to be a “semi-finished product” and the production of diesel is thereby very energy-efficient. The results may vary for the same fuel, depending on the production process used.

Results: DME and methanol receive the highest rating, on the condition that they are produced from black liquor from the wood pulp industry. The highest rating for synthetic diesel also requires the gasification of black liquor. The rating for biogas, biogas+biodiesel and hydrogen gas+biogas apply to production with gasification and anaerobic digestion. The production of biogas via gasification of black liquor is not included in the summary. The low rating for ethanol is due to the high energy consumption for cultivation and fuel production.

3. Land use efficiency: the yield per hectare for each crop has been calculated using information about average yields from good quality land. The rating scale indicates how far a heavy truck can travel per year and hectare. Growing conditions apply to Swedish conditions. Cultivation in other places leads to different results but the relationships are more or less the same. The researchers reduced the amount of fuel produced by the amount of fuel/energy required for harvesting, production, transport, etc. The results may vary for the same fuel, depending on the production process used.

Results: DME and methanol, combined with black liquor gasification get the highest rating. These fuels have high harvest yields, require little use of fossil fuels, and have high energy efficiency. Synthetic diesel has high harvest yields, requires little use of fossil fuels, but has lower energy efficiency and limited selectivity in production. Ethanol gets a low rating due to limited energy efficiency and in certain cases the need for a great deal of fossil energy. Biodiesel gets the lowest rating due to low average harvest yields and the use of a great deal of fossil energy. Biogas production via gasification of black liquor is not included in the summary. Biogas from anaerobic digestion scored high.

4. Fuel potential: the availability of raw material and the choice ofproduction process determine the amount of fuel that can be produced. Certain processes can use many different feedstocks and complete crops. Others are limited to parts of the contents of individual crops. A general problem with feedstocks from agricultural products is that they compete with food production. According to a study conducted by EUCAR/CONCAWE/JRC, the potential availability of waste wood, farmed wood, and straw in the EU in 2012 is approximately 700 TWh (Terawatt hours) per year while the potential for sunflower oil and rapeseed oil is estimated at approximately 80 TWh per year. The amount of fossil fuel that can be replaced by biomass varies depending on the level of efficiency in the fuel’s production process and in its final use. Biomass potential in the EU in 2012 is not adequate to replace fossil fuels. The import of biomass from better areas from a cultivation perspective may solve this problem:

energy :: sustainability ::carbon dioxide :: climate change :: biofuels :: ethanol :: biodiesel :: DME :: methanol :: Fischer-Tropsch :: biogas :: hydrogen ::

energy :: sustainability ::carbon dioxide :: climate change :: biofuels :: ethanol :: biodiesel :: DME :: methanol :: Fischer-Tropsch :: biogas :: hydrogen :: Results: 350 to 420 TWh are equivalent to approximately 10-12% of the expected demand for petrol and diesel in the EU in 2015. DME, methanol, biogas, biogas+biodiesel and hydrogen gas+biogas get the highest rating. Synthetic diesel, DME, methanol, and biogas can all be produced from entire crops, wood feedstocks, or other biological material. However, synthetic diesel has a lower level of efficiency and provides a lower proportion of fuel that can be used in vehicles. With respect to biogas, waste material and sewage can be used in production. Ethanol can be produced from a number of feedstocks, including waste wood or other biological materials that contain cellulose, although the level of efficiency is relatively low. Biodiesel, which has received the lowest rating, is produced from vegetable oils such as rapeseed oil and sunflower oil. Availability is limited since rapeseed can only be grown on the same land every fourth year or every sixth year. Furthermore, only the oil in the seeds can be utilised for fuel.

5. Vehicle adaptation: a collective assessment was provided, explaining how technically complicated it is to adapt vehicles to the new fuels. This criterion also includes the fuel’s effect on the vehicle’s efficiency in different ways, such as maximal engine performance, weight increase, and range between refuelling. The last parameter mentioned can, for example, affect the vehicle’s load capacity. The technical complexity includes factors that require increased space for the fuel and the need for new and more expensive components. It also encompasses the need for technology to meet future emissions requirements. For example, certain fuels require more advanced emission controls than others.

Results : biodiesel and synthetic diesel get the highest rating. Vehicles that are run on these fuels are essentially comparable to conventional diesel vehicles. However, biodiesel requires increased service and has higher nitric oxide emissions. The lower energy content in DME results in a 50-percent reduction in range but it is still possible to use the fuel for long-haul transport. DME requires a unique and advanced fuel system, but also offers savings in terms of costs and weight with regard to exhaust noise damping and treatment of exhaust gases. Ethanol’s lower energy content results in a 30-percent shorter range per tank of fuel. Biogas+biodiesel offers maximal engine performance, but range is reduced by half if the gas is in liquid form. This also requires two separate fuel systems. Biogas and hydrogen gas+biogas require an Otto engine, which limits power output. The compressed gas has a low energy density, which limits range to approximately 20 percent. A complex tank system results in higher costs and increased weight.

6. Fuel costs: the assessment includes the costs of raw materials, fixed and variable costs in the production plants, and costs for transport, infrastructure, and energy consumption in the chain of distribution. Generally speaking, it is difficult to calculate future costs due to fluctuations in the price of raw materials and rapid technological development. Production costs for the fuel often comprise only a small part of the price to the end-user due to taxes, etc. The researchers compared costs here with conventional diesel fuel, exclusive of taxes, at a raw oil price of USD 70 a barrel. The comparison was made per litre of diesel equivalent. In other words, more than a litre of certain fuels is needed to get the same energy content as a litre of diesel. The results may vary for the same fuel, depending on the feedstock used.

