An in-depth look at biofuels from algae

Over the past few years, several companies have issued press releases about technologies they have developed to produce biofuels from algae. The claims in these stories are that algae yield 'enormous' amounts of biomass that can be turned into liquid fuels at low cost. Most of the projects involve the use of closed photobioreactors, in which the micro-organisms are grown in a controlled manner by feeding them CO2 and nutrients. Sadly, after decades of development, none of those projects have ever demonstrated the technology on a large scale, let alone over long periods of time. This is why it is time to have a look at the possible reasons as to why algae biofuels are being talked about, but don't seem to get off the ground.

Over the past few years, several companies have issued press releases about technologies they have developed to produce biofuels from algae. The claims in these stories are that algae yield 'enormous' amounts of biomass that can be turned into liquid fuels at low cost. Most of the projects involve the use of closed photobioreactors, in which the micro-organisms are grown in a controlled manner by feeding them CO2 and nutrients. Sadly, after decades of development, none of those projects have ever demonstrated the technology on a large scale, let alone over long periods of time. This is why it is time to have a look at the possible reasons as to why algae biofuels are being talked about, but don't seem to get off the ground.The biofuel potential of algae has been the object of considerable research efforts in the past. Both in Europe (France and Germany), Japan and the US, scientists have been working on algae systems since the 1950s and especially since the oil crisis of the 1970s. One program stood out, because it was so comprehensive. This is the so-called "Aquatic Species Program" (ASP), which ran from 1978 to 1996 under the US National Renewable Energy Laboratory (NREL), funded by the Office of Fuels Development, a division of the US Department of Energy. The program's conclusions offer a handy guideline for those of us who want to explore the challenges and opportunities of producing biofuels from algae.

The focus of this program was to investigate high-oil algaes that could be grown specifically for the purpose of wide scale biodiesel production. The research began as a project looking into using quick-growing algae to sequester carbon in CO2 emissions from coal power plants. Algae had already been used in experiments to manage waste water and were found to make good substrates for biogas production, even though the sludge they fed on yielded more biogas. Noticing however that some algae have very high oil contents, the project shifted its focus to growing algae for another purpose - producing biodiesel. Some species of algae were supposed to be ideally suited to biodiesel production due to their high oil content (between 10 and 50%, depending on many different factors), and fast growth rates in laboratory situations. But after two decades of fundamental research and large-scale trials, the results of the ASP have been a mixed bag.

The following is an in-depth look at the conclusions of the different projects carried out under the program. All quotes are taken from "A look back at the U.S. Departmenf of Energy's Aquatic Species Program" [*.pdf], the close-out document that was written after the program was terminated in 1996.

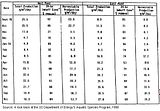

For readers who want a shortcut: Table 1 offers a quick overview of the results of all the studies under the ASP, as well as those of some earlier research on which the program drew (click to enlarge). Note that the results on biomass yields in the table only refer to yields that were actually obtained in the field, not to projected, desired or predicted yields.

For readers who want a shortcut: Table 1 offers a quick overview of the results of all the studies under the ASP, as well as those of some earlier research on which the program drew (click to enlarge). Note that the results on biomass yields in the table only refer to yields that were actually obtained in the field, not to projected, desired or predicted yields.Our overview includes a look at the most common problems and challenges encountered during the program (low yields, unstable algae cultures, harvesting difficulties, pond design, the impractability of photobioreactors) and at the results of the separate experiments conducted from the late 1970s to the early 1990s. We compare the biomass yields of ordinary terrestrial tropical energy crops with those of algae and analyze some basic risks involved in both biomass production systems. Finally, we have a look at recent developments in the production of gaseous fuels (biohydrogen and biogas) based on algae.

Limited success with engineering algae

The ASP's original aim of genetically manipulating algae so that they produce more lipids did not yield any significant results. The researchers discovered a lot of information about the genetics and environmental factors that play a role in the biology of different algae species, but they failed to identify the magic 'lipid trigger' they were looking for. The ASP concluded that:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: biogas :: biodiesel :: biohydrogen :: algae :: cyanobacteria :: diatoms :: energy balance :: life-cycle analysis :: energy crops :: tropical ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: biogas :: biodiesel :: biohydrogen :: algae :: cyanobacteria :: diatoms :: energy balance :: life-cycle analysis :: energy crops :: tropical ::"Although much remains to be done, significant progress was made in the understanding of environmental and genetic factors that affect lipid accumulation in microalgae, and in the ability to manipulate these factors to produce strains with desired traits. The evidence for a specific lipid trigger is not overwhelming." [page 142]

However, another, non-genetic way of increasing the amount of lipids within the cells was discovered. It consisted of depriving the algae of certain nutrients:

"Interpreting exactly what is happening in the nutrient-deprived cells is difficult, particularly when cells are starved for N, as the lack of an important nutrient is likely to produce multiple and complex reactions in a cell. However, lipid accumulation in some algal species can be induced by nutrient limitation." [142]

Even though this technique did increase the lipid content of some of the micro-organisms, it also resulted in a decrease of the overall biomass productivity of the algae. The net-result in terms of total lipid production was negative:

"One of the most important findings from the studies on lipid accumulation in the microalgae is that, although nutrient stress causes lipid to increase in many strains as a percentage of the total biomass, this increase is generally accompanied by a decrease in total cell and lipid productivity." [143]

Finally, preliminary experiments were also performed within the ASP to use the knowledge obtained on the genetic transformation system in order to

"introduce genes into the algal cells, with the goal of manipulating lipid biosynthesis. Additional copies of the ACCase gene were introduced into cells of C. cryptica and N. saprophila. Although ACCase activity was increased in these cells, there was no detectable increase in lipid accumulation." [144]

The program was terminated before further research into this path was undertaken. Given the rapid developments in biotechnology (a decade has passed since the ASP was ended), we think it is very likely that ideal algae can be engineered in the future, even though the challenges remain high.

Such an ideal type would have to have the following properties:

1. it should have a high and constant lipid content;

2. one has to be able to grow the micro-organism continuously (the problem of the stability of algae cultures);

3. it should have a high photosynthetic efficiency resulting in high and constant biomass productivities;

4. it should be capable of withstanding seasonal climatic differences and daily changes in temperatures.

5. the physical nature of the 'super' algae (especially its size) would have to be such that it is easily harvesteable by membranes (if the species is too small, high-strength and durable harvesting membranes have to be designed that have to be able to withstand fouling and water pressure drops; in the late 1970, such membranes were deemed to be too costly) or it would have to be a type that easily flocculates so that harvesting can occur without too much losses and without the need for costly flocculants (see below).

All of the above are common problems associated with alga-culture that were identified during the ASP.

Photobioreactors: dismissed as too costly and impractical

The Aquatic Species Program experimented with closed photobioreactors for a while, but quickly dismissed them as being too impractical and costly. It therefor concentrated on growing algae in open ponds from the start, an effort it pursued over the decades that followed.

"The Japanese, French and German governments have invested significant R&D dollars on novel closed bioreactor designs for algae production. The main advantage of such closed systems is that they are not as subject to contamination with whatever organism happens to be carried in the wind. The Japanese have, for example, developed optical fiber-based reactor systems that could dramatically reduce the amount of surface area required for algae production. While breakthroughs in these types of systems may well occur, their costs are, for now, prohibitive—especially for production of fuels. DOE’s program focused primarily on open pond raceway systems because of their relative low cost." [5]

At the end of the 1970s (when oil prices hit all time highs; US$80 per barrel in 2004 dollars), one last photobioreactor project involving the use of a fibre-optic lighting system was abandoned very soon:

"Another biophotolysis project tested an optical fiber system for diffusing solar light into algal cultures, thereby overcoming the light saturation limitation to photosynthetic efficiencies. This was shown to be impractical and was abandoned after only some very initial work." [161]

At the time, Japanese scientists started working on the same fibre-optic lighting technology, but this effort yielded no major breakthroughs. Fibre-optics were thought to offer a solution to the problem of light saturation limits experienced in closed photobioreactors. A theoretical advantage of such reactors is the limited amount of space they need; algae move through them in a controlled flow, so that they recieve an optimal amount of light. But it quickly became apparent that this theory doesn't work out in practise.

