Scientists propose cold storage of CO2

When it comes to fighting climate change, bioenergy has one major advantage over carbon 'neutral' renewables such as solar, wind, geothermal or tidal energy: it can be used as the foundation stone of a radical carbon negative energy system. Scientists call such a system 'Bio-Energy with Carbon Storage' (BECS) (earlier post) and it consists of the following 'geo-engineering' strategy: plant energy crops at strategic locations around the globe; allow the biomass to capture CO2 from the atmosphere; use the crops as a biofuel in coal or biomass power plants; and then capture and store the CO2 emissions underground. The result is a carbon-negative cycle, which can take us back to pre-industrial CO2 levels in a matter of decades.

When it comes to fighting climate change, bioenergy has one major advantage over carbon 'neutral' renewables such as solar, wind, geothermal or tidal energy: it can be used as the foundation stone of a radical carbon negative energy system. Scientists call such a system 'Bio-Energy with Carbon Storage' (BECS) (earlier post) and it consists of the following 'geo-engineering' strategy: plant energy crops at strategic locations around the globe; allow the biomass to capture CO2 from the atmosphere; use the crops as a biofuel in coal or biomass power plants; and then capture and store the CO2 emissions underground. The result is a carbon-negative cycle, which can take us back to pre-industrial CO2 levels in a matter of decades.The viability of this geo-engineering option depends on the development of reliable carbon capture and storage (CCS) techniques. The coal industry is investing heavily in CCS and has been looking at storage sites as diverse as salt tables, depleted gas and oil fields, and warm sediments in oceans. But doubts remain over the long-term stability of this type of sequestration; the risk of CO2 leakage remains a major obstacle.

Cold storage

Researchers from the University of Leicester and the British Geological Society (BGS) have now come up with a new proposition: CO2 can be stored as a liquid or a solid in huge, cool underground geological aquifers or reservoirs and stay there harmlessly for many thousands of years. They have already identified sites in Western Europe that would be suitable. Their research is to be published in the journal Planet Earth.

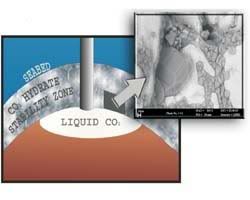

PhD research student Ameena Camps, is working with Professor Mike Lovell at the University's Department of Geology and with Chris Rochelle at BGS, investigating the storage of CO2. Storing the gas in a solid form as a gas hydrate, or as a pool of liquid CO2 below a cap of hydrate cemented sediments, is believed to offer an alternative method of geological sequestration to the current practices of storage in warm, deep sediments in the North Sea.

Recently quoted in Planet Earth Ameena Camps explained: "Hydrates (also known as clathrates) are ice-like crystalline minerals that look like normal ice and form when gas and water freeze together at low temperature and high pressure. They are made of a cage of frozen water molecules with the gas molecules trapped inside."

Although gas hydrates were first discovered two centuries ago, the possible use of carbon dioxide hydrate as a means to help resolve problems of global climate change, and of naturally occurring methane hydrate as a future source of energy, have only recently been suggested:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: climate change :: carbon dioxide :: CO2 :: carbon capture and storage :: CCS :: hydrates ::carbon negative :: Bio-Energy with Carbon Storage ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: climate change :: carbon dioxide :: CO2 :: carbon capture and storage :: CCS :: hydrates ::carbon negative :: Bio-Energy with Carbon Storage :: Laboratory experiments carried out as part of Ameena Camps' PhD project have indicated that carbon dioxide hydrate should form stable structures in sediments under oceans. By employing geophysical techniques and computer modelling, Ms Camps has identified a number of sites in Western Europe with the potential to store carbon dioxide by this method.

She is also exploring further implications of her research that may benefit geologists' understanding of the stability of deep submarine slopes and contribute to improvements in global water supplies through further understanding of desalination processes.

Professor Mike Lovell, of the University of Leicester Department of Geology commented: "Ms Camps' work is at the forefront of gas hydrate research, and has produced some very exciting results, highlighting the importance of investment in further studies of hydrates.

"Investigations of natural methane hydrates will help our understanding of their role as a natural hazard, while carbon dioxide hydrates are a potential sink for greenhouse gas emissions. This work also has application in other fields such as space research into hydrates on other planetary bodies."

A quick look at the rationale behind the research

Why should CO2 be captured and stored?

