An in-depth look at biorefinery concepts

The executive committee of IEA Bioenergy recently held its 59th meeting where it discussed the concept of the integrated biorefinery. Twelve leading experts presented case-studies and analyses on the barriers and opportunities ahead for such efficient factories that will drive the nascent bioeconomy. IEA Bioenergy is an international collaboration in which national experts from research, government, and industry from the IEA's Member Countries pool R&D in the area of bioenergy and formulate strategies on how to foster the deployment of bioenergy worldwide.

The executive committee of IEA Bioenergy recently held its 59th meeting where it discussed the concept of the integrated biorefinery. Twelve leading experts presented case-studies and analyses on the barriers and opportunities ahead for such efficient factories that will drive the nascent bioeconomy. IEA Bioenergy is an international collaboration in which national experts from research, government, and industry from the IEA's Member Countries pool R&D in the area of bioenergy and formulate strategies on how to foster the deployment of bioenergy worldwide.Put in simple terms, the concept of the biorefinery is based on converting series of renewable biomass streams via biochemical and thermochemical conversion pathways into an optimal range of products: biofuels, power and heat, biomaterials and green platform and bulk chemicals. All this must be achieved in as efficient a manner as possible by integrating conversion processes. In this sense, biorefining is analogous to the operations at refineries in the petrochemical industry.

The first session at the excom meeting provided an overview of the strategies that various countries are using to accelerate the commercialisation of the biorefinery concept, with a main focus on biochemical conversion. In a second session, thermochemical conversion technologies, 'Integrated Biomass Utilisation Systems' (IBUS), and Integrated Cereal Production were discussed. In a next gathering, the experts looked at strategies aimed at making use of entire plants and byproducts, also called 'bio-cascading'. The final session was entirely devoted to Iogen's experience and to the U.S. Department of Energy's activities at its Golden Field Office. What follows are some highlights from these presentations, which allow for a deeper understanding of the challenges ahead for the establishment of biorefineries.

Paths to commercialisation

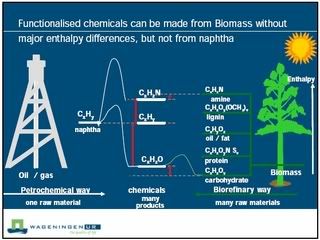

In his presentation titled Biorefinery, the Bridge Between Agriculture and Chemistry Ed de Jong of the Wageningen University and Research Centre (WUR) in the Netherlands sketched the relationship between agricultural feedstocks for a bio-based chemical industry.

The major bridge between agriculture and chemistry is different in every country. For example, in the USA, security of the supply of feedstocks for the agriculture and chemical industries is the most important issue. Without reliable feedstocks, the chemical industry cannot depend on biomass as a major feedstock in chemical processing. Other countries have made efforts to ensure that finished products are produced by biomass feedstocks. In Holland, a number of task forces have been established to increase development of bioenergy, specifically 30% from biomass by 2030. In addressing these issues, many countries realise the importance of supply chains and co-production of alternative products through biomass:

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioproducts :: green chemistry :: biorefinery :: bioeconomy :: IEA Bioenergy ::

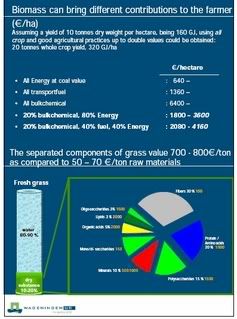

energy :: sustainability :: biomass :: bioenergy :: biofuels :: bioproducts :: green chemistry :: biorefinery :: bioeconomy :: IEA Bioenergy :: The contribution to farmers from the supply chain is also important because producing and selling biomass needs to be economically feasible for farmers. A combination of different products from both the farmer and the chemical industry will increase potential revenue and provide stronger incentives. The importance of co-products is exemplified in a pilot plant established in northern Holland ten years ago, which converted grass into products with multiple applications.