If reactors are designed in the form of large tubes or spheres, the algae located at the center do not receive enough light. So scientists introduced fibre-optic wires at the center of the reactor, which continuously emit light. The kinetics of the algae would then be finetuned so that all of them circle around the surface of the reactor (where they receive ambient light) and near the center, where they receive light from the fibre-optic wires. Obviously, this was quite a costly affair, compared to simply growing algae on a horizontal plane (in shallow ponds) where they can make use of sunlight. Like ordinary terrestrial crops.

In the end, the ASP decided to take the latter route, and abandoned photobioreactor research alltogether. Instead, it started designing open ponds, to be located in the open air, in sunny deserts and other locations that receive a lot of sunshine (like Hawaii). From then on, the argument that algae take up "less space to grow" than ordinary crops, no longer held.

Full life-cycle analysis required

Taking into account the ASP's experience with photobioreactors, we should stress that current announcements surrounding this technology are not very transparent nor complete. Advocates of algae biofuels often look at the biomass productivities of algae in closed photobioreactors, and compare those to the yields of energy crops or to algae grown in open ponds. But there is more to bioenergy than mere crop yields. Both from an economic as well as from an environmental point of view, the entire life-cycle of the biofuels must be analysed.

Press releases from algae-biofuel companies never disclose any information on the actual energy balance, the greenhouse gas balance and the costs involved in manufacturing and operating photobioreactors. They don't because it is their obvious weak point. As one analyst (Jonas Van Den Berg) once said: "growing algae in reactors or in plastic ponds is like growing sugarcane in greenhouses, it makes no sense." As the following analyses in this essay will show, there is some truth to this observation.

There are many techniques and problems associated with life-cycle studies of biofuels (earlier post). Depending on the chosen parameters (system boundaries and byproduct credits), results will differ. But in the case of closed photobioreactors, it would be legitimate to use the technique used by an often quoted scientist like David Pimentel (Cornell University), who made a comprehensive energy balance analysis of ethanol, and who used a very broad "system boundary" in his study. For example, he included the energy inputs required to manufacture farm machinery that will be used to harvest the corn.

It would be interesting to make a similar life-cycle analysis for photobioreactors. The Aquatic Species Program did not do this explicitly, but we guess that when it said reactors are "too costly", it hinted at the overal life-cycle of the technology. Photobioreactors are made of resources that require a lot of energy to make. Steel, aluminum, polymers, glass, shaped in special forms (spheres and tubes). A lot of energy goes into (building the machines needed for) mining the raw resources (iron, aluminum ore, petroleum for the polymers, and so on). The ores then have to be transported to processing plants where another amount of energy is required to smelt and cast them. The finished pieces then have to be brought together (requires transport energy) and assembled. All this happens before any biofuel has been produced.

When the reactor is in place, it needs to be heated and cooled in order to operate efficiently during cold winter and hot summer months. This too requires a considerable amount of energy. Without heating, algae cultures die or become extremely unproductive (the ASP showed that cultures grown in open ponds yield as low as 2g/m² of biomass per day (on a yearly basis this equals to around 7,3 metric tons) during winter months.

Furthermore, the ASP showed that there is a fine balance between the optimal kinetics of the algae (the speed at which they move through a system in order to receive enough light) and the energy inputs needed to achieve this balance: in several experiments, the costs of keeping the algae flowing (by pumping the medium in which they grow), exceeded the energy the algae produced. In photobioreactors, this same observation holds. Some reactors consist of vertically, diagonally and horizontally stacked tubes through wich the algae are circulated; if under the ASP's horizontal pond conditions, the energy balance already was negative in some experiments (speeds >30cm/s), it is not unreasonable to assume that it will be negative in such complex reactors where the algal medium has to be pumped several metres high through vertical tubes.

Furthermore, the ASP showed that there is a fine balance between the optimal kinetics of the algae (the speed at which they move through a system in order to receive enough light) and the energy inputs needed to achieve this balance: in several experiments, the costs of keeping the algae flowing (by pumping the medium in which they grow), exceeded the energy the algae produced. In photobioreactors, this same observation holds. Some reactors consist of vertically, diagonally and horizontally stacked tubes through wich the algae are circulated; if under the ASP's horizontal pond conditions, the energy balance already was negative in some experiments (speeds >30cm/s), it is not unreasonable to assume that it will be negative in such complex reactors where the algal medium has to be pumped several metres high through vertical tubes.In short, comparing the biomass productivities of algae and their resulting energy content without taking into account the entire energy balance, is a futile exercise. Journalists and the media should not forget this. At the Biopact, we also think that this is one of the reasons why so many algae projects issue a press release, but never actually implement their technology on a large scale. If closed photobioreactors work and succeed in delivering cheap biofuels, then all the better for us. But if they don't, we should have the courage to say so too.

NREL's ASP research abandoned photobioreactors alltogether and instead focused on the development of algae farms in desert regions, using shallow saltwater pools for growing the algae. Using saltwater eliminates the need for desalination, but could lead to problems as far as salt build-up in ponds. Building the ponds in deserts also leads to problems of high evaporation rates and temperature control (at night, it can get very cold and heating ponds would be very costly). Moreover, during winter months, biomass productivities declined sharply, lowering the overal biomass yields per year. Harvesting the algae posed engineering challenges. Finally, another recurring problem was keeping the algae cultures stable. Cultures that performed well under laboratory conditions were often lost in the field trials, because they were invaded by stronger algae; the experiments were often halted and new cultures had to be reintroduced into the ponds.

All these challenges are nicely illustrated in the separate large-scale experiments that were carried out from the late 1970s to the early 1990s. Let us have a cursory look at them.

STUDIES PRECEDING THE ASP

Species Control in Large-Scale Algal Biomass Production (1976)

From the very beginning, in the 1950s up until today, the problem of the stability of algae cultures in open ponds has not been resolved. In a first series of experiments, aimed at growing algae for waste-water treatment in open ponds, there was a consistent gap between the stability of laboratory cultures and the instability of cultures grown in open ponds.

This 'Species Control' project addressed this problem and at the same time looked at potential harvesting technologies. Because the dominant algal species found in a pond could range from small unicellular to large colonial or filamentous species, harvesting of the algae for biomass conversion would require a universally applicable harvesting technology, such as centrifugation or chemical flocculation, to enable the recovery of any algal type. However, these processes proved to be very expensive.

If, however, algal species could be controlled in the ponds, then filamentous microalgae species might be grown that would be easier and cheaper to harvest using microstrainers. Microstrainers, which are rotating screens (typically 25 to 50 µm openings) with a backwash, are already widely used for removing filamentous algae, mainly filamentous cyanobacteria (blue-green algae) from potable water supplies.

Thus, the first objective of this project, initiated in 1976, was to investigate how to selectively cultivate filamentous microalgal species in waste treatment ponds

"Both at short and long retention times the algal cultures invariably became unharvestable with microstrainers. Intermediate hydraulic retention times selected for larger colonial algal species that were more readily harvestable. However, long retention times also resulted in low productivities. There was an optimum residence time, which varied with depth of the culture and climatic variables that selected for harvestable cultures. However, biomass recycling was only marginally effective in improving biomass harvestability by microstraining. " [148]

Problems were encountered with zooplankton grazing off the algal cultures. Coarse (150-µm) screens did not effectively remove the grazers. Shorter retention times reduced grazer pressures, but also made the cultures less harvestable by microstrainers. In all the ponds, the Scenedesmus species dominated in the winter and spring, and then was replaced with Microactinium. Loss of dominance correlated with the breakup of the colonies, which may have been related to zooplankton grazing.