Approximately one third of all CO2 emissions due to human activity come from fossil fuels used for generating electricity, with each power plant capable of emitting several million tonnes of CO2 annually. A variety of other industrial processes also emit large amounts of CO2 from each plant, for example oil refineries, cement works, and iron and steel production. These emissions could be reduced substantially, without major changes to the basic process, by capturing and storing the CO2. Other sources of emissions, such as transport and domestic buildings, cannot be tackled in the same way because of the large number of small sources of CO2.

CO2 capture

Capturing CO2 can be applied to large point sources, such as large fossil fuel or biomass energy facilities, major CO2 emitting industries, natural gas production, synthetic fuel plants and fossil fuel-based hydrogen production plants. Broadly, three different types of technologies exist: Post-combustion, pre-combustion, and oxyfuel combustion.

In post-combustion, the CO2 is removed after combustion of the fossil fuel - this is the scheme that would be applied to conventional power plants. Here, carbon dioxide is captured from flue gases at power stations (in the case of coal, this is sometimes known as "clean coal"). The technology is well understood and is currently used in niche markets.

The technology for pre-combustion is widely applied in fertilizer, chemical, gaseous fuel (H2, CH4), and power production. In these cases, the fossil fuel is gasified and the resulting CO2 can be captured from a relatively pure exhaust stream.

An alternate method, which is under development, is chemical looping combustion. Chemical looping uses a metal oxide as a solid oxygen carrier. Metal oxide particles react with a solid, liquid or gaseous fuel in a fluidized bed combustor, producing solid metal particles and a mixture of carbon dioxide and water vapour. The water vapor is condensed, leaving pure carbon dioxide which can be sequestered. The solid metal particles are circulated to another fluidized bed where they react with air, producing heat and regenerating metal oxide particles that are recirculated to the fluidized bed combustor.

CO2 transport

After capture, the CO2 must be transported to suitable storage sites. This is done by pipeline, which is generally the cheapest form of transport, by ship or by land transport when no pipelines are available. Both methods are currently used for transporting CO2 for other applications.

Having captured the CO2 it would need to be stored securely for hundreds or even thousands of years, in order to avoid it reaching the atmosphere. Major reservoirs, suitable for storage, have been identified under the earth's surface and in the oceans. Work to develop many of these options is in progress.

Underground storage of CO2 has taken place for many years as a consequence of injecting CO2 into oil fields to enhance recovery. CO2 is being deliberately stored in a salt water reservoir under the North Sea for climate change reasons. Sleipner is located in the North Sea where Norway's Statoil strips carbon dioxide from natural gas with amine solvents and disposes of this carbon dioxide in a saline formation. The carbon dioxide is a waste product of the field's natural gas production and the gas contains more (9% CO2) than is allowed into the natural gas distribution network. Storing it underground avoids this problem and saves Statoil hundreds of millions of euro in avoided carbon taxes. Sleipner stores about one million tonnes CO2 a year. The Weyburn project started in 2000 and is located in an oil reservoir discovered in 1954 in Weyburn, Southeastern Saskatchewan, Canada. The CO2 for this project is captured at the Great Plains Coal Gasification plant in Beulah, North Dakota which has produced methane from coal for more than 30 years. At Weyburn, the CO2 will also be used for enhanced oil recovery with an injection rate of about 1.5 million tonnes per year. The third site is In Salah, which like Sleipner is a natural gas reservoir located in In Salah, Algeria. The CO2 will be separated from the natural gas and re-injected into the subsurface at a rate of about 1.2 million tonnes per year.The potential capacity for underground storage is large but not well documented. Other geological storage schemes are under development and plans to monitor them are well advanced.

CO2 storage as a liquid and hydrate is a more novel method of geologically sequestering CO2 extracted from flue gases. CO2 would be injected into depleted/exhausted reservoirs and/or aquifers using similar infrastructure used in the North Sea Sleipner gas field, but injection would take place into sub-seabed sediments below deep waters at colder temperatures, where carbon dioxide is in its liquid phase. By injecting below the hydrate stability zone in cold deep sediments, if any upward migration occurred the stored liquid would enter the hydrate stability zone, forming CO2 hydrate, and trapping the underlying liquid. Storage as a liquid and hydrate would allow greater volumes of gas to be trapped within these deep water reservoirs (when compared with supercritical storage such as at Sleipner), and could remain trapped for thousands of years.

More information:

Eurekalert: Cold storage solution for global warming? - Feb. 7, 2007.

CSC UK: What is carbon capture and storage?

Biopact: Abrupt Climate Change and geo-engineering the planet with carbon-negative bioenergy - Dec. 21, 2006.

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home