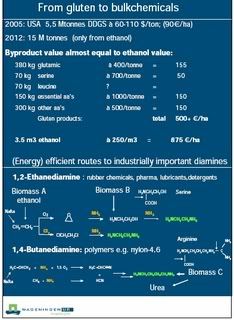

There is renewed interest from the chemical industry in the pulp and paper industry because of rising prices of traditional feedstocks, and pulp and paper waste streams are now a more economically feasible feedstock. Chemicals can be made from biomass without major inputs. When converting biomass-to-ethanol, the by-products produced are almost equal in value to the ethanol produced. Ethanol can be easily transformed into a chemical and can develop other materials, increasing the attractiveness of the chemical.

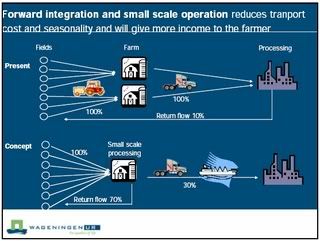

There are advantages of small-scale processing, such as harvesting in the fields with lower transport costs and reduced water. The disadvantages are that economies of scale in small-scale processing prevent profits for biological processes. A major need is to lower raw material costs and have better refinery separation technologies and downstream processes.

Interestingly, as an example of small-scale and decentralised biorefineries, de Jong pointed at mobile cassava starch processing plants that are under development. Such mobile factories may provide a starting point for the creation of future small biorefineries in the developing world.

The integrated biorefinery increases the value chain of individual biomass components as well as co-products produced. The biorefinery bridges the gap between agriculture and the chemical industries by providing a stream for biomass feedstocks and producing a menu of finished chemical products. When these products are produced from non fossil-fuelled feedstock, they also strategically achieve country goals of renewable energy production.

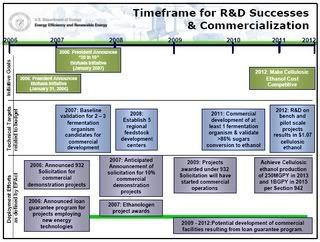

In Commercialising Biorefineries: The Path Forward, Larry Russo of the U.S. Department of Energy started out by providing an overview of America's R&D activities that will bring commercially viable biorefineries to the market.

This presentation covered the multi-faceted strategy and timeframe based on analysis, a presidential initiative, and the drive to reduce dependence on foreign oil.

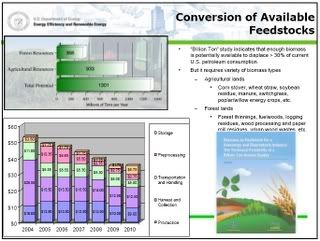

In April 2005, the US Department of Energy (DOE) published the study entitled 'Biomass as Feedstock for Bioenergy and Bio Products Industry: The Technical Feasibility of a Billion Ton Annual Supply'. This report indicated that USA has the potential to displace 30% of current USA petroleum consumption using a variety of biomass feedstocks such as corn stover, wheat straw, and switch grass. This analysis provided the foundation for DOE to pursue a strategy that examines multiple biomass feedstocks.

USA biomass R&D effort was further shaped by the announcement of the Presidential Biofuels Initiative. This initiative set the goal in 2004 to achieve biofuels production to displace 30% of the nation’s gasoline use by 2030. This presidential goal is in response to the need for a domestic fuel source to reduce USA dependence on foreign oil. To achieve this goal, USA structured its government-funded research portfolio along five pathways:

- Feedstock R&D

- Biochemical R&D

- Thermochemical R&D

- Products R&D

- Balance of Plant

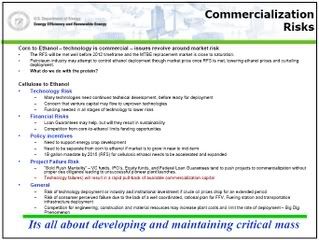

In the effort to commercialise the biorefinery concept, DOE considers its critical role to be the mitigation of risk associated with the commercialisation of emerging technologies. At present there is significant private investment in biofuels development, although early failures in R&D efforts could jeopardise further investment. Therefore, DOE plans to provide 80 to 100% of the funds needed for basic R&D and technology development.

As the technologies mature and the projects demonstrate proof-of-concept and commercial viability, the government share of the funding is reduced and more of the financial burden is shifted to the commercial sector. This is the case with US DOE 932 solicitation, which aims to provide loan guarantees for the development of commercial biorefineries. These loan guarantees mitigate the financial burden on lending institutions because the USA government is held responsible should the recipient default on the loan.