"The best productivity was 13.4 g/m2/d, during a 10-month period, irrespective of harvest efficiency. For the most harvestable pond, productivity was only 8.5 g/m2/d (of which only 7.2 g/m2/d was harvested by the microstrainers). Clearly, optimizing for productivity and harvestability required quite different operating conditions. It was concluded that the use of microstrainer harvesting and biomass recycling was unlikely to lead to both a high algal productivity and effective harvesting process." [152]

Large-Scale Freshwater Microalgal Biomass Production for Fuel and Fertilizer (1977-1979)

Both microstrainer harvesting and biomass recycling were seen as unfeasible harvesting strategies, but researchers kept experimenting with the techniques, only to abandon them relatively soon:

"Initially the approach to establish microstrainable cultures using the 12-m2 ponds, continued to be investigated. Essentially the same results as before were obtained: detention time was found to be the key environmental variable determining algal colony size (but not necessarily species composition) and a negative correlation was found between numbers of algal grazers and the large colonial algal types easy to harvest with microstrainers. Apparently the grazers preferentially consumed the smaller algae. Overall, the harvestability results with the microstrainers continued to be poor, so this line of research was abandoned during the initial period of this project." [156]

They then focused on another technique: harvesting after bioflocculation. Bioflocculation refers to the tendency of normally repulsive microalgae to aggregate in large flocs, that then exhibit a rather high sedimentation velocity. The mechanisms of bioflocculation involve extracellular polymers excreted by the algae. Once the algae have flocked together, they can be harvested.

The bioflocculation research zoomed in on a “phase isolation” process, in which the algal cells were allowed to spontaneously settle when sewage inflow was stopped. Although generally long times were required for this settling process (2-3 weeks), it was decided to investigate this general phenomenon of “bioflocculation” in high rate ponds. The process involved removing the algae from the paddle wheel-mixed ponds and placing them in a quiescent container, where they would spontaneously flocculate and rapidly settle.

There are several apparently distinct mechanisms by which algae flocculate and then settle, including “autoflocculation”, which is induced by high pH in the presence of phosphate and divalent cations (Mg2+ and Ca2+), and flocculation induced by N limitation.

Settling tests were carried out with the cultures from the 12-m2 ponds. As with microstrainer harvesting, detention time and mixing velocity were the most important variables in promoting a bioflocculating culture. The rather rapid settling of many of the cultures was very encouraging. Also, the initial experiments with the 0.25-ha pond demonstrated a fairly rapid

"Bioflocculation [being] established as the method of choice for algal harvesting, as it seemed to be achievable even with high productivity cultures. Culture settleability was routinely determined during all the experiments with the high rate ponds." [157]

Interesting yield data

Table 2 summarizes productivity, settleability and harvesteability of algae grown for more than 1 year in the two 0.1-ha ponds (click to enlarge).

Table 2 summarizes productivity, settleability and harvesteability of algae grown for more than 1 year in the two 0.1-ha ponds (click to enlarge).These results were the only ones so far for algae grown during all monhts of the year. They show the sensitivity of the micro-organisms to changes in temperature, with yields in winter and spring months declining to very low levels (lowest: 2.6g/m²/ha).

The average gross biomass productivity was maximum 14g/m²/day (51.1 tons per hectare per year), and minimum 12g/m²/day (43.8 tons per hectare per year), of which some 90% could be harvested.

The difference in harvestable biomass yields between algae grown in large (0.1 hectares) and small (12m²) ponds was small: both small ponds obtained an average yield of 13g/m²/day (even though they were only used to grow algae for a period of 10 months, excluding the two coldest months), the two large ones 14g/m²/day and 12g/m²/day respectively.

The numbers from these trials, showing a yield per hectare per year, allow us to make a comparison with ordinary terrestrial energy crops (see below).

Membrane harvesting project (1978)

Professor Harry Gregor at Columbia University was funded for 2 years to develop membrane systems for cross-flow filtration harvesting of microalgae. However, the membranes available at the time, the pressure drops required, and the fouling problems encountered made this approach impractical.

Ryther and Goldman (late 1970s)

At Woods Hole Oceanographic Institutions, Drs. John Ryther and Joel Goldman carried out extensive research on microalgae cultivation in outdoor ponds on mixtures of seawater-secondary sewage effluent. When Dr. Ryther relocated to the Harbor Branch Oceanographic Foundation in Florida in the late 1970s, he was supported by DOE and later the ASP for the production of freshwater plants (water hyacinths, etc.) and seaweeds, as well as for microalgae culture collection work. Dr. Goldman also wrote a review on the theoretical and practical aspects of microalgae cultivation under contract with the US Department of Energy.

"One conclusion was that the productivity of microalgae systems would be limited, because of the light saturation effect and other factors, to below 50 tons/ha/yr." [161]

A yield of 50 tons/ha/year is considerably below average yields of ordinary tropical energy crops (see below).

MICROALGAL MASS CULTURE: THE ASP'S OWN RESEARCH

After these previous studies and field trials, the ASP tried to improve upon both the harvesting process as well as on keeping algae cultures stable, and embarked on its ambitious program that consisted of:

"extensive work on [algae] strain isolation, selection, characterization, etc., carried out by the ASP [which] was used to a significant extent by the field projects, through the testing of a number of the isolates in algal mass cultures." [162]

But the gap between laboratory and field results kept appearing throughout the program:

"Unfortunately, the laboratory-level screening protocols had, in hindsight, relatively little predictive power for the ability of the strains to dominate and perform in outdoor ponds. Similarly, the laboratory work on the biochemistry, genetics and physiology of lipid biosynthesis, was difficult to apply to the goal of increasing lipid productivities in outdoor systems. Greater integration of laboratory and outdoor R&D is a challenge for any future microalgae R&D program." [162]

Despite this disconnect, the ASP went ahead an initiated two outdoor projects in 1980, one in California using a paddle wheel-mixed raceway pond design (“high rate pond,” [HRP]), and another in Hawaii. The Hawaii project was to demonstrate a patented algal culture system, invented by then-ASP program manager, Dr. Larry Raymond (1981). This “Algal Raceway Production System” (ARPS) used very shallow flumes.

HAWAII, 1980-1987

This first major project made use of Dr Raymond's patented ARPS, a complex 48m² raceway pond, which was expected to yield high and consistent productivities with strains of P. tricornutum.

One difficulty noted in the laboratory experiments was the low cell densities achieved, compared with the original reports by Raymond for the ARPS system. Researchers tried to increase cell density by increasing the pond depth to 0.6 m, rather than 0.1 m as proposed by Raymond. This resulted in other problems (low cell density, shading-see below), and the depth was again reduced to 30 cm.

Laws later reported on initial results with the 48-m2, 0.6-m deep, airlift-mixed flume system. Cell densities were much lower than predicted, likely because of the great depth of the culture, which was later reduced.

The second year of this project emphasized the use of “flashing light to enhance algal mass culture production”. The basic idea was that a “foil array” in the pond culture would generate a vortex that would create organized mixing in the ponds, expected to result in exposure of the cells to regular dark-light cycles.

Based on data in the literature, this effect would be predicted to increase overall productivity. These a priori arguments were not supported by the algal physiological literature (the flashing light productivity enhancements are observed at much shorter time constants), and neither were the hydraulic arguments plausible (organized mixing would be seen only in a small fraction of the pond volume). However, the key issue here is not the theory but the actual experimental results.

"From November 1981 to January 1982, an average productivity of only about 3.3 g/m2/d was recorded for the 50-m2-flume reactor, a very low value for Hawaii, even in winter. After installation of the foils, productivities, from February to March 1982, increased to about 11 g/m2/d." [166]

One observation was infestation of the culture by algal predators, which could have been one reason for the rather large variability in productivities observed during this operation. However, day-to-day variability in productivities is a fact of outdoor pond microalgae cultivation, even in the best of cases.

