The bioeconomy at work: nanotech process developed to make green lubricants from palm biodiesel by-product

The African oil palm is a crop that yields an enormous amount of biomass (earlier post) that can be used for the production a wide range of plant-based products. Currently, only the oils extracted from the fresh palm fruits are considered to be a commodity, but this situation is changing very rapidly. Waste-streams from plantations and from processing operations have become valuable biomass fuels in themselves, that are increasingly being used for power generation at the processing plants, instead of fossil fuels (earlier post). Liquid waste-streams from the oil extraction process are being used efficiently for the production of biogas (earlier post). Finally, ligno-cellulosic plantation and processing residues can be utilized either as a feedstock for next-generation ethanol (earlier post), or for the production of plant-based materials such as bioplastics [on bioplastics from oil palm residues, see this document *.pdf].

The African oil palm is a crop that yields an enormous amount of biomass (earlier post) that can be used for the production a wide range of plant-based products. Currently, only the oils extracted from the fresh palm fruits are considered to be a commodity, but this situation is changing very rapidly. Waste-streams from plantations and from processing operations have become valuable biomass fuels in themselves, that are increasingly being used for power generation at the processing plants, instead of fossil fuels (earlier post). Liquid waste-streams from the oil extraction process are being used efficiently for the production of biogas (earlier post). Finally, ligno-cellulosic plantation and processing residues can be utilized either as a feedstock for next-generation ethanol (earlier post), or for the production of plant-based materials such as bioplastics [on bioplastics from oil palm residues, see this document *.pdf].The most obvious of markets for palm oil is of course that of biodiesel. But to make palm based biodiesel useable in the cold climates of the Northern hemisphere, it has to be chemically transformed so that its cloud point is brought down. The Malaysian Palm Oil Board recently developed a patented process that achieves this transformation in a relatively efficient manner, while an Ecuadorian company did so too (earlier post).

However, the process aimed at increasing the cold tolerance of the fuel, is based on physically removing a fraction of the biodiesel, resulting in a by-product that may make up 15% of the primary feedstock. This reduces the overall energy balance of the fuel and negatively affects its economics.

Australian nanotechnology company Nano-Chemical Systems Holdings, however, announced today that it has developed a process that makes use of the waste fraction to make renewable automotive and aviation oils and lubricants with a high added value. The company's patent pending process is based on the immersion of nano-sized molybdenum metal ball bearings to produce the oils and lubricants:

biomass :: bioenergy :: biofuels :: energy :: sustainability :: oil palm :: fuel properties :: ethanol :: biodiesel :: nanotechnology ::nanobiotechnology :: lubricants :: bioeconomy ::

biomass :: bioenergy :: biofuels :: energy :: sustainability :: oil palm :: fuel properties :: ethanol :: biodiesel :: nanotechnology ::nanobiotechnology :: lubricants :: bioeconomy ::These enhanced oils and lubricants give the consumer the advantages of longer machine life from reduced ware and superior performance at high temperatures and pressures associated with "moly" lubricants. The oils and lubricants are highly biodegradable and have the promise of non-hazardous waste disposal. These new oils and lubricants also offer the promise of reduced crank case and other lubricant emissions to improve air quality.

The oils and lubricants are a solid marketing complement to ethanol-fueled automobiles. It only makes sense to use "Green", "Clean technology" oils and lubricants once the car owner has made the commitment to a renewable, environmentally friendly energy solution. There are a number of testing, process, specification, approval, supply channel and distribution channel issues that need to be overcome before these oils and lubricants can be offered for sale.

Article continues

------------------------

------------------------

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

Spanish company Ferry Group is to invest €42/US$55.2 million in a project for the production of biomass fuel pellets in Bulgaria.

The 3-year project consists of establishing plantations of paulownia trees near the city of Tran. Paulownia is a fast-growing tree used for the commercial production of fuel pellets.

In a development of major importance for the future of the biobased economy, plant biologists at the University of Connecticut have

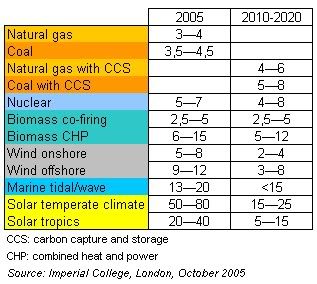

In a development of major importance for the future of the biobased economy, plant biologists at the University of Connecticut have  Some notes have to be added to this projection. First of all, the data are from a

Some notes have to be added to this projection. First of all, the data are from a  Two leading car manufacturers will be present at the

Two leading car manufacturers will be present at the

Monday, February 26, 2007

Documentary about biofuels: "The Brazilian Revolution"

The industrial-scale, technology and science-driven ethanol sector in Brazil is over 30 years old. Currently, more than 70% of all cars in the country use the fuel which is made primarily from sugarcane. The biofuel is both cheaper and considerably less polluting than gasoline. Moreover, contrary to its fossil counterpart, it is renewable and the expansion of its production can be planned.

The documentary follows José, a small sugarcane farmer in São Paulo state who has been growing the crop all his life to make sugar from it. Thirty years ago, he started supplying one of Brazil's first ethanol plants.

In Brazil, the production of ethanol benefits from optimal conditions: an abundance of land, sun and water, but also of a scientific effort supported by the government. In private and state-run laboratories and institutions, researchers are developing new crop varieties, new processing and logistical technologies with which to increase the productivity and efficiency of the sector. Car manufacturers in Brazil soon followed and today all of them have so-called 'flex-fuel' models on the market. Brazil's state-owned oil giant, Petrobras, is a major player in the sector and supporter of the industry.

The Lula government has created a set of policies that is explicitly aimed at pulling small farmers into the sector: large companies who source their feedstocks from smallholders, receive tax breaks. Several multinationals have already accepted the deal. Extension services have been created aimed at training and informing the smallholders about the biofuels program and its lucrative economic opportunities. And with a promising project in the northern province of Natal, Petrobras is setting the example by buying raw materials for the production of biodiesel from family-run farms only.

The documentary can be watched on ARTE, tonight at 10.20pm CET, and will be shown again on Friday, March 2 at 3.10pm. An online version is to follow later [entry ends here].

Article continues

posted by Biopact team at 8:59 PM 0 comments links to this post