Although a major portion of USA policy aimed at reducing the nation’s dependence on foreign oil is centred on biofuels, USA recognises the need for a balanced approach to achieving its goal. USA has begun to examine the need for more flexible fuel vehicles and improvements in the fuelling infrastructure. DOE also is pursuing efforts to improve the efficiency of automobiles for petroleum combustion, as well as the miles-per-gallon that can be achieved with ethanol fuels. USA believes that the goal of reducing the nation’s dependence on foreign oil can be achieved most readily through these efforts to develop biorefineries while also improving vehicle fuel efficiencies and the fuelling infrastructure.

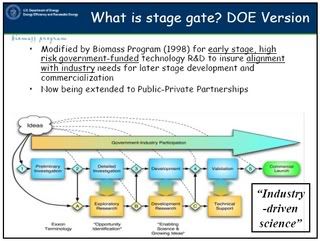

Bob Wooley, of the United States National Renewable Energy Laboratory (NREL) spoke about Insuring Success through Stage Gate and Beyond. The 'Stage Gate Process' that the DOE is using to track the progress of the projects within its R&D portfolio was the main focus of the presentation.

This Stage Gate process enables the evaluation of a project’s performance in bringing science and technology to commercial applications quicker, at lower costs, and with improved probability of success. This is accomplished by tracking the project from the beginning of the R&D stage. This process provides a framework for each project to go through a series of stage gate reviews before receiving support to progress to the next stage. Each stage begins with heavy government involvement and moves toward more industry involvement as a project progresses. In this process, commercialisation must be the end goal. The process is structured to incorporate steps such as exploratory research, development research, and technical support to address problems that will occur when moving to the commercialisation phase.

In the Stage Gate process, it is important to review previously completed work. During this review, it may be determined that a project should be stopped. The process may also determine whether there are incomplete parts and more work is needed, or whether a project could proceed to the next stage. The final assessment is critical to making sure that the best projects are being pursued.

The Stage Gate process is not a new concept. The Independent Project Analysis, Inc. (IPA), originated under the Rand Corporation in the 1970s, has used this process for a variety of research portfolios including evaluating the synfuels industry. IPA independently measures the performance of capital projects and the risk of possible unknown factors, determines what can be done to mitigate these issues, and predicts project success based on the research factors. It makes suggestions on how outcomes of commercial projects can be improved. DOE has enlisted the services of IPA to help implement the Stage Gate Process and manage the DOE biorefinery development projects, to ensure projects will be successful.

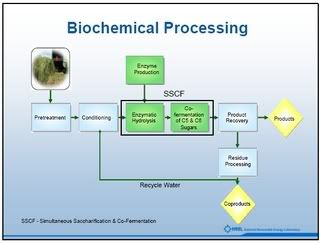

Finally, the first session saw Dan Schell, also of the NREL, discussing ways of Proving Biochemical Technologies at the Pilot-scale for Integrated Biorefinery Development.

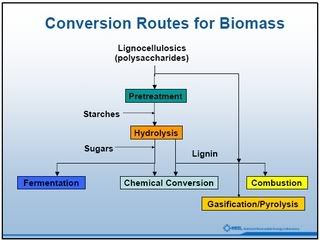

Schell first outlined the different biomass conversion paths, with the biochemical route only being one of those. Thermochemical pathways consist of biomass gasification and pyrolysis. Different plant components require separate processing routes.

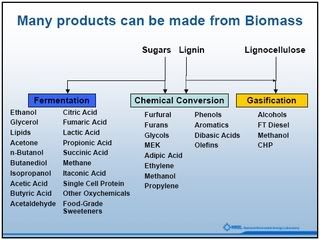

These different processes promise the production of a wide range of green and renewable bulk and platform chemicals, depending on which parts of plants are converted.

Schell then gave an overview of NREL’s pilot-scale biochemical biorefinery and how it is a critical tool in furthering the commercialisation of biorefinery technologies. This facility was constructed to generate critical information about the behaviour of the system for use in the design of larger commercial demonstration facilities.