During the third year, a set of variables was tested and the researchers concluded that “by far the most significant factor affecting biomass production” was culture depth, arguing that the “self-shading effects were more than offset by higher areal standing crops.” This was a rather puzzling conclusion as it is contrary to both theory and experience, which assumes that, everything else being equal, depth should not affect productivity. No actual productivity data were reported.

The fourth year switched algae species, because “the fact that a given species grows well in the laboratory is no guarantee that it will perform well in an outdoor culture system.” One reason the project switched to different algal species was that the P. tricornutum strain used in the experiments described above was quite sensitive to even moderate (above 25°C) temperatures, and required temperature control (cooling) of the reactors. A Platymonas sp. was thus tested without temperature control in the outdoor flumes, at several dilution rates and maximal pH levels of 7 to 8. This strain showed a maximum productivity of about 26 g/m2/d, about the same as observed with P. tricornutum with temperature control.

Note that, even though no energy inputs were reported, using the tricornutum strain required continuously cooling the reactors, an energy intensive operation.

During the fifth year, research was once again directed toward the study of more thermotolerant species. Algal strains collected by the ASP researchers in the southwestern United States were evaluated using different types of water. Several species, including Platymonas sp. (used previously), Amphora sp., C. gracilis, and Boekelovia sp. were grown in the two water types, each at two salinities and at four temperatures (25° to 32°C), with the data reported as the number of doublings per day, making it difficult to compare the actual biomass productivity with previous and later results.

One interesting, but unexplained, observation was that at higher temperatures there was a consistent shift, among all four algae, of maximum doubling rates to the higher salinity waters. The small outdoor flumes were used to test this cultivation strategy. The cultures were diluted each third day, to a concentration of 2 x 106 cells. The results were “consistent with those of earlier studies,” with solar conversion (PAR) efficiencies close to 10% (5% of total solar). The C. gracilis species was also tested, though at a 2-day dilution rate (requiring a one per day doubling time), with somewhat lower efficiencies (8%), though still rather high productivities. Also, Tetraselmis suecica was cultivated in the ponds with good results. Over a 78-day cycle, in spring 1984 and summer 1985, productivity was 37+5 g/m2/d, with a corresponding PAR efficiency of 9.1%.

Research during year 6 elaborated on the two key findings mentioned earlier: effects of a 3-day dilution interval and of the foil arrays. The effects of foil arrays were tested over a 12-month period in the 48-m2 flume with Cyclotella sp., a diatom, which, like Chaetoceros, is a good lipid producer. The experiment involved alternatingly operating the pond with and without the foils for 2-week periods. The presence of foils increased productivity by almost a third, similar to the prior experiments.

The dilution effect was investigated with T. suecica, also in the 48-m2 flume, with similar results as before, in terms of both overall and maximal 3rd day productivity. However, solar conversion efficiencies were lower than observed in previous years, perhaps due to the approximately 3°C higher temperature during this year, compared to the previous one. The author speculated that this could have been close to the maximal permissible temperature for growth of T. suecica, and thus resulted in lower productivities.

However, the effect of dilution interval on production in the 48.4-m2 flume was somewhat puzzling. These findings were a subject of considerable discussion and controversy. One possible explanation was the measurement of actual biomass density, which varied from about 27-28 g/m2 after dilution, to 80, 140, and 160 g/m2 for the 2-, 3-, and 4-day dilutions periods, respectively. However, this was considered an “unlikely” explanation. Indeed, the highest productivity was observed on day 3, with a steep decline on day 4. However, 4-day cycle cells still had lower productivity on day 3. Some “lingering effect of exposure to supraoptimal density conditions” was speculated to account for this phenomenon. The classical technique for studying such phenomena is the P versus I curve. Such studies were carried out with T. suecica cultures grown in the smaller 9.2-m2 flumes. However, as the author noted, the results were “somewhat discouraging” as there was no difference as a function of dilution intervals, and productivities were only about 24 g/m2/d, much lower than reported with the larger flumes. Thus, this issue remained as a major focus of this project.

During the final year of the Hawaii ARPS project, the goal was to screen for additional algal species in the smaller flumes and to further study the effect of dilution intervals. Four species were tested in the 9.2-m2 flumes: Navicula sp., C. cryptica, C. gracilis, and Synechococcus sp. From prior work, photosynthetic efficiencies of 9.1% were reported with T. suecica, during a 78-day period, and 9.6% for 122 days with C. cryptica. With the three other organisms listed above, somewhat lower efficiencies were noted during shorter time periods: 7.8 % for Navicula sp., 8.5% for C. gracilis, and 8.6% for Synechococcus. Somewhat “surprisingly” (their characterization), they observed that in a 2-day batch growth mode, initial cell concentrations ranging from about 50 to 400 mg/L (AFDW) had no major effect on productivity. For C. cryptica, at an initial concentration of 40 mg/L at a depth of 12 cm, this would give an areal cell density of about 5 g/m2. For an equal daily productivity of 30 g/m2/d, averaged over 2 days, this would require the cells to divide 2.5 times the first day, and once the second day. Not impossible, certainly, but somewhat problematic. There is indeed some likelihood that some systematic measurement error influenced their productivity measurements.

"This report also described lipid induction by Si limitation by C. gracilis and C. cryptica. In both microalgae Si limitation greatly reduced overall productivities, and lipid productivities, even though lipid contents increased. Laws concluded that lipid productivities would be maximized by maximizing total biomass production." [173]

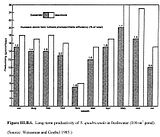

In the final paper, Laws et al., reported on long-term (13-month) production of C. cryptica in the large flume, with a 9.6% solar conversion efficiency reported with the foils and 7.5% without the foils, similar to earlier results with T. suecica. For 122 days, at optimal dilution (2- day batch cycle) productivity of about 30 g/m2/d was measured. This is, indeed, a high sustained productivity; on a year's basis, it equates to roughly 15g/m2/d (54.75 ton/hectare/year).

Conclusions of the Hawaii Project

This project evolved from one that focused on a demonstration of the ARPS concept using a single flume, to the investigation of fundamental issues in algal mass culture, using several smaller ponds and a simplified system design. In particular, this project reported very high productivities achieved by two methods: organized mixing in ponds (e.g., the foils), and optimal batch dilution (2- or 3-day intervals, depending on species). However, the basis for these productivity enhancements was speculative, and it proved difficult to demonstrate the reproducibility of these effects. The effects of foils could be better ascribed to degassing of oxygen from the ponds with foils (e.g., higher mixing power inputs) and the results from the 3- day dilution experiments to some uncontrolled factors, in addition to possible methodological problems.

None of the experiments under the Hawaii Project involved growing algae for longer than a year, which is why no final word on their (harvesteable) biomass productivity can be said. (One experiment was carried out for 13 months, but no yield data for it were reported.)

Laws continued his research with Electric Power Research Institute funding for 1 year, moving the system to Kona, Hawaii. No significantly different information was produced. However, Laws concluded

"that lack of land area, and high costs, would make such a process [growing algae in open ponds] impractical for fuel production in Hawaii." [174]

CALIFORNIA, 1981-1986

The objective of this second project was to demonstrate the functionality of a so-called High Rate Pond (HRP) system using agricultural irrigation waters and fertilizers as nutrients. The HRP was defined as a paddle wheel-mixed (approximately 10-20 cm/s), moderate depth (approximately 15-30 cm), algal production system. The R&D goal was to develop production technology for microalgae biomass with a high content of lipids. A detailed literature review concluded that the best option would be to use N limited (but not starved) batch cultures of green microalgae.

