The bioeconomy at work: bioplastics from plant-based oils

The bioplastics and biopolymers discussed earlier in our overview are mainly based on the fermentation of starches and sugars. But a considerable amount of research is underway on using straight vegetable oils instead, as substitutes for petroleum.

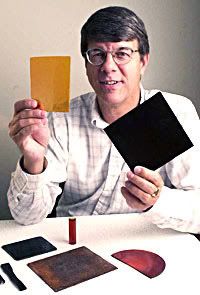

The bioplastics and biopolymers discussed earlier in our overview are mainly based on the fermentation of starches and sugars. But a considerable amount of research is underway on using straight vegetable oils instead, as substitutes for petroleum.Richard Larock, professor of chemistry at Iowa State University, is amongst those researchers. His work has resulted in the production of plastics from soybean and corn oil that are considerably cheaper than their petrochemical counterparts.

One of Larock's plant-based materials is reinforced with glass fibers, the kind of tough bioplastic he and his industrial collaborators will use to develop, test and manufacture new hog feeders. The professor says his research project is very much tied to Iowa's culture - after all, the state is America's leading producer of corn, soybeans and pork.

Larock has invented and patented a process for producing various bioplastics from inexpensive natural oils, which make up 40 percent to 80 percent of the plastics. Larock said the plastics have excellent thermal and mechanical properties and are very good at dampening noises and vibrations. They're also very good at returning to their original shapes when they're heated.

"This project should create new technology and jobs, expand opportunities for bio-based industries and agricultural suppliers, decrease our dependence on oil, strengthen the agricultural economy of Iowa, utilize ISU patented technology, provide new markets for farmers and marry new agricultural product development with sophisticated manufacturing skills and the knowledge to commercialize these projects." - Professor Richard Larock, Iowa State University.

The project is partially supported by a grant of $96,000 from the Grow Iowa Values Fund, a state economic development program. Larock is working with AgVantage Inc., a Rockford, Ill., company with manufacturing facilities in Iowa, and R3 Composites, a Muscatine manufacturer:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: biopolymers :: bioplastics :: vegetable oil :: bioeconomy ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: biopolymers :: bioplastics :: vegetable oil :: bioeconomy :: Ron Hagemann, a principal with AgVantage, said designs for a bioplastic hog feeder have been drawn up. The designs include radio frequency identification technology that can monitor and record the feeding habits of individual hogs. Molds for the high-tech feeders should be completed later this year and prototypes should be ready for testing in a hog building next spring. If all goes well, he said a product should be ready for commercialization by the end of next year.

Hagemann said the feeders' biggest advantage in the marketplace will be material costs. Corn and soybean oils are significantly cheaper than petrochemicals. And that's particularly true when oil prices are high.

Hagemann said he expects this project to be a very good test of Larock's plastics.

Hogs, after all, aren't known for being gentle with their feeders.

"I've told Richard that if we can do this, it's all downhill from here," Hagemann said.

But Larock isn't stopping with the feeder project. He's looking at adding other low-cost agricultural ingredients to his bioplastics. He's now studying whether distillers dried grains, a co-product of ethanol production that's sold as animal feed, can add strength to his bioplastics.

-------------------

-------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

0 Comments:

Post a Comment

Links to this post:

Create a Link

<< Home