NREL has found that pilot-scale plants are less expensive to build and operate when compared to commercial scale facilities. The rationale behind pilot plants is that they enables the laboratory to test the feasibility of proposed processes and implement process changes. It also enables the laboratory to research solutions to potential bottlenecks that can occur when implementing a new technology or process. This testing arrangement is much more cost effective than demonstrating these new technologies and processes at a commercial facility. Another benefit that the pilot-scale plant provides NREL is the ability to obtain data for design of a full-scale plant for variety of topical areas such as chemical reactions, mass and heat balances, material for construction, control strategies, and operating costs. The plant allows NREL to gather metrics associated with competing technologies in terms of cost and productivity, in order to provide the commercial sector with the data needed for more informed business decisions.

NREL is in the process of adding new capabilities to its pilot plant to enable it to handle a wider range of preterament chemistries. The laboratory is also adding new unit operations and expanding the instrument and control capabilities. These expansions will enable the lab to provide more useful information to the commercial sector and facilitate the deployment of more technologies into the marketplace.

Thermochemical conversion, process integration

Session two was entirely devoted to different thermochemical biomass conversion technologies and process integration.

One of the challenges facing biorefineries is to develop thermochemical technologies that are technically and economically feasible at the appropriate scale for reasonably available biomass resources. The goal of most biorefineries is to produce cost competitive biofuels at approximately US$1/gallon and to mix them with gasoline to meet industry, federal, and state specifications. To achieve this goal, biorefineries need to integrate bioethanol and electricity combined with heat to create processing efficiencies. Biorefinery production facilities have different phases: the demonstration plant, phase one (generation), and commercial plants. Second generation biorefineries are being set up in York, UK and Salamanca, Spain.

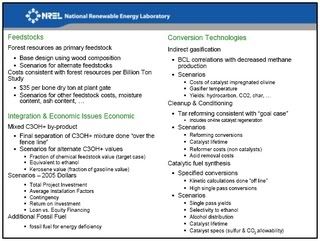

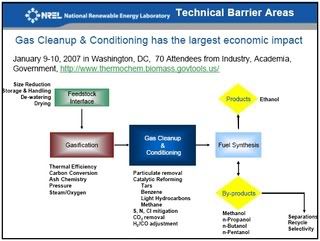

David Dayton, NREL, presented: Pilot-scale Thermochemical Technologies for Integrated Biorefinery Development - The Thermochemical Conversion Platform. In this presentation, Dayton explained that biorefineries utilise two main processes, biochemical and thermochemical, in converting raw biomass feedstocks such as wood chips into finished products such as ethanol.

A wide variety of lignocellulosic feedstocks is available even though the bulk will be obtained from forestry operations and wood waste. In line with the 'Billion Ton Study', several economic and technological scenarios for the thermochemical conversion of this woody biomass have been identified.

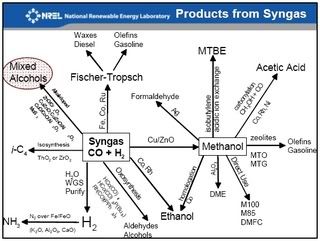

Thermochemical conversion utilises heat and pressure to convert carbon into finished products. Two main and different thermochemical conversion paths are gasification and pyrolysis. Dayton primarily discussed the gasification route, which results in a hydrogen an carbon monoxide 'syngas' which forms the basis for the transformation into different products.

There are several barriers for thermochemical conversion in biorefineries: analysis, conversion, gas clean-up and conditioning - identified as the barrier with the largest economic impact - , and integration of operations.

Multiple feedstocks necessitate multiple conversion processes, which complicate the process. Gasification of feedstocks is a complex function that needs to incorporate varying levels in the processing equipment. In addition, the waste streams make thermochemical processing more expensive because they must be addressed in order for the processing to be economical.

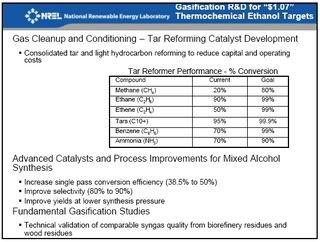

The improvement of the efficiencies of catalytic tar reforming into fuel ethanol was identified as one of the major processes that needs further advancements, as this step promises to bring considerable reductions in capital and operating costs.