The system consisted of four 200-m2 and three 100-m2 ponds, along with three deep harvesting ponds and four water and effluent storage ponds. This system thus provided considerable flexibility for the testing of a large number of variables and algal species, at a scale that would allow some confidence in the scale-up of the results. The units were lined with 20 mil PVC, to allow complete mass balances.

Note on costs and energy balance: We wish to add an important note here: these ponds were lined with PVC, which brings us conceptually close to greenhouses used in terrestrial agriculture (purely speaking from the point of view of material inputs and costs). The biomass productivity of the algae obtained in the California ponds as well as in previous and later projects (between 30 and 50 ton per hectare per year) makes us conclude that the mere cost of the PVC makes such a system uncompetitive with ordinary, rainfed, open-air (sub)tropical agriculture. Tropical crops already yield far more biomass than algae (see below), and if they were to be grown in greenhouses, their productivity would be much higher still. This is why Jonas Van Den Berg's remark - "growing algae in reactors or in plastic ponds is like growing sugarcane in greenhouses, it makes no sense" - is not too far-fetched.

After an initial delay and a temporary loss of funding, the actual pond operations were initiated in August 1982.

The first inoculation of algae into one of the 100-m2 ponds consisted of a mixed Micractinium-Scenedesmus culture, which was soon lost:

"these algae settled out due to lack of flow deflectors, and the culture was soon dominated by a Selenastrum sp. Both biomass concentration and productivity were quite low. Without flow deflectors at the far end of the ponds (away from the paddle wheel) the hydraulics were so poor that the ponds exhibited almost zero productivity." [179]

This was due to the formation of large countercurrent eddies resulting in “dead zones,” where algal cells settled. After flow deflectors were installed, the pond was re-inoculated with an almost pure culture of Scenedesmus that had arisen spontaneously in one of the 12-m2 inoculum ponds. The culture remained well suspended and grew well.

However, a similar inoculation into a 200-m2 pond resulted in almost complete settling of the culture, caused by poor pond hydraulics, even with similar flow deflectors installed. This indicated that the hydraulics of the ponds are critical to the success of the process and further, that the hydraulics are not predictable from one scale to another, even within a factor of two. After two flow deflectors were installed around the bends in the 100-m2 ponds, these ponds exhibited much improved hydraulics, with few eddies or settling of algal cells.

In contrast, similar deflectors did not improve hydraulics perceptibly in the larger, 200-m2 ponds. Only after two more flow deflectors were installed at the end nearest the paddle wheels were satisfactory hydraulics observed in these larger ponds. A quantitative study of flow velocities was undertaken using a flow meter. The results were counterintuitive: flow velocities are higher on the inside than the outside of the channels. Clearly, pond hydraulics must be customized for each pond size and design to obtain even mixing.

"As expected, productivities were rather low in the initial experiments carried out during October and November 1982. Maximum productivities (measured for 2 days) were only about 9 g/m2/d and average productivities less than 5 g/m2/d." [179]

These initial experiments included assessment of species dominance, N limitations, and mixing velocities. Pond operations ceased by the end of November 1982 after poor results.

In 1983-1984, a new company, Microbial Products, Inc. (EnBio was dissolved when John Benemann left in 1983 for the Georgia Institute of Technology), continued the project. The pond system described earlier continued to be used for this project.

The objective was to obtain long-term productivity data with a pilot-scale system and generally demonstrate the requirements of large-scale algal mass cultivation

The first challenge was to obtain microalgal species that could be grown on the fresh to slightly brackish water available at the site:

"The common experience is that either inoculated strains from culture collections fail to grow in the outdoor ponds, or that they grow initially but become rapidly outcompeted by indigenous strains. A common practice is to make the best of a bad situation and cultivate the invading organisms instead." [180]

This was also the experience and approach of this project. After inoculation of Scenedesmus obliquus strain 1450 from the SERI Culture Collection, a strain of Scenedesmus quadricuada invaded. This turned out to be the most successful organism, cultivated for 13 months in fresh water and an additional 3 months in brackish. After an Oocystis sp. (Walker Lake isolate) was inoculated, a Chlorella sp. became dominant and was maintained (or maintained itself) for 2 months under semi-continuous dilution. However, some strains provided by SERI researchers could be grown for at least a few months outdoors, including an Ankistrodesmus falcatus and a freshwater Scenedesmus sp.

Productivity for S. quadricauda (see table 3) grown semi-continuously which is harvested every few days (a “sequential batch” growth mode), averaged about 15g/m2/day for the 8 month period of March through October, with monthly averaged solar conversion efficiency ranging from 1.2% to 2.2%. Typical biomass density just before harvest (that is on the 3rd dilution day) ranged from 60 to 100 g/m2, except for May, which recorded the highest standing biomass (160 g/m2) and productivity (20 g/m2/d). The continuously diluted cultures (diluted during the entire light period) exhibited approximately 20% higher productivity. Over a ten month period, the average productivity stood at 15g/m²/day (see table, click to enlarge), of which some 90% is harvesteable.

Productivity for S. quadricauda (see table 3) grown semi-continuously which is harvested every few days (a “sequential batch” growth mode), averaged about 15g/m2/day for the 8 month period of March through October, with monthly averaged solar conversion efficiency ranging from 1.2% to 2.2%. Typical biomass density just before harvest (that is on the 3rd dilution day) ranged from 60 to 100 g/m2, except for May, which recorded the highest standing biomass (160 g/m2) and productivity (20 g/m2/d). The continuously diluted cultures (diluted during the entire light period) exhibited approximately 20% higher productivity. Over a ten month period, the average productivity stood at 15g/m²/day (see table, click to enlarge), of which some 90% is harvesteable.The main conclusions of the extensive experimental program were interesting. They included:

1. Productivities of 15 to 25 g/m2/d were routinely obtained during the 8-month growing season at this location. However, higher numbers were rarely seen. Algae were not grown during winter months.

2. Continuous operations are about 20% more productive than semi-continuous cultures, but the latter densities are much higher, a factor in harvesting.

3. Culture collection strains fare poorly in competition with wild types.

4. Temperature effects are important in species selection and culture collapses, including grazer development.

5. Nighttime productivity losses increased to 10% to 20 % in July, when grazers were present; nighttime respiratory losses were high only at high temperatures.

6. There is a significant decrease in productivity in the afternoons, compared to the mornings, in the algal ponds.

7. Oxygen levels can increase as much as 40 mg/L, over 450% of saturation, and

high oxygen levels limit productivity in some strains but not others. Oxygen

inhibition was synergistic with other limiting factors (e.g., temperature).

[...]

9. Mixing power inputs were small at low mixing velocities (e.g., 15 cm/s) but increased exponentially. Productivity was independent of mixing speed.

10. The strains investigated in this study did not exhibit high lipid contents even upon N limitation.

11. The transfer of CO2 into the ponds was more than 60% efficient, even though the CO2 was transferred through only the 20-cm depth of the pond.

12. Harvesting by sedimentation has promise, but was strain specific and was increased by N limitation.

13. Initial experiments demonstrated that media recycle is feasible.

14. Project end input operating costs for large-scale production (at $50/mt of CO2, 70% use efficiency, etc.) was $130/mt of algae, of which half was for CO2 and one-third for other nutrients, with pumping and mixing power only about $10/mt.

This project answered a number of issues that had been raised about this process. One initially controversial observation was the finding that mixing speed had no effect on productivity. However, this experiment used a strain of Chlorella that did not settle, and care was taken to keep other parameters identical (in particular pH and pO2 levels). Thus, the increased productivities seen in some experiments (e.g., those of Hawaii), could possibly be accounted for by differences other than those of mixing, such as changes in outgassing of O2.

