Berkeley Lab tests ultraclean combustion technology with hydrogen

Biohydrogen, biomethane and biomass based syngas may soon be burned in an experimental gas turbine simulator equipped with an ultralow-emissions combustion technology to yield extremely clean renewable electricity. Called LSI, the technique has been tested successfully using pure hydrogen as a fuel – a milestone that indicates a potential to help eliminate millions of tons of carbon dioxide and thousands of tons of NOx from power plants each year.

Biohydrogen, biomethane and biomass based syngas may soon be burned in an experimental gas turbine simulator equipped with an ultralow-emissions combustion technology to yield extremely clean renewable electricity. Called LSI, the technique has been tested successfully using pure hydrogen as a fuel – a milestone that indicates a potential to help eliminate millions of tons of carbon dioxide and thousands of tons of NOx from power plants each year.The LSI - low-swirl injector - technology (more here and here) was developed by Robert Cheng of the U.S. Department of Energy’s Lawrence Berkeley National Laboratory and is seen as one of the most promising combustion technologies around.

The LSI holds great promise for its near-zero emissions of nitrogen oxides gases that are emitted during the combustion of fuels such as natural gas during the production of electricity. Nitrogen oxides, or NOx, are greenhouse gases as well as components of smog.

The Department of Energy’s Office of Electricity Delivery and Energy Reliability initially funded the development of the LSI for use in industrial gas turbines for on-site (i.e. distributed) electricity production. The purpose of this research was to develop a natural gas-burning turbine using the LSI’s ability to substantially reduce NOx emissions.

Cheng, Berkeley Lab colleague David Littlejohn, and Kenneth Smith and Wazeem Nazeer from Solar Turbines Inc. of San Diego adapted the low-swirl injector technology to the Taurus 70 gas turbine that produces about seven megawatts of electricity. The team’s effort garnered them won them a 2007 R&D 100 award from R&D magazine.

Right: A prototype of the low-swirl injector. Fuel flows through the openings of the center channel. This simple design creates the low-swirl flow, with lower emissions of NOx the result. Left: A cutaway view of Solar Turbines' Taurus 70 engine. The research team has adapted the low swirl injector for use in this technology, which is similar to a jet engine, but is used to generate electricity in power plants on the ground (click to enlarge).

The team is continuing the LSI development for use with carbon-neutral renewable fuels such as biomethane, biogas, biohydrogen or (bio-based) syngas, and other industrial processes such as petroleum refining and waste treatments.DOE’s Office of Fossil Energy is funding another project in which the LSI is being tested for its ability to burn syngas (a mixture of hydrogen and carbon monoxide) and hydrogen fuels in an advanced IGCC plant (Integrated Gasification Combined Cycle) called FutureGen, which is planned to be the world’s first near-zero-emissions coal power plant. The intention of the FutureGen plant is to produce hydrogen from gasification of coal and sequester the carbon dioxide generated by the process. The LSI is one of several combustion technologies being evaluated for use in the 200+- megawatt utility-size hydrogen turbine that is a key component of the FutureGen plant.

The collaboration between Berkeley Lab and the National Energy Technology Laboratory (NETL) in Morgantown, WV, recently achieved the milestone of successfully test-firing an LSI unit using pure hydrogen as its fuel.

Ultra-clean gas combustion

Because the LSI is a simple and cost-effective technology that can burn a variety of fuels, it has the potential to help eliminate millions of tons of carbon dioxide and thousands of tons of NOx from power plants each year:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biogas :: biomethane :: biohydrogen :: syngas :: greenhouse gas emissions :: combustion :: gas turbine ::

energy :: sustainability :: biomass :: bioenergy :: biofuels :: biogas :: biomethane :: biohydrogen :: syngas :: greenhouse gas emissions :: combustion :: gas turbine :: In a letter of support to the R&D 100 selection committee, Leonard Angello, manager of Combustion Turbine Technology for the Electric Power Research Institute, wrote: “I am impressed by the potential of this device as a critical enabling technology for the next generation coal-based Integrated Gasification Combined Cycle power plants with CO2 capture…This application holds promise for the gas turbines in IGCC power plants that operate on high-hydrogen-content syngas fuels or pure hydrogen.”

How the technology works

The low swirl injector is a mechanically simple device with no moving parts that imparts a mild spin to the gaseous fuel and air mixture that causes the mixture to spread out. The flame is stabilized within the spreading flow just beyond the exit of the burner. Not only is the flame stable, but it also burns at a lower temperature than that of conventional burners. The production of nitrogen oxides is highly temperature-dependent, and the lower temperature of the flame reduces emissions of nitrogen oxides to very low levels.

“The LSI principle defies conventional approaches,” says Cheng. “Combustion experts worldwide are just beginning to embrace this counter-intuitive idea. Principles from turbulent fluid mechanics, thermodynamics, and flame chemistry are all required to explain the science underlying this combustion phenomenon.”

Natural gas-burning turbines with the low-swirl injector emit an order of magnitude lower levels of NOx than conventional turbines. Tests at Berkeley Lab and Solar Turbines showed that the burners with the LSI emit 2 parts per million of NOx (corrected to 15% oxygen), more than five times times less than conventional burners.

A more significant benefit of the LSI technology is its ability to burn a variety of different fuels from natural gas to hydrogen - all fuels that can be made from renewable biomass - and the relative ease to incorporate it into current gas turbine design. Extensive redesign of the turbine is not needed. The LSI is being designed as a drop-in component for gas-burning turbine power plants.

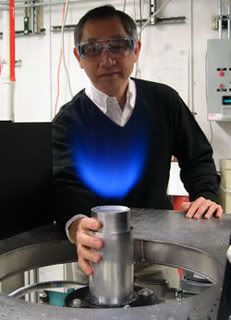

Top image: Robert Cheng views an LSI flame. He is touching the burner, demonstrating that it stays cool because the flame is completely lifted from its body.

References:

Berkely Lab: Berkeley Lab’s Ultraclean Combustion Technology For Electricity Generation Fires Up in Hydrogen Tests - August 1, 2007.

Berkely Lab Technology Transfer: Ultraclean Low Swirl Combustion.

Berkely Lab: Low-swirl combustion information page.

The U.S. DOE’s FutureGen initiative.

--------------

--------------

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

Taiwan's Feng Chia University has succeeded in boosting the production of hydrogen from biomass to 15 liters per hour, one of the world's highest biohydrogen production rates, a researcher at the university said Friday. The research team managed to produce hydrogen and carbon dioxide (which can be captured and stored) from the fermentation of different strains of anaerobes in a sugar cane-based liquefied mixture. The highest yield was obtained by the Clostridium bacterium.

1 Comments:

A more significant benefit of the LSI technology is its ability to burn a variety of different fuels from natural gas to hydrogen - all fuels that can be made from renewable biomass - and the relative ease to incorporate it into current gas turbine design. Extensive redesign of the turbine is not needed. The LSI is being designed as a drop-in component for gas-burning turbine power plants.

Post a Comment

Links to this post:

Create a Link

<< Home