At NREL, most of the work is focused on particulate removal and consolidating as many processes as possible. NREL’s recent focus on fuel synthesis is to produce biofuels from clean syngas. NREL can generate real syngas to test unit operations and study integration issues and catalyst performance issues. Once these technical challenges are addressed and the goals are achieved, major breakthroughs in biorefinery production will ensure that the capacity to produce finished products from renewable resources is available.

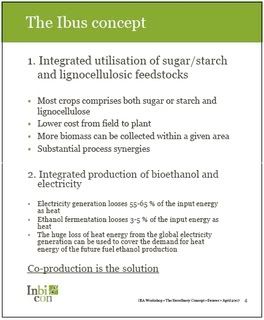

In Integrated Biomass Utilisation Systems: Best Basis for Biorefineries, Børge Holm Christensen of Inbicon A/S, Denmark, elaborated the concept of 'Integrated Biomass Utilisation Systems' (IBUS), which began by seeking alternatives for straw and ethanol, has proved to be a good concept.

The key activity of IBUS is the integrated utilisation of sugar/starch and lignocellulosic feedstocks. Most crops comprise both sugar or starch and lignocellulose. Lower cost processes use a single process and then separate the feedstock at the plant, enabling collection of more biomass within a given area and substantial process synergies.

In integrated production of bioethanol and electricity, a feedstock such as straw loses 55 to 65% of the input energy, and ethanol fermentation loses 3 to 5% of the input energy as heat. The huge loss of heat energy from the global electricity generation can be used to cover the demand for heat energy in future fuel ethanol production. The solution to these losses is co-production.

The IBUS system requires less energy and therefore has low energy costs. Use of low pressure steam from electricity generation means energy can be used without CO2 emissions. It can also recycle the by-products, does not have waste water, and does not emit volatile organic compounds. IBUS can use this pre-treatment process to enter various stages in the biorefinery.

The IBUS concept utilises the surplus steam to produce high-quality solid biofuel increases. The primary result of the EU project is the co-production of biofuels.

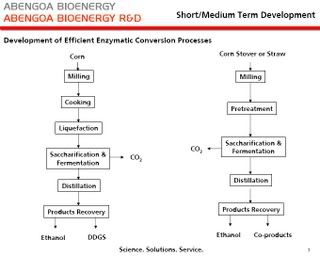

Abengoa Bioenergy, a leading biofuel & biorefinery developer and a subsidiary of Spanish group Abengoa, was represented by Quang Nguyen, who explained his company's vision on the Integration of Biomass and Cereal Ethanol Production. Abengoa is a technology company founded in Seville, Spain, and it operates in more than 40 countries. Its approach to biorefineries is to integrate starch-hybrid and biomass. It has strategic interests in producing fuels for future technologies such as hydrogen, and it considers ethanol production the basis for hydrogen fuels.

Its products and processes include: corn to milling to cooking to liquefaction to saccharification, and fermentation to distillation to product recovery. The company sees this as conversion technologies ('first generation') that will be further developed over the medium term.

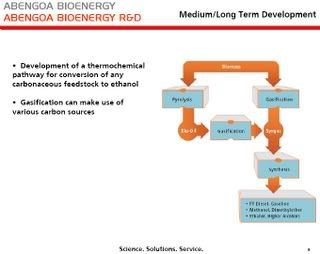

For the longer term, Abengoa is currently working on the development of a thermochemical pathway for conversion of any carbonaceous feedstock to ethanol. Current projects include a biorefinery pilot plant in York, UK, sponsored by DOE, which converts 1.5 ton/day of biomass feedstocks from corn stover, wheat straw, and switch grass. Abengoa also has a biomass ethanol commercial demonstration plant in Salamanca, Spain, supported by the European Commission, which uses 70 tons/day wheat straw as a feedstock and produces 5 million L/y ethanol.

Abengoa has various gasification, catalyst development, and ethanol reforming projects. One such project is a hybrid starch and biomass commercial plant in a conceptual design phase. Its output will be 700 tons/day, integrated with a cereal ethanol plant.