From the perspective of large-scale biomass production, one conclusion from this research was that

"mixing power inputs make any mixing speed much above about 30 cm/s impractical, as the energy consumed would rapidly exceed that produced. The rate of mixing should only be between about 15 and 25 cm/s, sufficient to keep cells in suspension and transfer the cultures to the CO2 supply stations in time to avoid C limitations in large-scale (>1-ha) ponds." [181]

For low-cost production higher productivities would reduce capital, labor, and some other costs, but nutrient (e.g., CO2) related costs would not change. This suggested the need for low-cost CO2, and other nutrients, as well as a high CO2 utilization efficiency. Efficient utilization of CO2 appeared feasible based on the results obtained with even this unoptimized system.

Another major conclusion was that

"competitive strains would be required to maintain monocultures. The need for feedback from the outdoor studies to development of laboratory screening protocols was a major recommendation. Specifically, the relatively controllable parameters of CO2, pH, and O2 were of interest in determining species survival and culture productivity. Also, harvesting was identified as a specific area for further research. Finally, lipid induction remained to be demonstrated."[182]

These were the general objectives during the final year of this project.

In 1985-86, numerous microalgal strains were obtained from the SERI Culture Collection and tested in small-scale, 1.4-m2, ponds. All strains could be grown quite successfully in these very small units, although some, such as Amphora sp., did not survive more than 2 or 3 weeks before they were displaced by other algae.

Cyclotella displaced Amphora under all conditions tested, even though Amphora was the most productive strain, producing 45 to 50 g/m2/d in very short-term experiments. The green algae, e.g. Chlorella or Nannochloropsis, also could not be grown consistently. Their productivities were among the lowest, about 15 g/m2/d (similar to that in the prior year).

"Thus, one fundamental conclusion was that productivity is not necessarily correlated with dominance or persistence." [185]

A significant factor in pond operations was the oxygen level reached in the ponds, which influenced productivity and species survival. Ponds were operated with air sparging (and antifoam) to reduce DO levels, from typically 400% to 500% of saturation without air sparing, to 150% to 200% of saturation with sparging. Foaming, caused by air sparging, was still was a problem in some cases, as with the Cyclotella. However this alga exhibited approximately the same productivity with or without sparging despite the 20%-30% opaque foam cover, suggesting some positive effect of the lower pO2. For other algal species productivity differences of 10% to 20% were noted, and for some (e.g., C. gracilis), no specific effect of high versus low DO was noted.

These outdoor results were reproducible enough to detect differences of greater than about 10% between treatments. The major result of this project was that productivities were 50% to 100% higher than the previous year, with some species of diatoms producing 30 to 40 g/m2/d (AFDW, efficiency about 6% to 9% of PAR, or 3% to 4.5% total solar). The green algae were, as mentioned earlier, less productive than the diatoms.

A more detailed study of oxygen effects was also carried out in the laboratory, avoiding the confounding factors of CO2 supply, temperature, and light intensity. In general the diatoms were insensitive to high DO; most, but not all, of the green algal strains exhibited marked inhibition by high oxygen levels:

"None of the oxygen-sensitive algae could be grown outdoors, suggesting this as a major factor in species dominance and productivity." [185]

Laboratory studies were also carried out at both high light intensity and high DO, to determine the synergism between these factors. Both the apparent maximum growth rate and dense culture productivity were determined for comparisons. Higher levels of DO intensified the inhibitory effects of higher light observed in some cases. This was true in particular for productivity, with growth rates also affected. Of course, the actual density of the culture is a major factor determining productivity, and dense cultures avoid most, if not all, the deleterious effects of high

light intensity. High O2 and low CO2 are other factors influencing the response to high light, with O2 being more inhibitory at both low CO2 and high light levels. High oxygen also affects chlorophyll content, although this effect is most pronounced at low light intensities where chlorophyll levels are 50% higher compared to high light intensities.

Outdoor experiments were carried out to determine the effect of low CO2 (25 µM) and high (9-10) pH, which would be experienced in algal mass cultures, at least temporarily. Compared to the control cultures, one strain was not inhibited even at pH 10, two not at pH 9, and two were inhibited by about 33% at this pH, compared to the control at pH 8. Lowering pCO2 also resulted in similar levels of inhibition for the other strains. A role for bicarbonate in growth at high pH was established from the data, with metabolic costs estimated at about one-third of productivity, a major factor. This requires further investigation.

One strain, a Cyclotella species, exhibited an increase of lipid content of more than 40% of dry weight upon Si limitation. However, lipid productivity (9 g/m2/d), was not significantly different between Si-deficient and the Si-sufficient controls, because of the high productivity of the Si sufficient culture. Optimizing for lipid productivity was considered possible, but requires more detailed study.

Perhaps most important, the data and simulations also suggest that maximizing productivity at an acceptable CO2/pH combination from the perspective of outgassing and CO2 loss from the ponds is possible, with operations above pH 8.0 required (for an alkalinity of 32 meq/L, higher for higher alkalinities) to avoid wasting of CO2.

Laboratory studies were also carried out during this project. These included a study of light conversion efficiencies that concluded that at low light intensities very high light conversion efficiencies can be achieved (near the theoretical maximum of about 10 photons/CO2 fixed).

However, these and other laboratories studies carried out during this project would require a much longer review than possible here.

Note on costs: An important note on costs is required here: the California project investigated different harvesting techniques for microalgae cultures. To enhance algae settling, both polymers, FeCl3 and cross-flow filtration were studied. The flocculation technique (getting the algae to flock together so they can be harvested easily) required the addition of organic flocculants at about 2 to 6 g/kg and FeCl3 at about 15 to 200g/kg of algal biomass to remove 90% or more of the algal cells. Because of the high cost of the organic flocculants, costs were comparable for both flocculants tested. The organic polymers were also deemed to have significant potential for improvement and optimization. Cross-flow filtration, though effective, was estimated to be too expensive. In short, a considerable amount of costly inputs is needed to harvest the algae. No lifecycle study was ever presented which included all these costs and the energy balances of the inputs.

In conclusion, this project significantly advanced the state-of-the art of microalgae biomass production, and provided the basis for the Outdoor Test Facility, the ASP's final project.

ISRAEL

In the mid-1980s, the ASP researchers collaborated with scientists in Israel, in three separate projects. All these experiments involved the same idea: growing algae in (very small) open ponds in the desert. It would take us too far here to discuss the results of these projects, but for basic data, we refer to Table 1, which presents an overview of all the field trials initiated under the ASP.

Some key findings included:

-the fact that in chemostat tests (these are lab tests) “nitrogen limitation does not induce the production and accumulation of lipids,” but the “algae attain a low protein-carbohydrate ratio.” Previous reports in the literature describing lipid accumulation in algae induced by N limitation were attributed to trace element limitations.

-two cultures, C. gracilis and Nannochloris atomus grown in laboratory chemostats and in 0.35-m2 outdoor “microponds” attained productivities of 40 g/m2/d (C. gracilis) during June-August, which decreased by a bout half during the winter. Lipid contents in the N-sufficient algal cells increased almost as much, reproducing the low-temperature effect on lipid content seen in the laboratory cultures.

-attempts were also made to increase lipid production by Si limitation, but this was unsuccessful due to rapid contamination with green algae.

NEW MEXICO, OUTDOOR TEST FACILITY, 1987-1990

After the above noted projects carried out in Hawaii, Israel and California, the ASP decided to hold a competition for the development of a larger process development outdoor test facility (OTF) located in the southwestern United States. Two independent designs and proposals were commissioned, one consisting of enclosed production units; the other of open ponds, similar to the design tested in California.

The latter design won the competition, with a proposed facility consisting of two 1,000-m2 ponds, one plastic lined and another unlined, as well as supporting R&D using six small, 3-m2 ponds, continuing and extending the work carried out in the prior projects in California.