Results: DME and methanol get the highest rating. When produced from black liquor, they are already competitive today in terms of costs. Production via gasification of forest products or farmed wood is more expensive. The cost of biodiesel is some 60 percent higher than for conventional diesel. With respect to biogas and hydrogen gas+biogas, the biogas based on waste materials leads to the most favourable results, primarily due to low feedstock costs. For biogas+biodiesel, biogas in liquid form is approximately 25 percent more expensive than compressed biogas. Biogas production through gasification of black liquor is not included in the summary. Synthetic diesel is the most expensive fuel because of high investment costs and the relatively low energy efficiency in production. Ethanol is generally expensive to produce. Production from forest products is the most expensive process.

7. Fuel infrastructure: the infrastructure is often considered to be the greatest challenge for an alternative fuel. It is an important criterion in terms of how quickly and easily a new fuel can be introduced and integrated into the existing infrastructure. However, it should be kept in mind that the infrastructure for conventional fuels also requires major investments. In the long term, the infrastructure is a secondary issue. This criterion also takes into account the safety and environmental aspects of handling the fuel in the infrastructure.

Ratings: synthetic diesel gets the highest rating. Synthetic diesel can easily be mixed with traditional diesel without jeopardising established standards and specifications. Biodiesel requires certain measures due to its lower storage stability. Methanol and ethanol require corrosion-resistant material, increased fire protection measures, and a separate infrastructure if they are used as pure fuel. Methanol should be handled in completely closed systems due to a high health risk. DME is a gas at room temperature and atmospheric pressure. In a vehicle, it is a liquid fuel at a pressure of 5 bar. The infrastructure for DME is similar to the one that has been established for Liquefied Petroleum Gas (LPG). DME is heavier than air and can accumulate in the event of leakage, resulting in a fire hazard. Biogas is handled at high pressure (200 bar) and requires the same infrastructure as the current system for natural gas. The infrastructure for hydrogen gas is the most expensive and complicated one since hydrogen gas requires even higher pressure than biogas.

The seven Volvo FM trucks were equipped with Volvo’s own 9-liter engines that have been specially modified by the group’s engineers to illustrate the possibilities of carbon-dioxide-free transport:

The diesel engine is an extremely efficient energy converter that is perfectly suited to many different renewable fuels, liquid or gaseous. With our know-how in engine technology and our large volumes, we can manufacture engines for several different renewable fuels, and also create possibilities for carbon-dioxide-free transports in such other product areas as buses, construction equipment and boats. - Jan-Eric Sundgren, member of Volvo Group Management and Senior Vice President, Public and Environmental AffairsClimate change, transport and responsibility

According to the widely publicized Stern report, approximately 14 percent of total global carbon-dioxide emissions will come from the transport sector, with road transport accounting for a total of 10 percent. However, there is no information on the percentage of these emission levels that in turn originate from cargo transport. A calculation based on European conditions and statistics, whereby passenger cars represent 60% of carbon-dioxide emissions and cargo transport for the remaining 40%, indicates that cargo transport will account for about 4-5% of total global carbon-dioxide emissions.

As one of the world’s largest manufacturers of heavy trucks, diesel engines and buses, the Volvo Group is part of the climate problem, says Leif Johansson, CEO of Volvo. But environmental issues are one of the areas which we have assigned the very highest priority, and based on our resources and knowledge, we both can and will be part of the solution.The seven trucks exhibited in Stockholm can be operated on the same number of different renewable fuels and/or combinations of fuels. Since all of these fuels are produced from renewable raw materials, they provide no carbon-dioxide contributions to the ecosystem when combusted and, accordingly, do not impact the environment.

With these vehicles, we have shown that Volvo is ready, that we possess the technology and the resources for carbon-dioxide-free transport, but we cannot do this alone. We also require large-scale production of renewable fuels and putting such production in operation requires extensive investments in research and development, and also well-defined, common guidelines from authorities in as many countries as possible. - Leif Johansson, CEO of the Volvo GroupPromising results from gasification

Despite the current shortage of both biomass for the production of renewable fuels, and finished fuels, the Volvo Group does not view carbon-dioxide-free transport as a utopian idea. One of the reasons for this is the second generation of renewable fuels that are produced through gasification and that generate both large volumes and a greater number of fuels to choose between.

“Gasification is a promising line that may lead to a significantly larger substitution than today’s technology,” says Leif Johansson. “Our own history has taught us that much of what we once thought impossible we have since been able to solve a few years later. This can be applied to such important areas as energy efficiency and exhaust emission control. I am an optimist and believe in a similar trend in carbon-dioxide-free transport.”

References:

Volvo renewable fuels.

Collective overview of the ratings for seven biofuels.

--------------

--------------

The government of the Indian state of Orissa announced its policy for biofuel production which includes a slew of incentives as well as measures to promote the establishment of energy plantations. The state aims to bring 600,000 hectares of barren and fallow land under Jatropha and Karanj. At least 2 million hectares degraded land are available in the State. The new policy's other objectives are to provide a platform for investors and entrepreneurs, market linkages and quality control measures.

The government of the Indian state of Orissa announced its policy for biofuel production which includes a slew of incentives as well as measures to promote the establishment of energy plantations. The state aims to bring 600,000 hectares of barren and fallow land under Jatropha and Karanj. At least 2 million hectares degraded land are available in the State. The new policy's other objectives are to provide a platform for investors and entrepreneurs, market linkages and quality control measures.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home