Biomass conversion challenges for Abengoa and all biorefinery plants are that biomass feedstocks are complex, varying, and bulky; feedstock collection logistics are complex; and the cellulosic biomass feedstocks are more recalcitrant than starch.

Bio-cascading

Three presentations were held during the session on 'bio-cascading'. Bio-cascading - making use of whole plants and not just their easily extractable sugars or starches - will be crucial because biomass resources are limited. Just as petroleum refineries produce gasoline as their main product, but also produce many valuable co-products, so too does the integrated biorefinery attempt to utilise the entire feedstock stream to produce biofuels and valuable co-products.

One goal is to incorporate conversion R&D and demonstrate for adoption in an existing biorefinery facility. The technical challenge is to avoid hydrolysis degradation products and use fibres in corn ethanol products. It is important that by-products from biodiesel and the sugar industry are upgraded. There are also issues of transportation and more efficient processes, which could be overcome by using cheaper and more efficient feedstocks.

Michael Ladisch of the Purdue University in the U.S. co-repsented with Gary Welch of Aventine Renewable Energy on Incorporating Conversion R&D and Testing Adaptation in an Existing Facility. They started by saying that there is a strong motivation to incorporate R&D conversion technologies and adaptation testing in existing facilities in order to reduce the dependence on oil. Another driver is the presidential mandate to reduce USA dependence on oil through the President’s ‘Twenty in Ten’ goal. NREL is working with industry, federal and state government, and universities in a collaborative effort to achieve these goals.

Ethanol, used as fuel additive as well as a stand-alone product such as E85, will help achieve the goals to reduce dependence on oil. Corn to ethanol currently accounts for 13% of all ethanol in USA. However, corn is also needed for food (both domestic and exports) and animal feed, and using it for ethanol has an impact on food costs because it places higher demand on the corn, which in turns raises its price. The amount of corn available to produce ethanol is insufficient; that, and because of its other uses, is why cellulose is needed. Corn will continue to be important, but will only account for a fraction of the production.

Thomas Willke of the Federal Agricultural Research Centre Institute of Technology and Biosystems Engineering, Germany, looked at Upgrading of By-products from Biodiesel and Sugar Industry by Bioconversion and Chemical Catalysis. The presentation offers an overview of the Federal Agricultural Research Centre Institute of Technology and Biosystems Engineering. The Centre has identified several main barriers toward the integrated biorefinery. Biomass transport, pre-treatment, conversion, production, and energy costs are all barriers that must be addressed in order to upgrade by-products from the biodiesel and sugar industries through bioconversion and chemical catalysis.

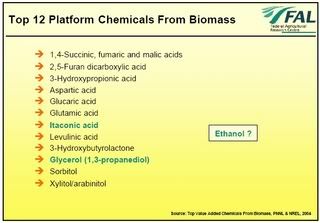

Willke explained that many of the most important platform chemicals that can be obtained from biomass can be extracted from byproducts from both the biodiesel and ethanol industries.

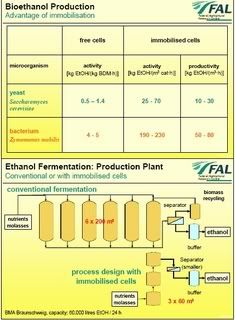

When it comes to both the production of ethanol as well as the utilisation of its byproducts, reliance on immobilised cells has many advantages over traditional fermentation (based on yeast).

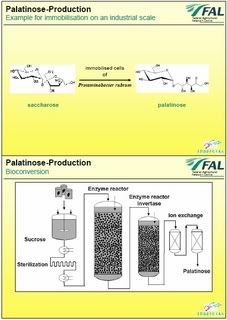

An example of the advantage of immobilisation for the extraction of green chemicals would be the production of palatinose (isomaltulose), a healthy sweetener used increasingly in the food processing industry. If ethanol production were to be based on immobilisation, production of this product could be easily integrated into the biorefinery.

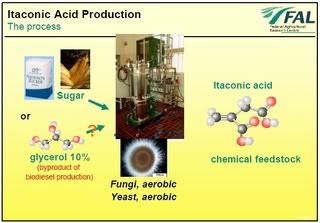

Willke zoomed in on another cascading strategy in ethanol biorefineries that can be build around the production of itaconic acid from sugars, a compound used widely in the production of polymers. Esters of itaconic acid can be used in paint, ion-exchange resin, lubricant, binder, plasticizer, sealant and molding plastics. Some other itaconic acid derivatives are used in medicine, cosmetics, lubricant, thickener, herbcide and wool modifier.