Although the proposal recommended establishing this facility in Southern California, the ASP selected a site in Roswell, New Mexico to establish the OTF. The project was located at an abandoned water research facility. Roswell has high insolation, abundant available flatland and supplies of saline groundwaters. The primary limitation of this site was temperature, which, in retrospect, turned out to be too low for more than 5 months of the year for the more productive species identified during the prior project.

The objective of the first year of the research at this new site was to initiate a species screening effort at this site with the small 3-m2 ponds, which were installed while designing and constructing the larger facility. A major objective of this project was to identify cold weather adapted strains. Building the large system required installation of two water pipelines of 1,300-m in length (15 and 7.5 cm, for brackish and fresh waters). The ponds were about 14 x 77 m, with concrete block walls and a central wooden divider. The paddle wheels were approximately 5-m wide, with a nominal mixing speed of 20 cm/s, and a maximum of 40 cm/s. Carbonation was achieved with a sump that allowed counterflow injection of CO2, to achieve high (90%+) absorption of CO2. One pond was plastic lined; the other had a crushed rock layer. The walls were cinder block. A 50-m2 inoculum production pond was included.

During the first year of the project (Weissman et al. 1988), all experimental work was carried out using the small ponds, which allowed essentially fully automatic operation and continuous dilution, as well as heating if needed. The objectives were to determine long-term productivity and stability for this site with previously studied and new species. Five of the strains inoculated into the 3-m2 ponds were successfully cultivated, including two that derived from local isolates (one of which had invaded these ponds).

Three of the culture collection strains could not be cultivated stably in the small ponds.

"Productivities in the summer month of August reached 30 g/m2/d for C. cryptica CYCLO1, but decreased to about half this level in September and October. At this point, M. minutum (MONOR2) was used, as this is a more cold-tolerant organism. By November productivity of MONOR2 fell to about 10 g/m2/d, and was very low (3.5 g/m2/d) in December in unheated ponds. Remarkably, despite these ponds freezing over repeatedly, the culture survived and exhibited some productivity." [195]

During August and September, productivities for CYCLO1 and Amphora sp. exhibited short-term excursions above 40 g/m2/d. Faulty data are not suspected.

The large-scale system was completed by the second year. But some problems were encountered: the spongy clay at the site did not compact well, resulting in an uneven pond bottom. This made it difficult to clean and drain the ponds, and resulted in settling and sedimentation of solids.

Significant differences were noted between the lined (north) and unlined (south) ponds, in terms of mixing velocities, head losses, and roughness coefficients.

Conclusions for the OTF project

The final report in this series on the New Mexico OTF operations, reported on the demonstration of productivity for the two large ponds for 1 full year, continuation of the small-scale pond operations, and improvements in mixing and carbonation.

1. One major improvement in the system was an automated data recording and operations system.

2. Mixing was improved by improving the flow deflectors and increasing operating depths from 15 to 22.5 cm, which is probably a better depth for large-scale systems.

3. Culture instability was a problem, particularly in spring because of greater temperature fluctuations, and resulted in low average productivity of only 7 g/m2/d for March through May. In contrast, the average productivity was 18 g/m2/d for June through October, decreasing to 5-10 g/m2/d in November (depending on onset of cold weather), and only about 3 g/m2/d in the winter months. Overall productivity, including 10%-15% down-time for the ponds for repairs and modifications, was 10 g/m2/d, only one-third of ASP goals.

4. A major conclusion from this work is that scale-up is not a limitation with such systems. Climatic factors are the primary ones that must be considered in their siting.

5. A countercurrent flow injection system was installed in the sumps resulting in a carbonation system that was essentially 100% efficient in CO2 transfer. Overall CO2 utilization was higher than 90%.

6. Species stability in the lined and unlined pond exhibited no significant difference. This work clearly established the feasibility of using unlined ponds in microalgae cultivation. This was a critical issue, as plastic lining of ponds is not economically feasible for low-cost production.

7. In the small 3-m2 systems, two variables were investigated: Si supply and pH. Both are major cost factors in pond operation, due to sodium silicate costs and CO2 outgassing. They affect overall productivity as well as lipid production. For Cyclotella, for example, productivity was about 20 g/m2/d at pH 7.2 or 8.3, but only 15 g/m2/d at pH 6.2. As the higher pH range is preferred, where CO2 outgassing is minimal, this demonstrates the feasibility of operating such cultures within the constraints of a large-scale production system. Si additions could be halved with only a modest decrease in productivity, suggesting that Si supply could be reduced, particularly if low Si-containing diatoms are cultivated. Also Si limitation can be used to induce lipid production, as was demonstrated during this project, with lipid biosynthesis increasing as soon as intracellular Si content dropped, with a 40% lipid content being achieved. However, overall, lipid productivity did not increase as CO2 fixation limitation also set in. This remains as a major issue for future research.

Algae versus tropical energy crops

Tropical energy crops are known for their high biomass productivities. They come in different forms (grasses, trees, annual and permanent crops) and under such names as eucalyptus, Arundo donax, sorghum, sugarcane, oil palm, sweet potato, cassava or sago.

The ASP produced very few field trials in which algae were successfully grown continuously for periods of over a year. In fact, most experiments lasted a few days or weeks only (see table 1). Since algae are highly sensitive to changes in temperature, monthly or weekly biomass productivity data (e.g. high yields during summer months) can not be extrapolated into yearly data. Only two series of data allows us to make a comparison with the yields of tropical crops. They are the data reported in the "large scale" study of 1977-79 and the data from the OTF trials in New Mexico.

Table 4 shows that tropical energy crops yield considerably larger amounts of biomass than algae cultures. Several crops easily produce twice the amount of biomass.

Table 4 shows that tropical energy crops yield considerably larger amounts of biomass than algae cultures. Several crops easily produce twice the amount of biomass.It should be noted that the data for the tropical crop yields in Table 4 refer to the "phytomass" of those crops. That is the entire biomass of the plants (including roots or rhizomes). Still for the majority of these crops (the exception being Arundo donax), the bulk of this phytomass is actually harvesteable and can be used as a bioenergy feedstock.

Besides differences in yields, some broad points for comparisons between algae production systems and 'traditional' terrestrial agriculture are the following:

-species control and scale:

algae cultures tend to be unstable and can be colonized fairly easily by more powerful algae; these biologically stronger species are not necessarily suitable for biofuel production (e.g. their lipid contents are too low). Now in traditional tropical agriculture, pest and diseases are a comparable problem: a plantation or a sugarcane field can be invaded with weeds or pests. But relatively simple techniques (pesticides, herbicides and phytopathological strategies using natural predators) can be applied to the crops. In open algae ponds this would be extremely difficult.

Moreover, experience with terrestrial agriculture has allowed farmers to estimate the disease, pesticide and herbicide infestation risks involved in establishing vast monocultures. For algae, the largest facilities ever usedhad a surface of a mere 0.1 hectares, with most of them being "micro-ponds" of a few square metres. No studies or projections exist that allow algae-culturalists to estimate the risk of colonisation and destabilisation of large algae monocultures. Given the high rate of destruction of cultures grown in "micro-ponds", it is not unreasonable to assume that this rate increases as a function of the size of the ponds. As yet, there are not enough datasets to look for a correlation between pond-size and the risk of culture-loss. But one thing is certain: the ultra-large scale production schemes ("replacing all U.S. diesel demand with algae grown in one big pond facility located in the Sonoran desert") that have been proposed are faced with this important lack of knowledge on phytopathological risks involved in large scale algae-culture.

-risk of species contamination and the uncontrolled spread of genetically modified algae:

from the ASP we learn that mass algae production is not likely to be feasible unless genetically modified algae are engineered which are stable, contain a high amount of lipids and can be harvested easily. The problem with such a development would obviously be contamination of water bodies not destined for biofuel prodution. The genetically altered algae species would be so strong, that they would easily destroy species that thrive naturally in water bodies. The existing algae colonies in natural water bodies are often caught in a fragile balance, with 'predators' fighting each other, limiting the overall colonisation of the water body. A genetically altered species could unsettle this balance and cause a major pest problem.