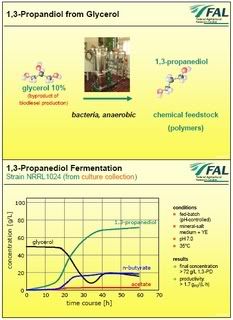

Finally, as an example of cascading byproduct use from biodiesel production, attention was given to 1,3-Propanediol which can be obtained from glycerol (glycerine). Glycerol is the major biodiesel byproduct, for which many applications are being researched (earlier post, and links there). 1,3-Propanediol finds uses in a variety of industrial products including composites, adhesives, laminates, coatings, moldings, novel aliphatic polyesters, copolyesters, solvents, antifreeze and other end uses.

Some important steps for biorefineries to reduce costs are to combine pre-treatment, conservation, and separation, such as in sugar and starch refineries, Willke concluded. The major challenge is the potential for cost reduction in biorefineries such as in transportation efficiency, more efficient processes, and cheaper and more efficient feedstocks.

Finally, Prabhakar Nair, of U.S.-based UOP LLC, discussed how to Commercialise Thermochemical R&D and Pilot Plant Results. Biofuels have had an increasingly important role in global energy demand, with 12 to 15 percent annual growth, Nair says. There are two major bio-based transport fuels: ethanol and biodiesel. USA and Brazil are primary centres for ethanol production, and Europe is the primary centre of biodiesel production. The market today is driven by subsidies to make it competitive. If the proposed mandates set by USA and the EU are adopted, they will create an additional demand for about 3 million barrels per day of renewable transport fuels by 2020.

UOP is a supplier and licensor of processing technology, which was acquired by Honeywell in 2005. UOP can apply refinery processing technology to renewable feedstocks to help the major biorefining centres in the world.

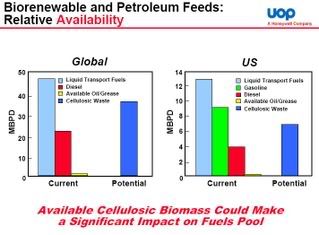

UOP thinks the availability of cellulosic biomass waste and residue streams from agriculture, forestry and industrial sectors alone can make a significant impact on the fuels pool. The potential outlined above does not take into account dedicated biomass plantations. If all these waste streams were to be converted via thermochemical processes into fuels, an equivalent of around 38 million barrels per day could be obtained.

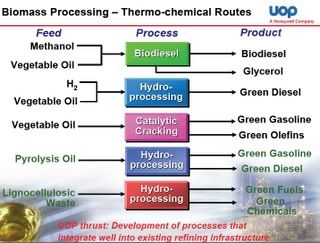

Nair outlined different possible thermochemical routes for the conversion of biomass into both diesel and gasoline alternatives, under which he included the traditional biodiesel production process known as transesterification. He did so in order to compare it with UOP's current 'green diesel' production, which is based on the hydrogenation of vegetable oils (earlier post and here).

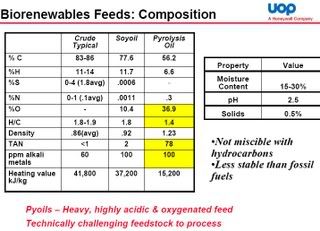

At the same time however, UOP is researching next-generation processes. On of these is based on an intermediate step consisting of the pyrolysis of biomass into bio-oil (pyrolysis oil), which can be transformed via hydroprocessing into a both green diesel and gasoline. The pyrolysis based process would allow the use of abundant lignocellulosic feedstocks. However, compared to both crude oil and vegetable oils, this pyrolysis oil is not easy to transform.

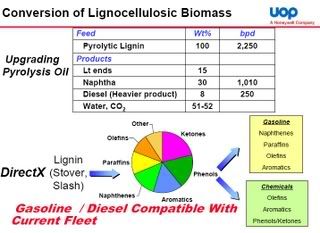

An even later generation would consist of direct conversion of lignocellulosic biomass via hydrocracking. The difference between producing biofuels via the intermediary pyrolysis step and the direct conversion process and their respective products can be seen above. Direct conversion is currently in a research phase only.

UOP notes that the current biofuels market is based on sugars and oils alone and thinks long term sustainability will require the use of lignocellulosic feeds.

Biorefinery management processes, and Iogen

This final session of the IEA Bioenergy executive committee's meeting discussed the demonstration commercial plant funded by the U.S. DOE Biomass Programme with Iogen. The Iogen plant uses straw as feedstock and will demonstrate the cellulose ethanol making process.

Another presentation was on the Project Management Center, part of DOE’s Golden Field Office. This centre manages US$1.2 billion in R&D funding for a variety of energy efficiency and renewable energy projects including biomass projects. The presenter provided an overview of the role of this office in managing the DOE biomass projects.

James Spaeth, US Department of Energy, outlined how the DOE's Project Management Center puts in efforts aimed at Managing the Biofuels Portfolio. DOE’s Office of Energy Efficiency and Renewable Energy has a dedicated field Project Management Center (PMC) at its Golden Field Office (GFO) in Colorado. The PMC function is to oversee laboratories and work with industry and academia to implement a portfolio of approximately US$1.2 billion annually, including biomass projects.

GFO uses common practices and business processes to manage projects and works from basic R&D to commercialisation. Its key functions are to implement directives from DOE headquarters into concrete solicitations and projects. GFO has the same structure as that of headquarters in that it runs solicitations and manages projects based on statements of work, including financials, technical and project milestones, and spend plans.

An important activity of GFO is working with DOE headquarters to enact sections of USA Energy Policy Act of 2005. GFO has played a major role in the selection and management of the activities conducted in the Implementation of Section 932, which calls for financial support to commercialise six biorefinery plants. In addition, GFO has begun to examine how to implement the 942 reverse auction. These efforts will jumpstart cellulosic ethanol production in USA.

The Iogen Story was presented by Maurice Hladik, of Iogen, Canada. Iogen is the well known producer of enzymes used to convert lignocellulosic biomass into ethanol and has been active in producing the biofuel since the 1970s. It has a variety of partners, including Shell and Goldman Sachs.

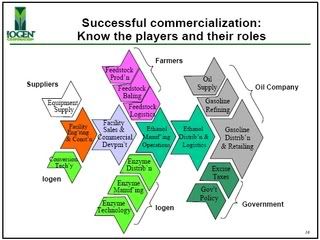

According to Iogen, crucial for the successful commercialisation of cellulosic ethanol refineries, is to know one's correct position in the complex landscape of players and policies, and to form partnerships and synergies between these players so that the entire industry becomes more efficient, on all fronts.

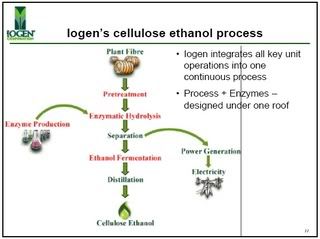

Iogen’s demonstration plant exclusively uses straw and is a successful example of an operating demonstration facility. The plant uses a cellulose ethanol process and integrates all key unit operations into one continuous process. Iogen’s enzymes are designed around the process, and the process is designed around the enzymes. The company believes that cellulose ethanol could displace more than 30% of the United States' present petroleum consumption.

Picture opening this article: The fermenter of Iogen's biorefinery in Ottowa, the world's first cellulosic biomass conversion facility. Courtesy: Iogen Corp.

References:

All images are taken from the respective presentations.

IEA Bioenergy: The Biorefinery Concept - workshop held in conjunction with ExCo59 in Golden, USA on 25 April 2007.

--------------

--------------

BioDiesel International AG has acquired 70 per cent of the shares in Lignosol, a Salzburg based company that is making promising progress in Biomass-to-Liquids conversion techniques. The purchase price is in the single-digit million Euro range.

BioDiesel International AG has acquired 70 per cent of the shares in Lignosol, a Salzburg based company that is making promising progress in Biomass-to-Liquids conversion techniques. The purchase price is in the single-digit million Euro range.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home