The same can of course be said of genetically altered energy crops. But it is clear that biomass yields of tropical crops are high enough to maintain a positive energy balance; in theory, no genetically modified crops are needed to produce satisfactory amounts of biomass.

-harvesting problems:

modern tropical agriculture (let us take the sugarcane industry as an example) is highly mechanised when it comes to harvesting and processing biomass. Harvesting techniques for algae have not attained the same level of perfection. The tried technologies (membranes, bioflocculation) are a limiting factor when it comes to choosing the best algae; some interesting micro-organisms are physically too small to be practically harvesteable by membranes; whereas the flocculation technique does not yield consistent results with all species. Moreover, flocculants are very expensive and some species need a high amount of them in order to flocculate.

-opportunity costs, system flexibility and crop portfolios

A major disadvantage of algae production systems is that once the investments in the technologies have been made, they must be used, even when the economics change radically. This is not the case in terrestrial agriculture (at least not when it involves annual crops), where farmers can switch between crops and markets, and choose to grow crops that promise to make most profits depending on market predictions. In terrestrial agriculture assets (like land and machinery) can be used for a wide variety of crops and products. This allows for flexibility and for adapting choices to market opportunities.

Energy farmers can produce feedstocks for biofuels one year, and decide to grow food crops the next. This would be hard to achieve with algae production systems, which have to be finetuned and designed to accomodate a specific range of species, catering to a very specific market. The volatility of oil prices influences the volatility of bioenergy markets and is now ultimately influencing the market for food products. Terrestrial farmers can switch between the two. Algae-culturalists can not, which entails a definite risk.

All in all, algae-culture does not have to be seen as a strict competitor with energy crops. Algae ponds can be located in arid regions not suitable for agriculture (such as deserts). The only problem is their high production costs (on an energy equivalent basis) and the lack of flexibility of the production system, compared to those of (tropical) terrestrial energy crops.

Algae for biohydrogen and biogas production

The ASP focused on the production of biodiesel from algae. However, the micro-organisms have been studied as potential feedstocks for the production of gaseious fuels such as hydrogen and biogas (biomethane). In the 1950s and 1970s, several field trials aimed at obtaining biogas were carried out (mentioned in the document we are referring to here) with encouraging results.

"The idea of producing methane gas from algae was proposed in the early 1950s. These early researchers visualized a process in which wastewater could be used as a medium and source of nutrients for algae production. The concept found a new life with the energy crisis of the 1970s. DOE and its predecessors funded work on this combined process for wastewater treatment and energy production during the 1970s. This approach had the benefit of serving multiple needs—both environmental and energy-related. It was seen as a way of introducing this alternative energy source in a near-term timeframe." [3]

Algae were grown on the sludge of waste water management facilities, in open ponds, after which their biomass was harvested and used as a substrate in a biogas digester. It was shown that many species make for a good subtrate for anaerobic fermentation:

"The concept of microalgae biomass production for conversion to fuels (biogas) was first suggested in the early 1950s. Shortly thereafter, Golueke and coworkers at the University of California–Berkeley demonstrated, at the laboratory scale, the concept of using microalgae as a substrate for anaerobic digestion, and the reuse of the digester effluent as a source of nutrients.

Oswald and Golueke presented a conceptual analysis of this process, in which large (40-ha) ponds would be used to grow microalgae. The algae would be digested to methane gas used to produce electricity. The residues of the digestions and the flue gas from the power plant would be recycled to the ponds to grow additional batches of algal biomass. Wastewaters would provide makeup water and nutrients. The authors predicted that microalgae biomass production of electricity could be cost-competitive with nuclear energy. This concept was revived in the early 1970s with the start of the energy crisis. The National Science Foundation–Research Applied to National Needs Program (NSF-RANN) supported a laboratory study of microalgae fermentations to methane gas (Uziel et al.1975). Using both fresh and dried biomass of six algal species, roughly 60% of algal biomass energy content converted to methane gas." [145]

However, the researchers found that the organically rich sludge on which the algae were fed, yielded more methane than the algae that had grown on it. So the entire venture was seen as inefficient: why make the detour of converting a prime biogas substrate that yields reasonable quantities of methane, into a substrate that yields less?

Even though it would take us too far to delve into the potential of hydrogen producing algae, some past and more recent developments are worth noting. The oil crisis in 1973 already prompted research on biological hydrogen production, including photosynthetic production, as part of the search for alternative energy technologies. Green algae were known as light-dependent, water-splitting catalysts, but the characteristics of their hydrogen production were not practical for exploitation.

Hydrogenase is too oxygen-labile for sustainable hydrogen production: light-dependent hydrogen production ceases within a few to several tens of minutes since photosynthetically produced oxygen inhibits or inactivates hydrogenases. A continuous gas flow system designed to maintain low oxygen concentrations within the reaction vessel, was employed in basic studies, but has not been found practically applicable.

Scientists later found that a particular species of algae, Scenedesmus, does produce molecular hydrogen under light conditions after being kept under anaerobic and dark conditions.

Basic studies on the mechanisms involved in hydrogen production determined that the reducing power (electron donation) of hydrogenase does not always come from water, but may sometimes originate intracellularly from organic compounds such as starch. The contribution of the decomposition of organic compounds to hydrogen production is dependent on the algal species concerned, and on culture conditions. Even when organic compounds are involved in hydrogen production, an electron source can be derived from water, since organic compounds are synthesized by oxygenic photosynthesis. The reason for hydrogenase inactivity in green algae under normal photosynthetic growth conditions is unclear. Hydrogenase is thought to become active in order to excrete excess reducing power under specific conditions, such as anaerobic conditions.

Very high (10 to 20%) efficiencies of light conversion to hydrogen have been reported, based on PAR (photosynthetically active radiation which includes light energy of 400-700nm in wavelength). Recent findings show that a kind of "short circuit" of photosynthesis exists, whereby hydrogen production and CO2 fixation occur by a single photosystem (photosystem II only) of another species, a Chlamydomonas mutant.

Green algae are applicable in another method of hydrogen production. Scenedesmus produces hydrogen gas not only under light conditions, but also fermentatively under dark anaerobic conditions, with intracellular starch as a reducing source. Although the rate of fermentative hydrogen production per unit of dry cell weight, was less than that obtained through light-dependent hydrogen production, hydrogen production was sustainable due to the absence of oxygen. On the basis of experiments conducted on fermentative hydrogen production under dark conditions, other scientists have proposed hydrogen production in a light/dark cycle. According to their proposal, CO2 is reduced to starch by photosynthesis in the daytime (under light conditions) and the starch thus formed, is decomposed to hydrogen gas and organic acids and/or alcohols under anaerobic conditions during nighttime (under dark conditions).

The technological merits of this proposal include the fact that oxygen-inactivation of hydrogenase can be prevented through maintenance of green algae under anaerobic conditions, nighttime hours are used effectively, temporal separation of hydrogen and oxygen production does not require gas separation for simultaneous water-splitting, and organic acids and alcohols can be converted to hydrogen gas by photosynthetic bacteria under light conditions. A pilot plant using a combined system of green algae and photosynthetic bacteria was operated within a power plant of Kansai Electric Power Co. Ltd. (Nankoh, Osaka, Japan). Researchers at this plant recently proposed chemical digestion of algal biomass as a means of producing substrates for photosynthetic bacteria, thus improving the yield of starch degradation.

Finally, cyanobacteria have also been found to produce hydrogen gas auto-fermentatively under dark and anaerobic conditions. Spirulina species were demonstrated to have the highest activity among cyanobacteria tested. The nature of the electron carrier for hydrogenase in cyanobacteria is still unclear.

All in all, hydrogenases have been purified and partially characterized in only a few cyanobacteria and microalgae.